Process for comprehensive utilization of plant discarded matter

A plant waste and plant charcoal technology, applied in the field of comprehensive utilization of plant waste, can solve the problems of environmental pollution and low utilization value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

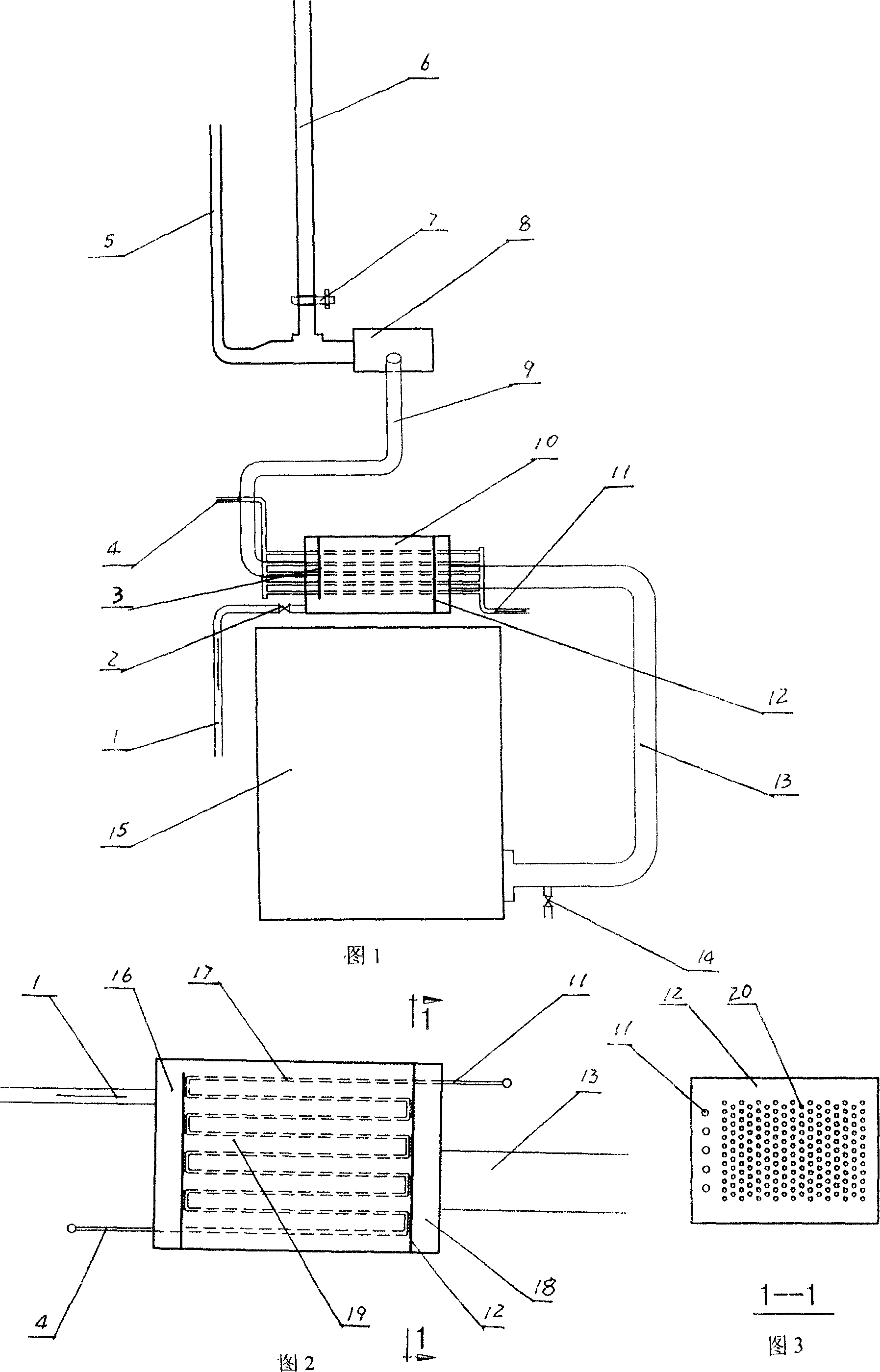

[0025] Build a brick carbonization furnace or a mechanical carbonization furnace according to the design requirements, lead out the primary smoke outlet pipe (13) on the charcoal kiln (15), set a tar discharge pipe (14) at the lower part of the primary smoke outlet pipe, and introduce the condensation gas into the primary smoke outlet pipe The condenser (10), the condenser is a closed box with one end connected to the primary smoke outlet pipe (13), and the other end connected to the secondary smoke outlet pipe (9). The front end of the condenser cavity is covered with smoke holes ( The smoke distribution plate (12) of 20) separates the inner cavity of the box into a smoke buffer bin (18), a condensation bin (19) and a vegetable vinegar storage bin (16), and a circulating condensate pipe (17) is arranged in the condensation bin (19) ), the cooling water inlet (4) is located at the left end, and the cooling water outlet (11) is located at the right end. Spiral around. A suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com