Bimetallic cyanide catalyst for epoxide ring-opening polymerization

A double metal cyanide, ring-opening polymerization technology, applied in the field of double metal cyanide complex catalyst, can solve the problems such as the performance of DMC catalyst needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] System cat: Zn 3 [Co(CN) 6 ] 2 ·ZnCl 2 0.4H 2 O 0.18TBA 0.055L 1 0.055L 2

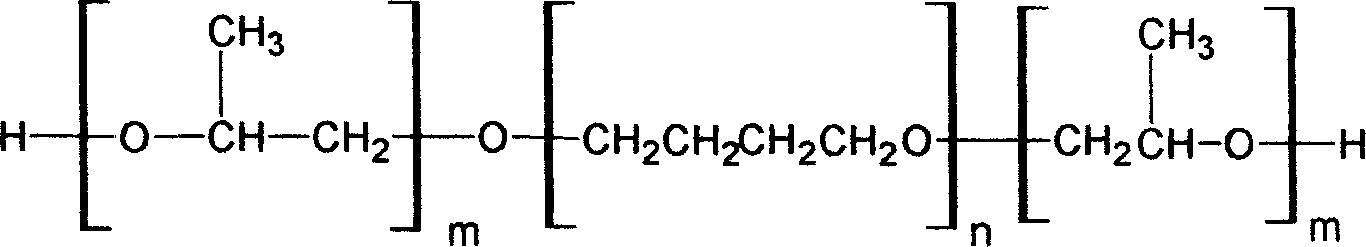

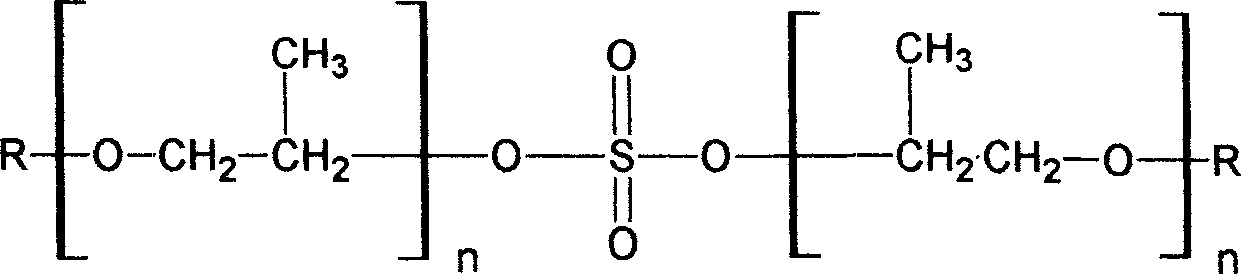

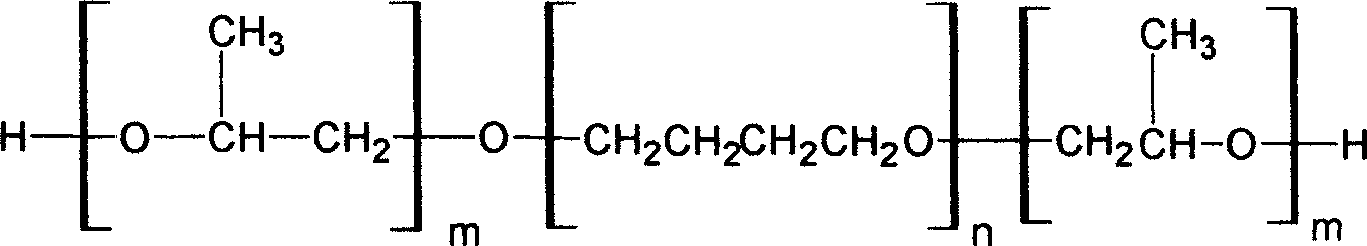

[0049] 120g ZnCl in a container 2 Dissolve in 250ml TBA / 450ml deionized water, in another container, 30g K 3 [Co(CN) 6 ] dissolved in 450ml of deionized water, fully mixed for solid-liquid separation to obtain DMC paste, washed with about 50% TBA aqueous solution 1000ml, that is, the process of solid-liquid separation after fully mixing to form a slurry, this washing process is carried out Three times, and finally washed once with 1000ml pure TBA to replace the water in DMC. The separated paste was added with 6g polytetrahydrofuran propylene oxide block polyether (M n =2500, by molecular weight is 1000 polytetrahydrofuran propoxylated to the target molecular weight) and 6g polyether sulfate (M n =2000, the structure is: dodecyl alcohol is initially propoxylated to a molecular weight of about 1000, and sulfuric acid is used to diesterize), then add 500-1000ml and mix well, press filter...

Embodiment 2

[0088] Catalyst performance comparison when the polytetrahydrofuran propoxyethylene block polyether used in the present invention has different molecular weights (the sulfuric acid polyether ester used remains unchanged).

[0089] With embodiment 1 processing step, used L 1 Structure is similar, molecular weight is different, with prepared catalyst by example A system polyoxypropylene glycol (M n =4000) the result is as follows:

Embodiment 3

[0091] Catalyst performance comparison during different structures of polyethersulfate polyether ester in the present invention (used polytetrahydrofuran propoxypropylene block polyether is the same as embodiment 1)

[0092] With embodiment 1 processing step, used L 2 The polyether part has different structures, and the polyoxypropylene dibasic alcohol (M n =4000) the result is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com