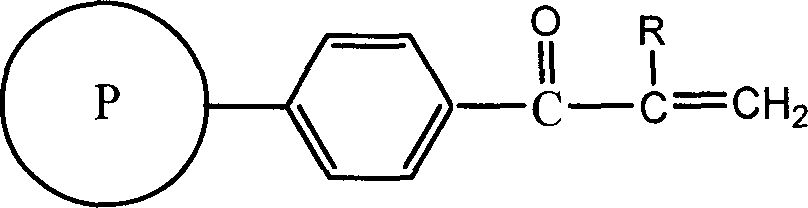

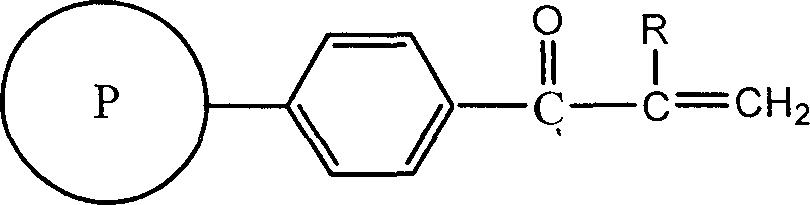

Polystyrene resin of containing double bond, and preparation method

A polystyrene resin and resin technology, applied in the field of functional polymers, can solve the problems of low double bond content and low cross-linking degree, and achieve the effects of simple reaction steps, high double bond content and high degree of substitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take 1g of polystyrene (cross-linking degree: 80% DVB, particle size: 5μm) into a three-neck reaction flask, add anhydrous dichloromethane to swell, stir to make it evenly dispersed, add 1ml of acryloyl chloride dropwise, blow in nitrogen, and stir 1.95 g of aluminum trichloride was added under the pressure, and the reaction was carried out at normal temperature and pressure for 4 hours. That is, a double bond-containing polystyrene resin having a double bond content of 0.93 mmol / g was obtained.

Embodiment 2

[0020] Take 1g of polystyrene (cross-linking degree: 7% DVB, particle size: 20μm) into a three-necked reaction flask, add anhydrous dichloroethane to swell, stir to make it evenly dispersed, add dropwise 1ml of acryloyl chloride, and blow in nitrogen, Add 0.64 g of aluminum trichloride under stirring, and react at room temperature and pressure for 1 hour. That is, a double bond-containing polystyrene styrene resin having a double bond content of 2.50 mmol / g was obtained.

Embodiment 3

[0022] Take 1g of polystyrene (cross-linking degree: 55% DVB, particle size: 20μm) into a three-necked reaction flask, add anhydrous nitrobenzene to swell, stir to make it evenly dispersed, add 1ml of acryloyl bromide dropwise, and blow in nitrogen. Add 0.3ml SnCl with stirring 4 , React at room temperature and pressure for 15 minutes. That is, a double bond-containing polystyrene resin having a double bond content of 2.17 mmol / g was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com