Method for making Nano microstructure based on constant height mode of atomic force microscope

An atomic force microscope and microstructure technology, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as limited size range, and achieve the effect of overcoming poor repeatability positioning accuracy, high repeatability positioning accuracy, and easy precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

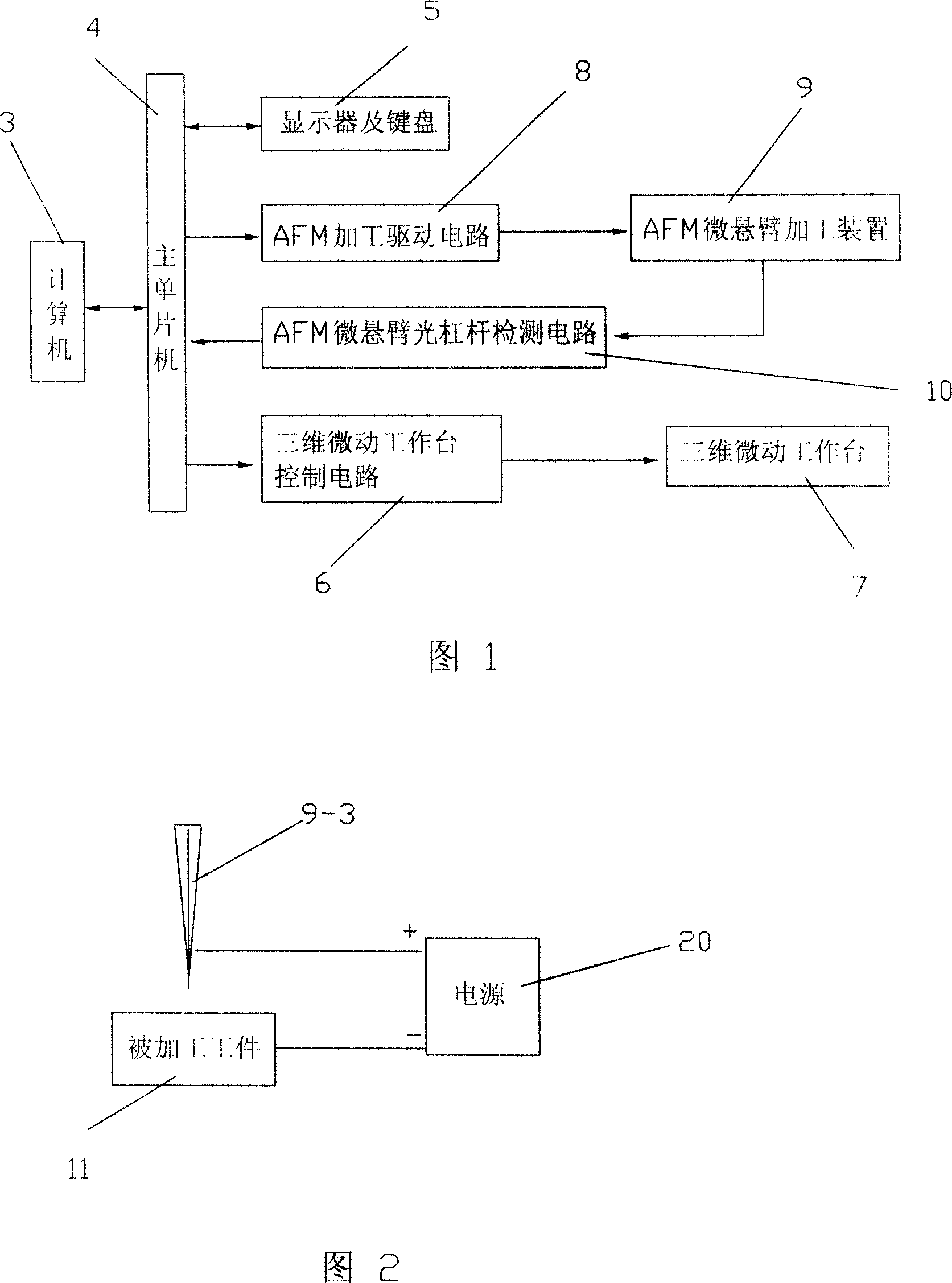

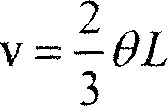

[0008] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 1 , FIG. 3 and FIG. 4 . The system of this method consists of a computer 3, a main single-chip microcomputer 4, a display and a keyboard 5, a three-dimensional micro-motion workbench control circuit 6, a three-dimensional micro-motion workbench 7, an AFM processing drive circuit 8, an AFM micro-cantilever processing system 9 and an AFM micro-cantilever light beam. Composed of lever detection circuit 10, AFM microcantilever processing system 9 includes scanning pottery tube 9-1, cantilever 9-2, probe 9-3 and optical lever angle measuring device 9-4, and the communication port of computer 3 is connected to one of main single chip microcomputer 4 Communication port, another communication port of main single-chip microcomputer 4 connects the communication port of display and keyboard 5, an output end of main single-chip microcomputer 4 connects the input end of AFM proce...

specific Embodiment approach 2

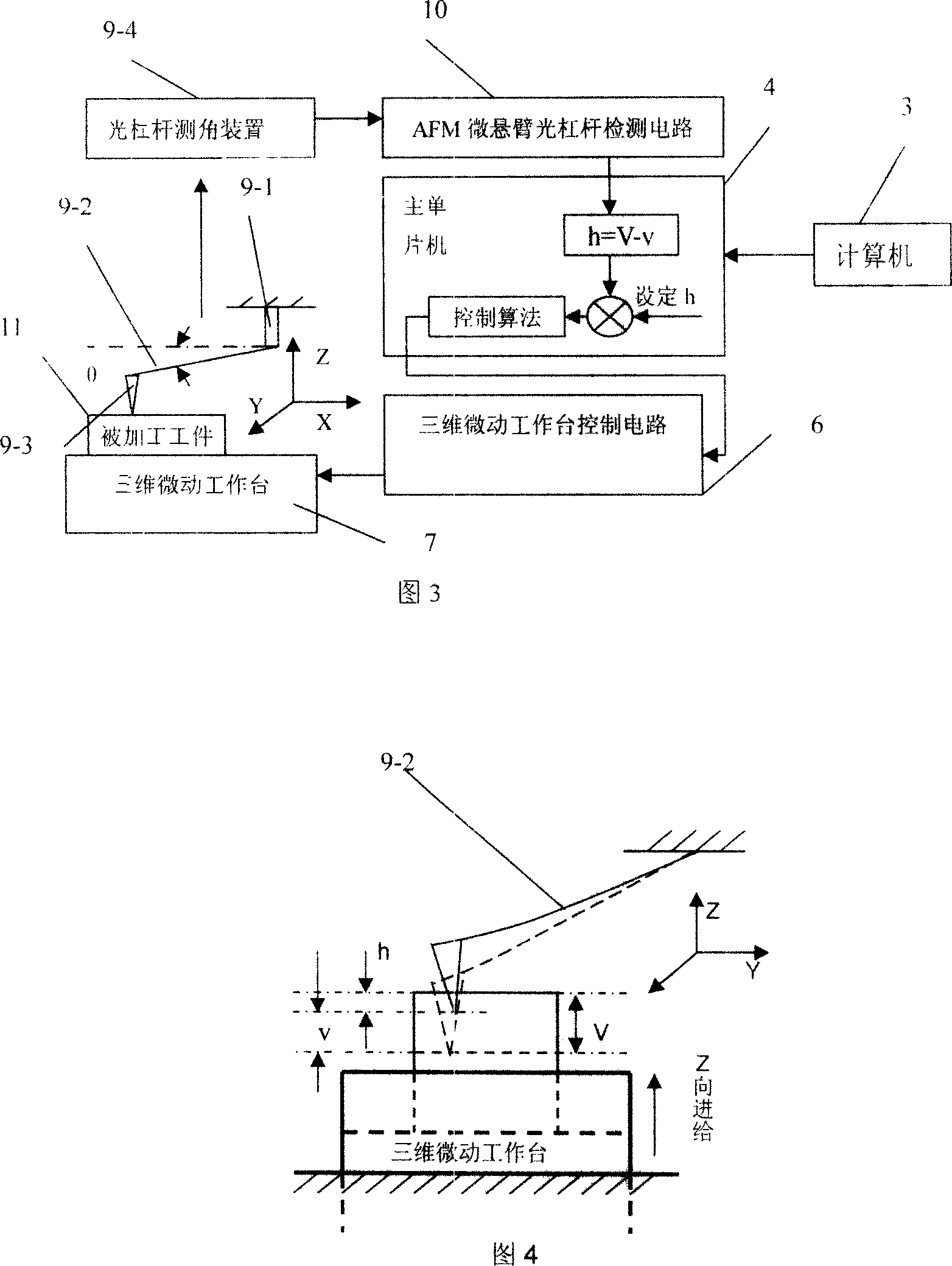

[0014] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 2 . The difference between this embodiment and Embodiment 1 is that its system also includes a power supply 20, the positive and negative poles of the power supply 20 are respectively connected to the probe 9-3 and the workpiece 11 to be processed, and the voltage amplitude of the power supply 20 is less than 10V, which is continuous The pulse time is 500ms. This function is another function added to the scoring function. The probe 9-3 and the workpiece 11 to be processed apply a voltage signal set by the user, and the voltage signal is independently isolated from other parts of the system, which can realize the needle-tip-induced local oxidation processing and needle-tip-induced local modification processing of the workpiece 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com