Application of turnary porous granule in cigarette production

A technology for porous particles and cigarettes is applied in the field of cigarette production to achieve the effects of reducing loss, good promotion prospects and lowering production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

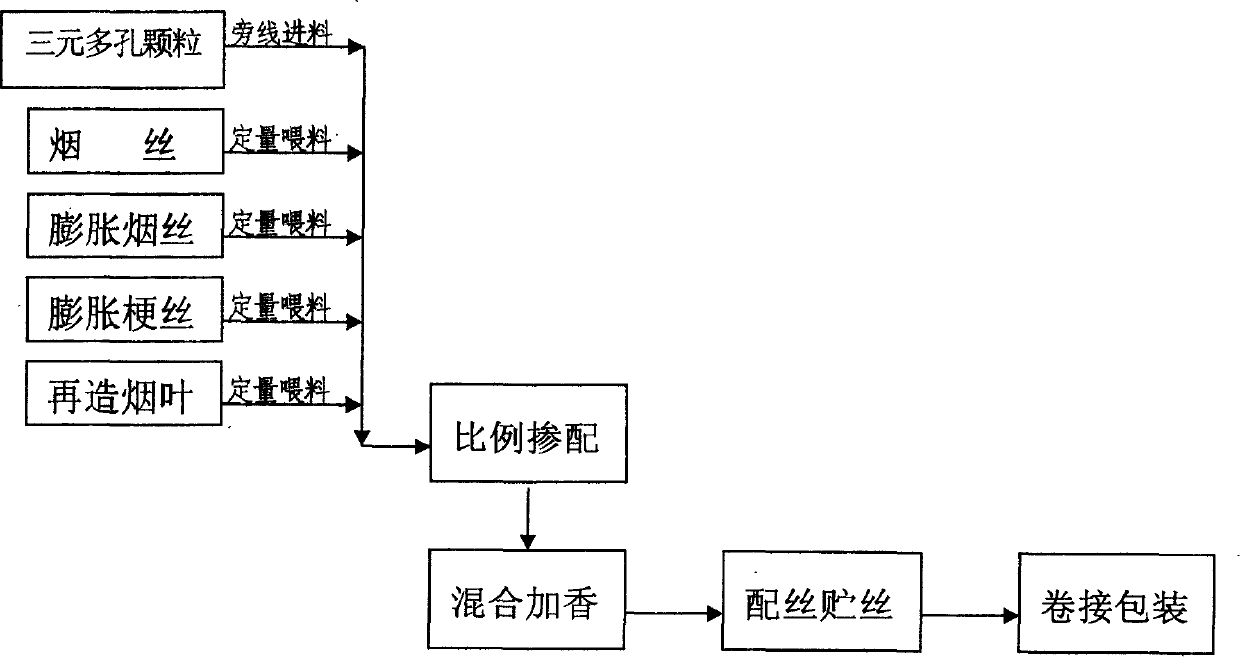

Method used

Image

Examples

Embodiment 1~4

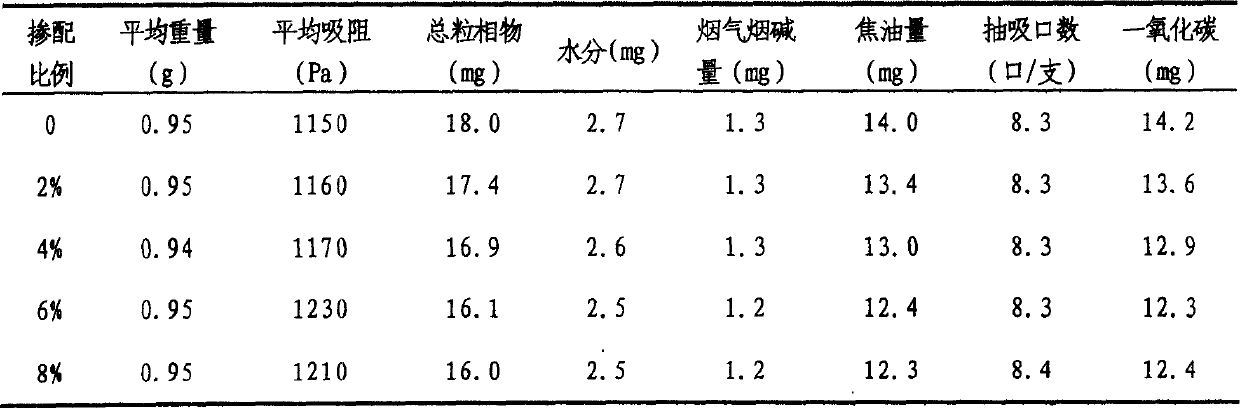

[0021] The conventional side-line feeding method uses a rake-type belt to convey materials. Due to the irregular shape of the ternary porous particles, it is easy to slip and fall during transportation, and cannot be effectively conveyed. Therefore, it is changed to a grooved belt for transportation. The ternary porous particles are evenly blended with shredded tobacco, the blending ratios are respectively 2%, 4%, 6% and 8%, and the blending accuracy is 1.0%. The blended formula silk is sent into the fragrance drum through the feeding vibrating groove. When the drum is running, the tooth nails on the inner wall of the drum drive the formula silk to roll and move forward. The essence in the essence barrel is powered by compressed air to form mist through the essence nozzle, and sprayed on the tumbling formula silk. The formula silk enters the storage room with temperature and humidity control, the set temperature is 28±2.0°C, the relative humidity is 65.0±5.0%, and the storage...

Embodiment 5~6

[0035] Example 1 was repeated, with the difference that: the blending proportions of the ternary porous particles accounted for 20% and 50% of the shredded tobacco respectively. The test results are shown in Table 3 and Table 4.

[0036] Table 3 Cigarette smoke detection table

[0037]

[0038]

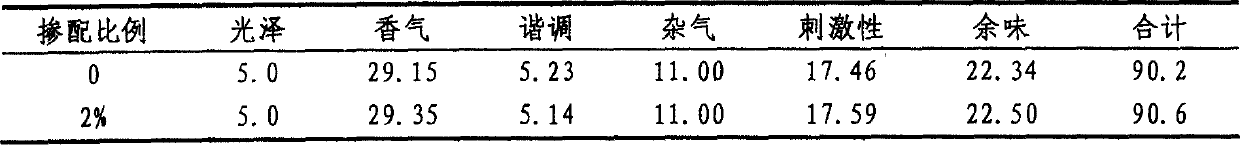

[0039] Table 4 Cigarette sensory quality evaluation table

[0040]

[0041] Analysis of test results:

[0042] Blending ratio 0: shredded tobacco is shiny and oily, the aroma is still sufficient, slightly rough, still harmonious, slightly miscellaneous, relatively irritating, slightly poor aftertaste, and slightly poor comfort.

[0043] Blending ratio of 20%: shredded tobacco is shiny and oily, the aroma is still sufficient, slightly rough, still harmonious, slightly miscellaneous, relatively irritating, and the aftertaste is still clean and comfortable.

[0044] Blending ratio of 50%: shredded tobacco is glossy and oily, the aroma is light, rough, still harmonious, with m...

Embodiment 7~8

[0047] Repeat Example 1, the difference is: the ternary porous particles are blended with shredded tobacco, expanded cut stems and expanded cut tobacco, the blending ratios of the expanded cut stems and expanded cut tobacco are both 6%, and the blending ratios of the ternary porous particles are respectively 6%, 10%, and the blending accuracy is 1.0%. The test results are shown in Table 5 and Table 6.

[0048] Table 5 Cigarette smoke detection table

[0049]

[0050] Table 6 Cigarette sensory quality evaluation table

[0051]

[0052] Analysis of test results:

[0053] Blended with 6% expanded cut stems and 6% expanded cut tobacco: shredded tobacco is shiny and oily, with sufficient aroma, slightly dull, more harmonious, no obvious miscellaneous smell, slightly irritating, slightly sharp on the palate, clean and comfortable aftertaste .

[0054] Blended with 6% expanded shredded stem, 6% expanded shredded tobacco, and 6% ternary porous particles: the shredded tobacco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com