Thin film transistor array base and its pixel structure

A technology of thin film transistors and array substrates, which is applied in the field of active element array substrates, can solve problems such as resistance and capacitance hysteresis, color shift and insufficient color saturation, and achieve the effect of improving resistance and capacitance hysteresis and enhancing display effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

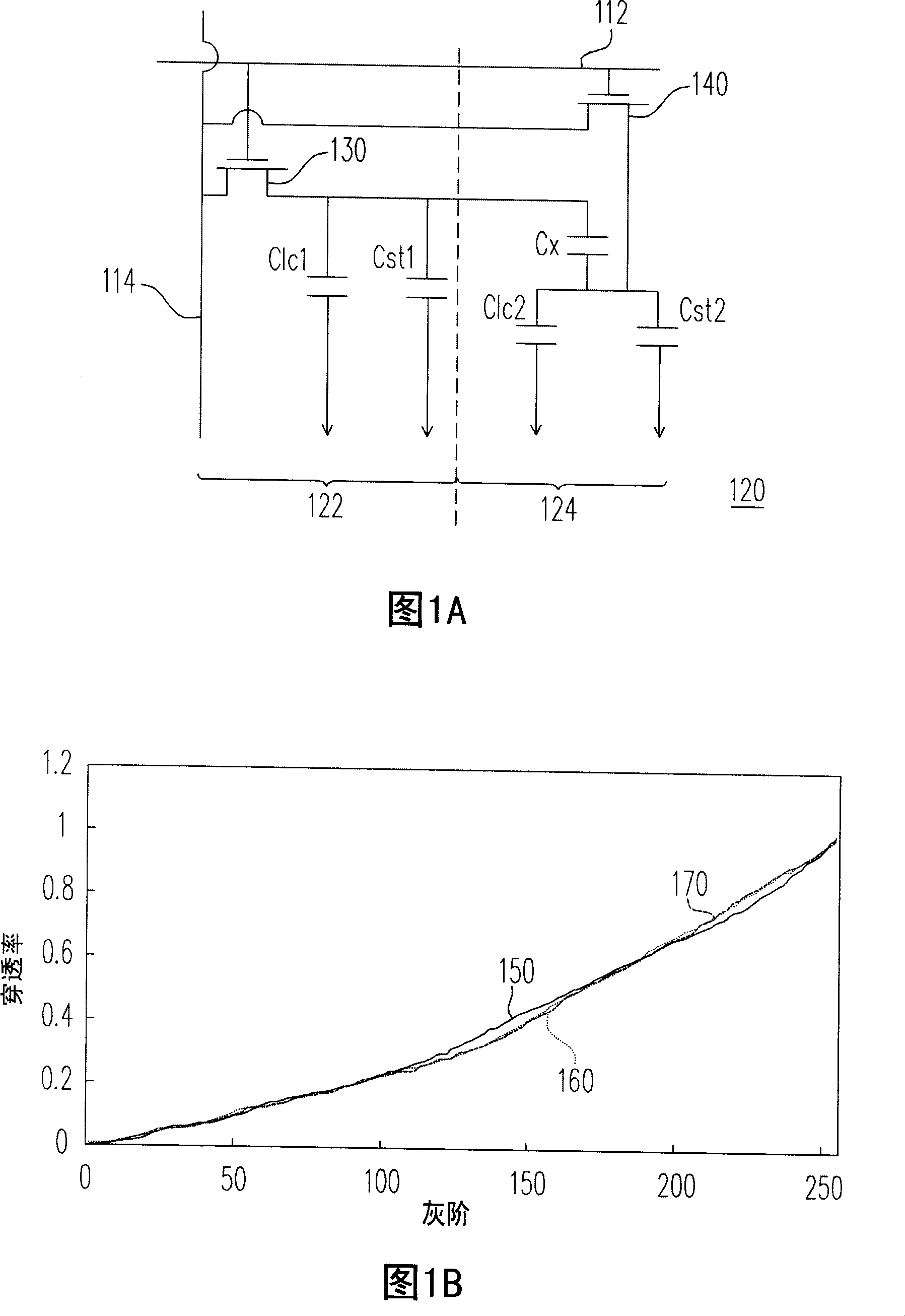

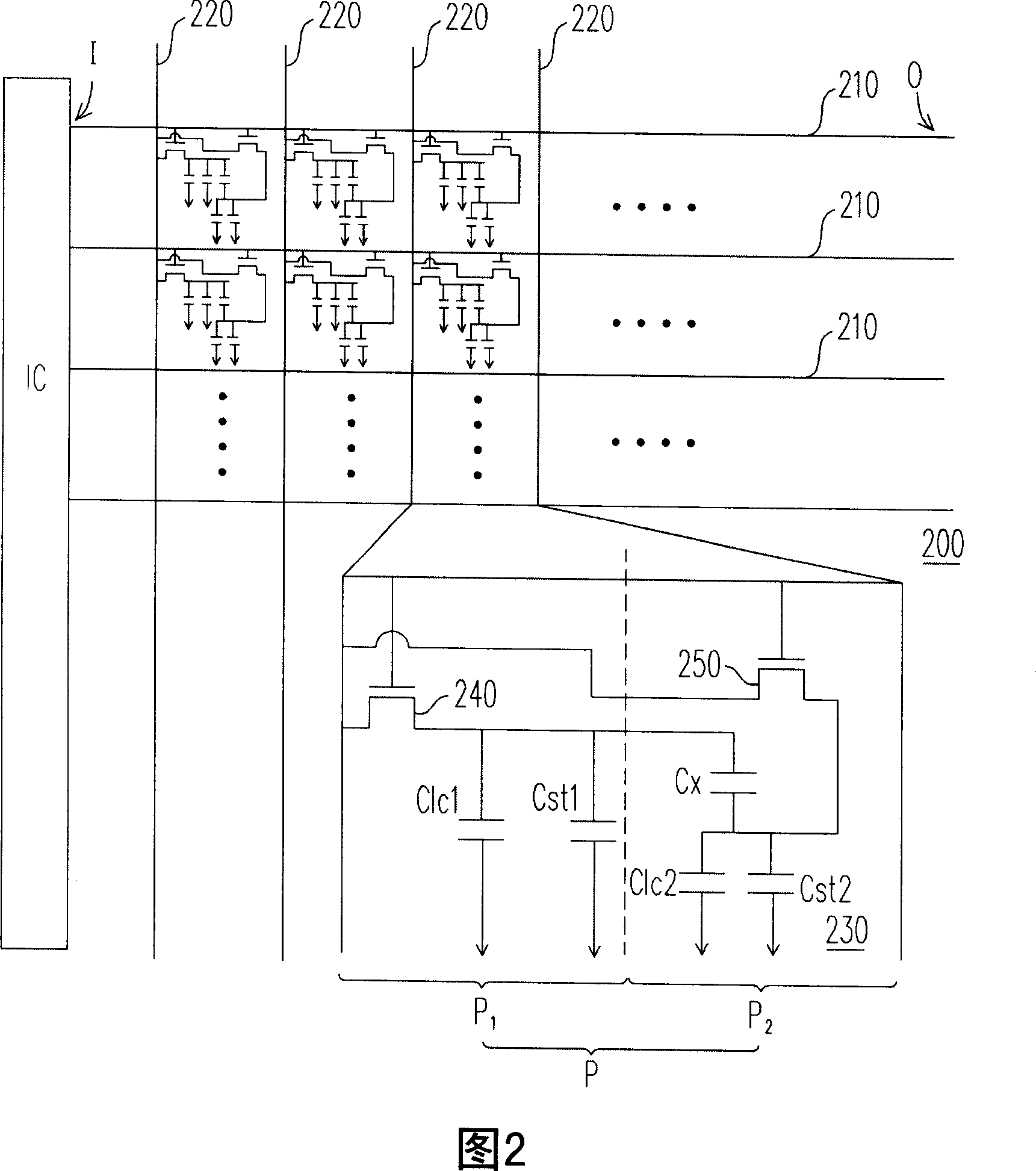

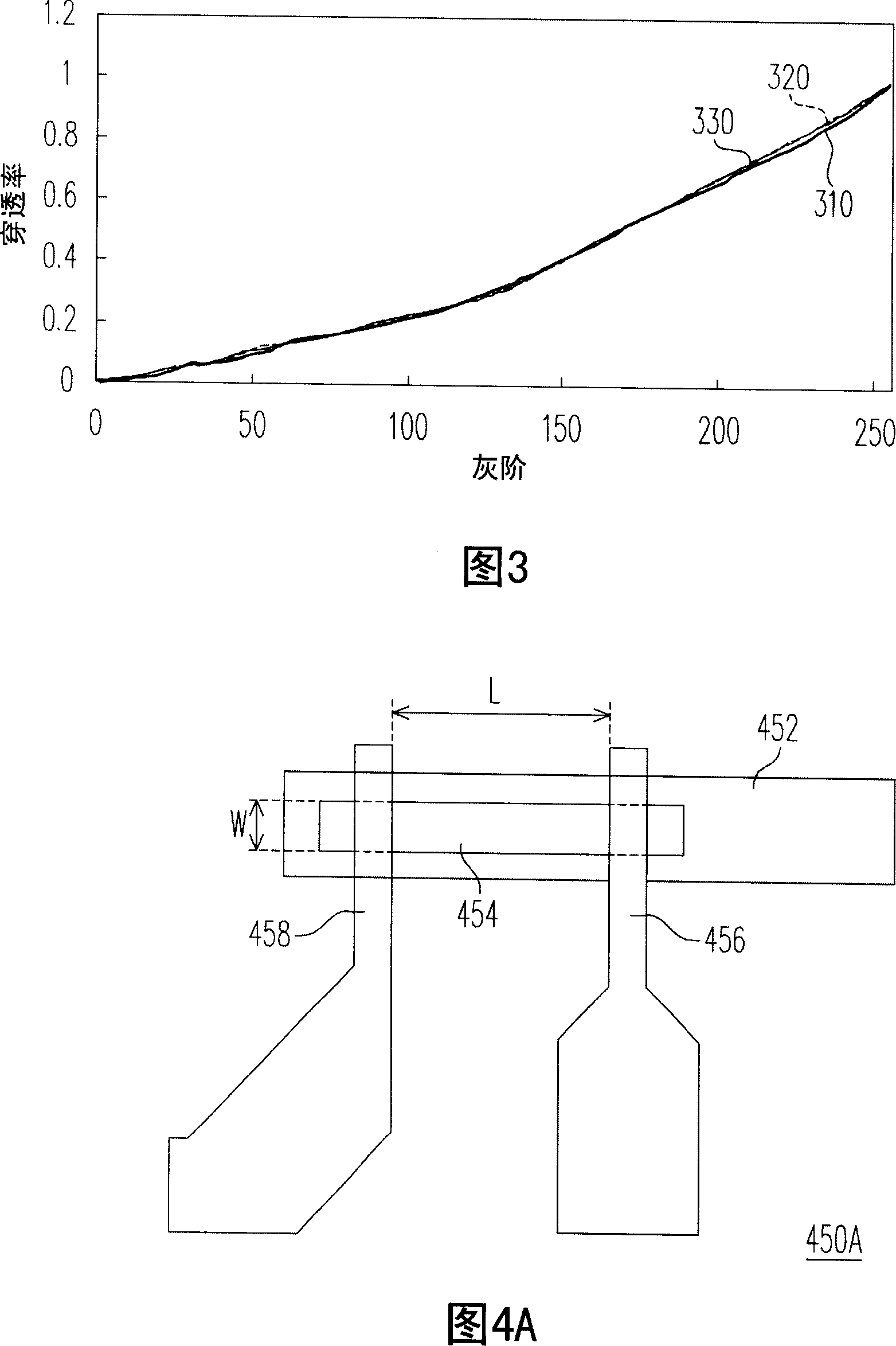

[0061] Generally speaking, in order to improve the resistance-capacitance hysteresis in the liquid crystal display panel, it is necessary to make each thin film transistor on the same scanning line in the thin film transistor array substrate have the same charge and discharge performance. Therefore, the present invention proposes a design of a thin film transistor array substrate. By changing the width and length of the channel layer in the thin film transistor, the thin film transistor far away from the input terminal of the driving signal has a larger W / L ratio, and the thin film transistor close to the input terminal of the driving signal has a larger W / L ratio. Transistors have a small W / L ratio. In this case, the charging and discharging performances of the thin film transistors on the same scan line can be approximately the same.

[0062] FIG. 2 is a schematic diagram of a thin film transistor array substrate according to a preferred embodiment of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com