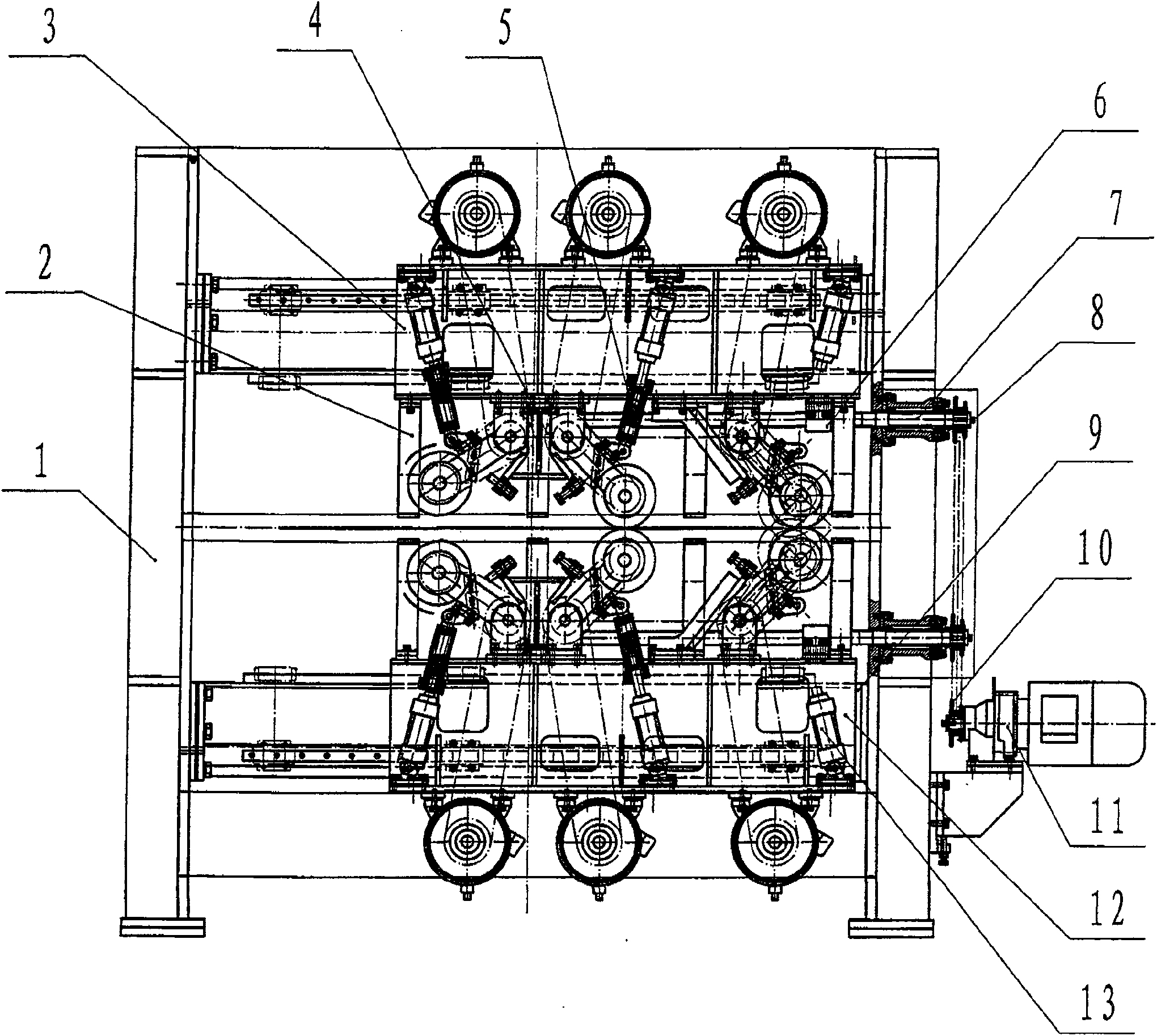

Novel rust cleaning machine

A rust remover, a new type of technology, is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc. It can solve the problems of ineffective removal of double-sided rust removal and dust pollution of the strip, and achieves manpower saving and high automation level. , Processing and manufacturing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

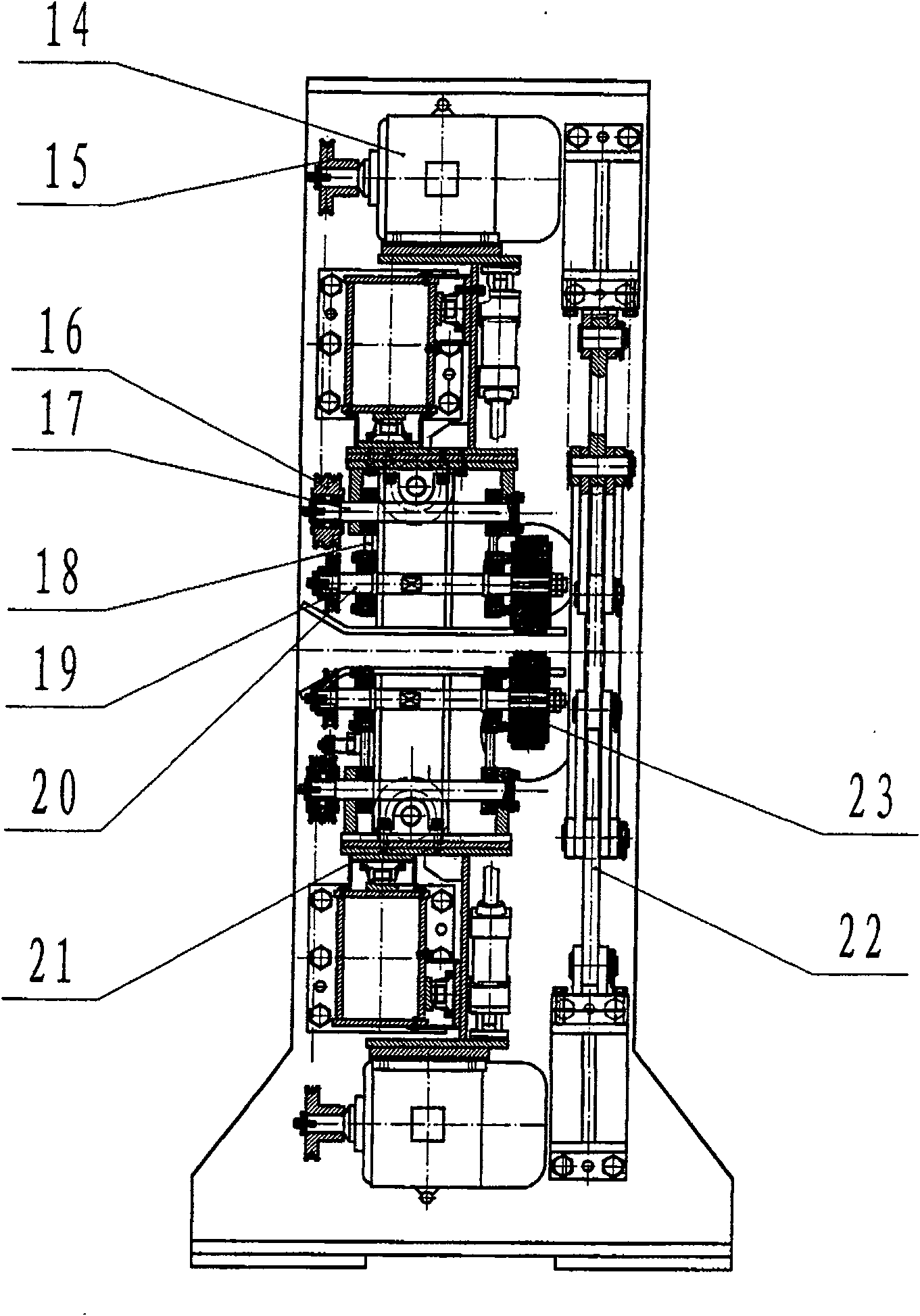

[0014] The synchronous motor 11 can rotate in the forward and reverse directions, and the driven sprocket 8 drives the screw nut 6 to rotate. The two sets of screw nuts 6 are fixed on the upper door frame 3 and the lower door frame 12 respectively. Drive the screw nut 6 to rotate, so that the upper door frame 3 and the lower door frame 12 move synchronously along the horizontal beam 9 through the linear guide rail, so as to ensure that the upper and lower brush wheels are always in contact with the same point during the movement process, and can fully contact with the steel plate to adapt to the steel plate. The deformation of the surface can completely remove the iron oxide scale on the surface of the steel plate. By adjusting the rotating speed of the synchronous motor 11, through the sprocket pair, the lead screw and the female pair obtain different synchronous moving speeds of the upper door frame 3 and the lower door frame 12, that is, the lateral moving speed of the multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com