Power socket and bush

A power socket and socket technology, which is applied to circuits, electrical components, two-component connection devices, etc., can solve the problems of loss, unreasonable socket structure, poor contact, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

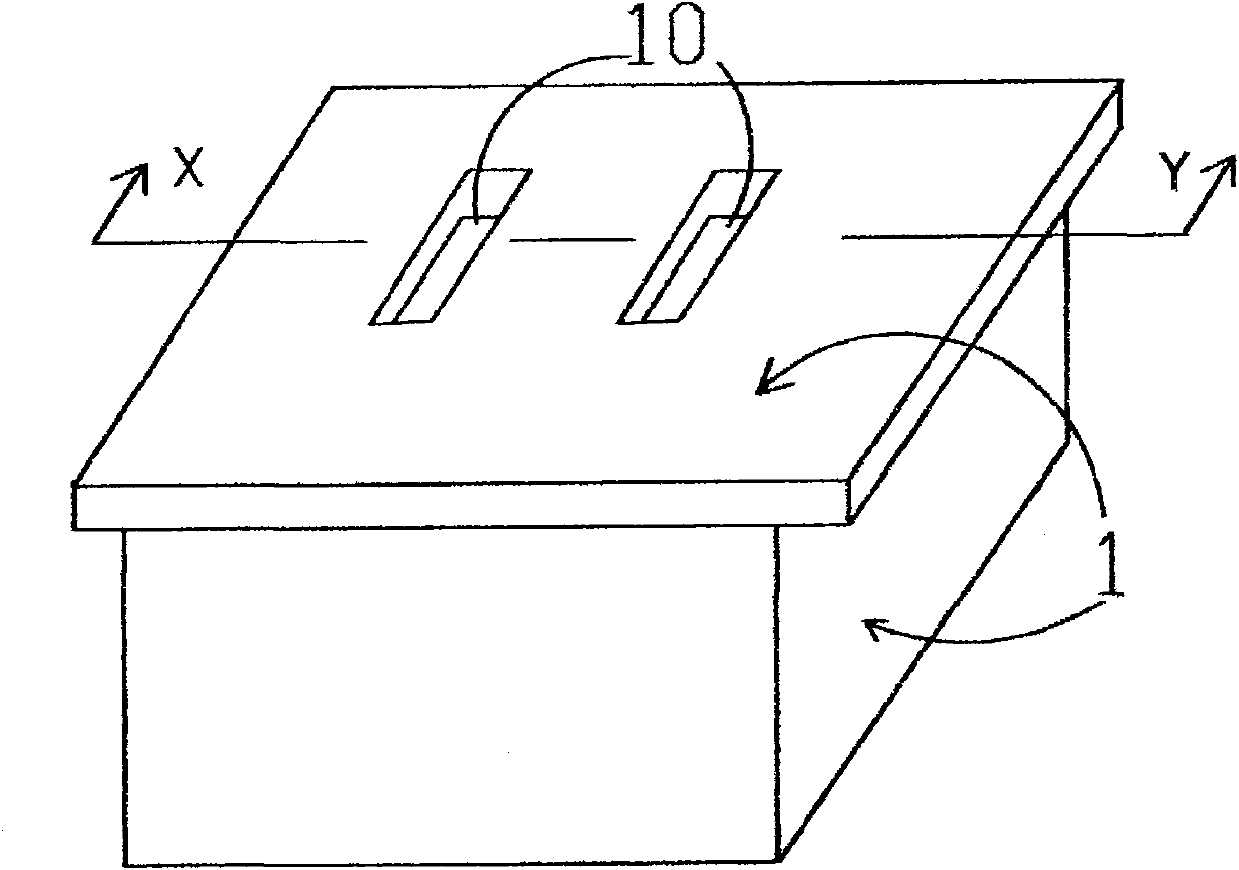

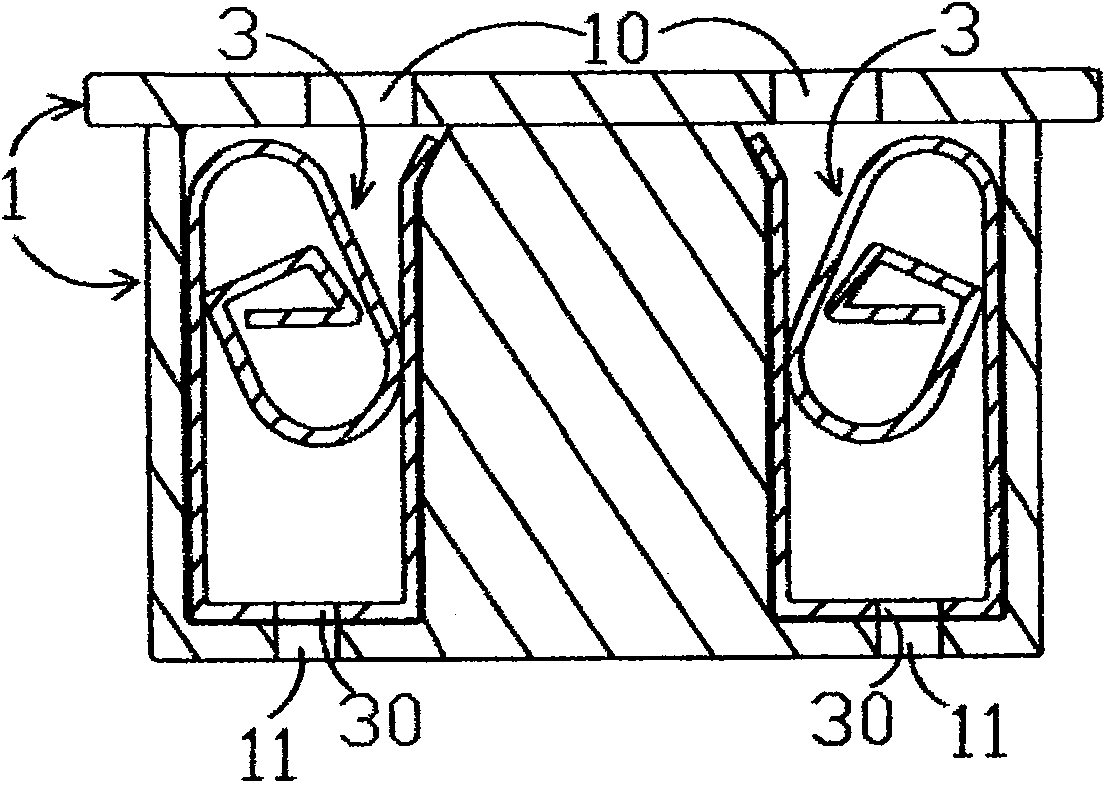

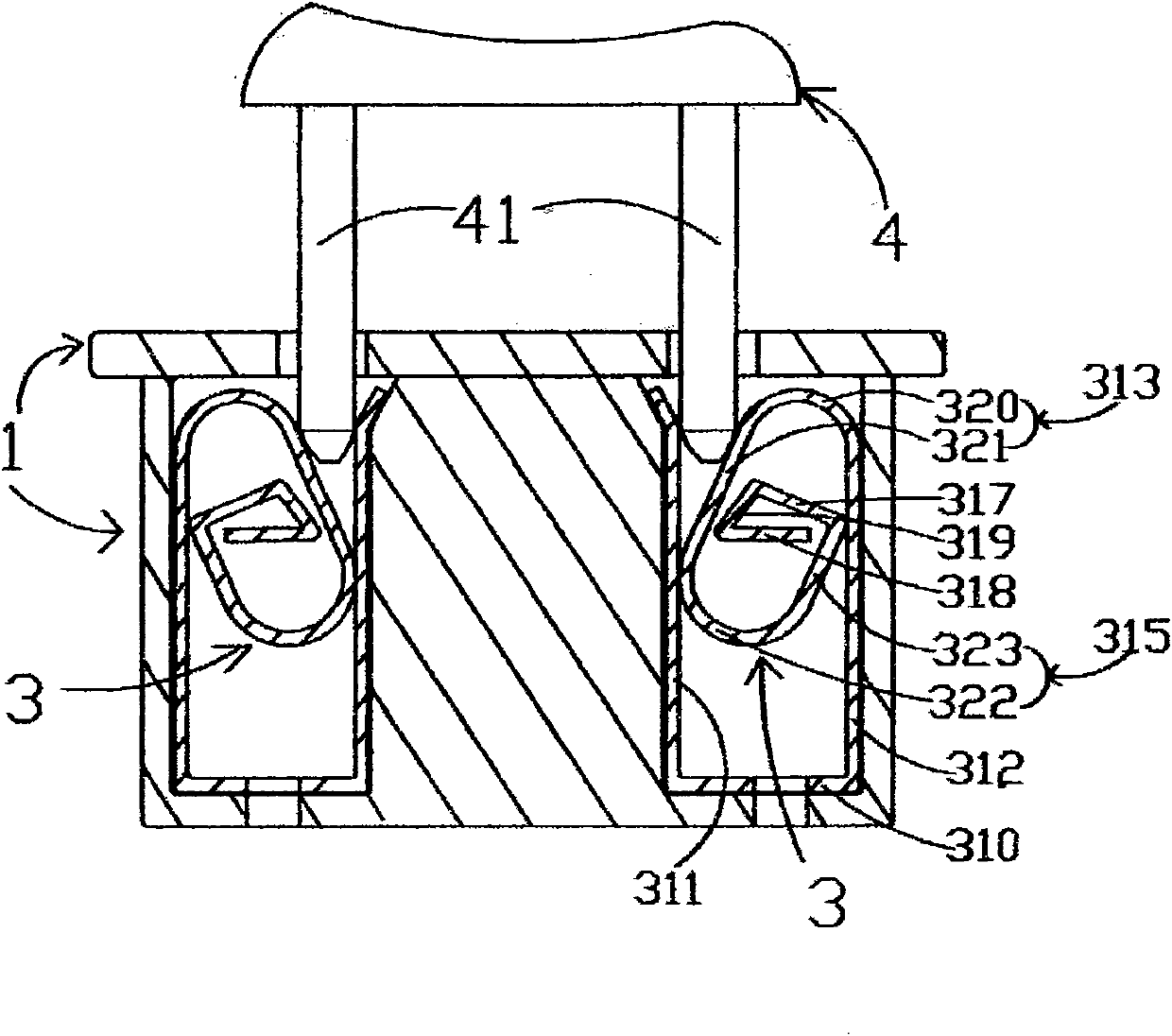

[0019] figure 1 It is a side perspective schematic diagram of an embodiment in which the power socket of the present invention is installed, figure 2 yes figure 1 X-Y cross-sectional view. Power socket is made up of insulating shell 1 and conductive socket 3, has jack 10 and the threading hole 11 of external power supply on insulating shell 1, has the wiring hole 30 of external power supply at the bottom wall 310 of conductive socket 3.

[0020] Such as Figure 5 As shown, the sleeve 3 is made by continuous bending of a strip of elastic metal sheet. The curved portion 320 and the contact piece 321 constitute the elastic contact piece 313; the contact piece 321 bends and extends toward the inner direction of the groove wall 312 to form an arc-shaped curved portion 322 and a support piece 323, which constitutes an elastic support Sheet 315; the support sheet 323 bends toward the contact sheet 321 side and extends a support arm 317 perpendicular to itself; the support arm 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com