Fork type controlled non-contact wedge backstop

A non-contact and backstop technology, applied in the direction of brake types, conveyor control devices, conveyor objects, etc., can solve the problems of uneven distribution of positioning pins and stop pins, strict assembly process requirements, and inconvenient serial processing. Achieve the effect of easy assembly, uniform load distribution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

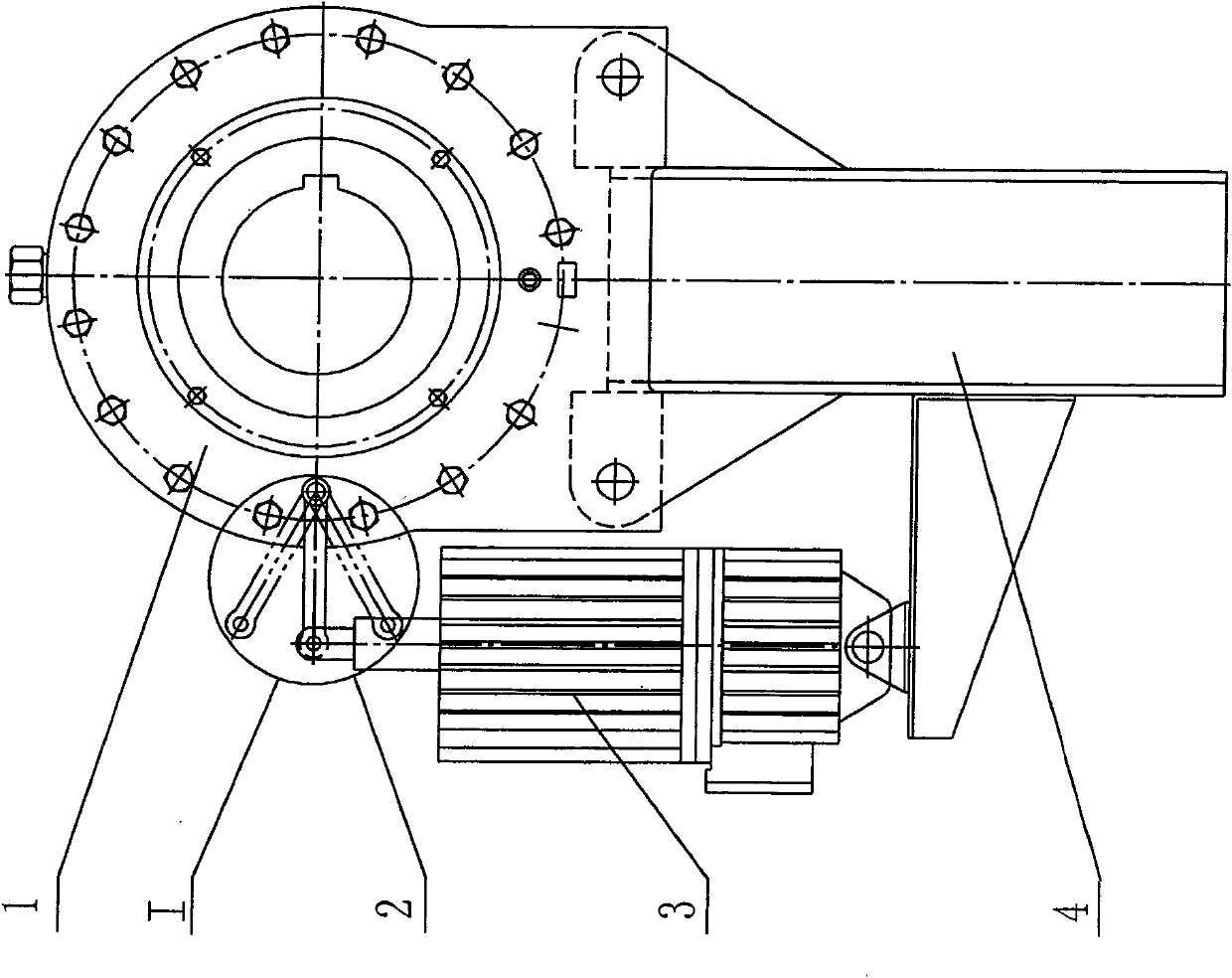

[0033] refer to figure 1 , figure 2 As shown, a fork-type controllable non-contact wedge backstop is mainly composed of a backstop part 1, a fork part 2, a controller 3, an anti-rotation arm 4, a wedge assembly 5 and other components; The backstop part 1 is installed on the top surface of the anti-rotation arm 4, the controller 3 is installed on the anti-rotation arm 4, and is connected in series with the host machine of conveying equipment such as belt conveyor or bucket elevator, and the fork part 2 is connected with the backstop Component 1 and controller 3 are connected, and controller 3 is prior art, and any one of electromagnetic mechanism, electric hydraulic pusher, pneumatic or hydraulic pusher, etc. can be used.

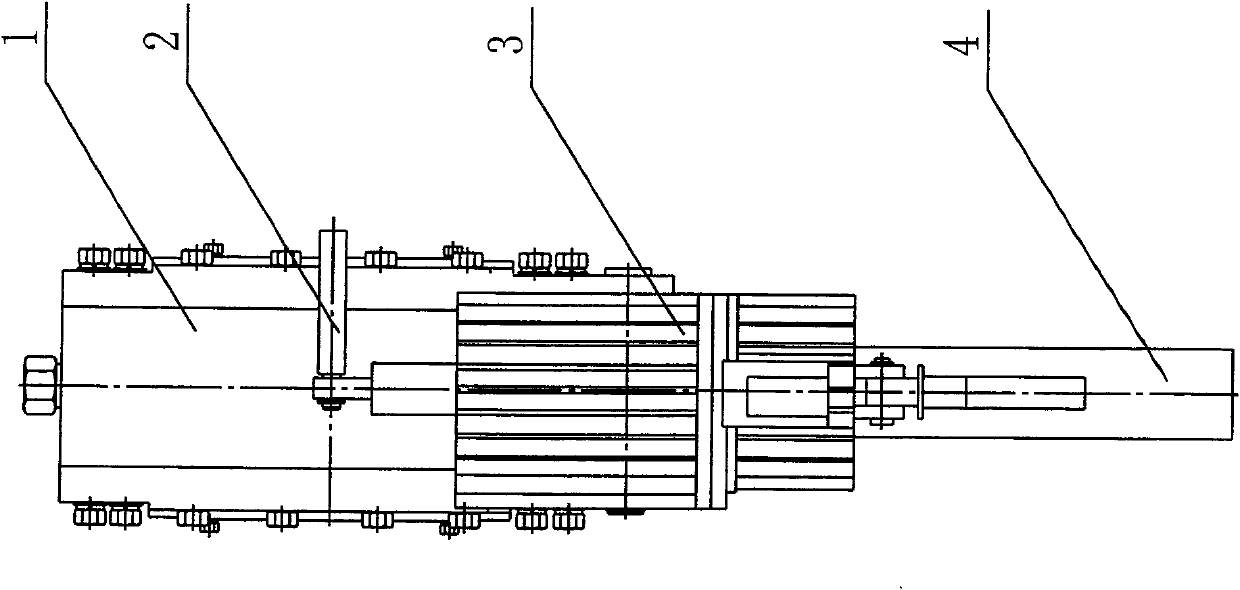

[0034] see also image 3 , Figure 4 As shown, the backstop component 1 includes parts such as outer ring 101, inner ring 102, sealing ring 103, bearing 104, end cover 105, cover plate 106; the inner ring 102 of the backstop component 1 is installed on t...

Embodiment 2

[0038] refer to Figure 9 , Figure 10 As shown, the shift fork part 2 can also protrude from the long hole on the end face of the end cover 105 of the backstop part 1 to connect with the controller 3 .

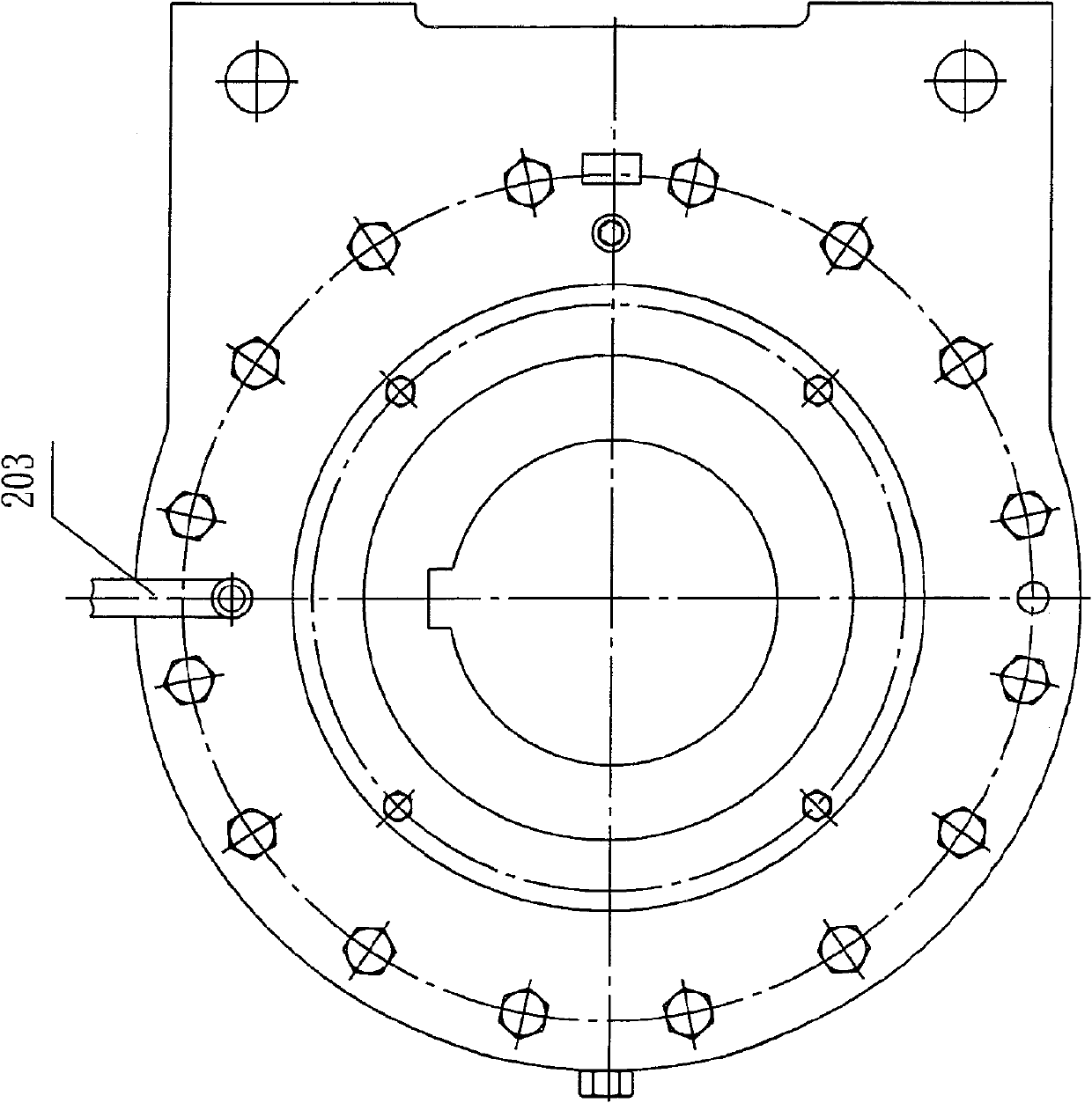

[0039] refer to Figure 11 , Figure 12 , Figure 13 As shown, the inner end fork of the shift fork 204 of the shift fork part 2 is clamped on any shift ring positioning pin 506 of the shift ring 501, and the outer end is from the end cover 105 of the backstop part 1, which can be the front end cover Or protrude from the long hole provided on the end face of the rear end cover, adopt packing or hair sticky seal, and connect the connecting rod 203 through bolts, and the connecting rod 203 is connected with the controller 3 . All the other structures of embodiment 2 are the same as embodiment 1.

Embodiment 3

[0041] refer to Figure 14 , Figure 15 As shown, the shift fork part 2 can also protrude from the circumference of the end cover 105 of the backstop part 1 to connect with the controller 3 .

[0042] refer to Figure 16 , Figure 17 , Figure 18 As shown, the shift fork shaft 201 is arranged in the end cover 105, and the outer end of the shift fork shaft 201 is provided with a connecting rod 203, and the connecting rod 203 can be a front end cover or a rear end The circular hole on the circumference of the cover protrudes to connect with the controller 3. The inner end of the shift fork shaft 201 is movably connected to the outer end of the shift fork 204. Ring positioning pin 506. All the other structures of embodiment 3 are the same as embodiment 1.

[0043] Working principle of the present invention:

[0044]When the main unit of the equipment is powered on, the controller 3 connected in series with the main unit power supply is also started at the same time, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com