Oblique flange hole technology of mould punching

A technology of hole turning and process, which is applied in the field of die stamping technology, can solve problems such as the size of the flanging bottom hole, the cracking of the turning hole, etc., so as to improve work efficiency, solve the problems of the size of the flanging bottom hole and the cracking of the turning hole, and save repetition Effect of tryout correction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

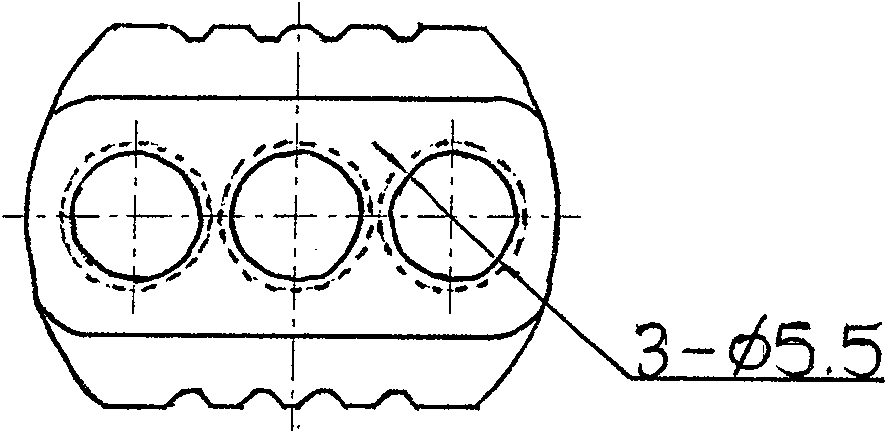

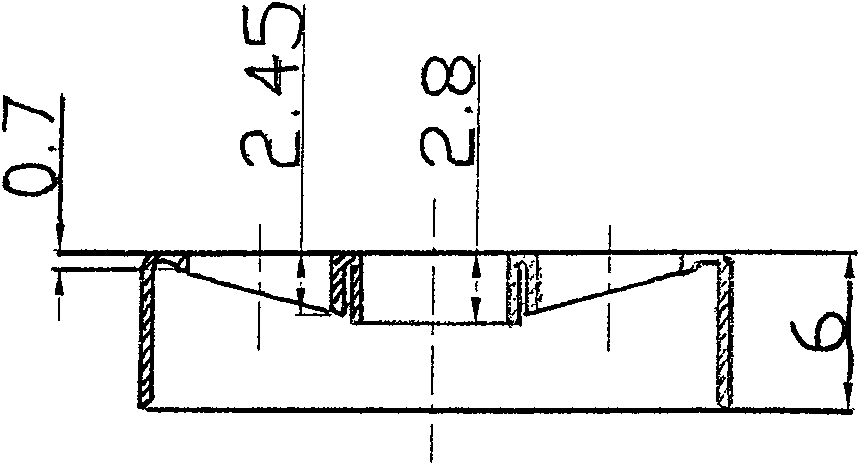

[0020] Embodiment 1: Referring to Fig. 1, the two side holes 1 of the electron gun are inclined planes, and the following two items must be designed to stamp this product:

[0021] 1. Calculation of the pre-punched bottom hole of the inclined hole:

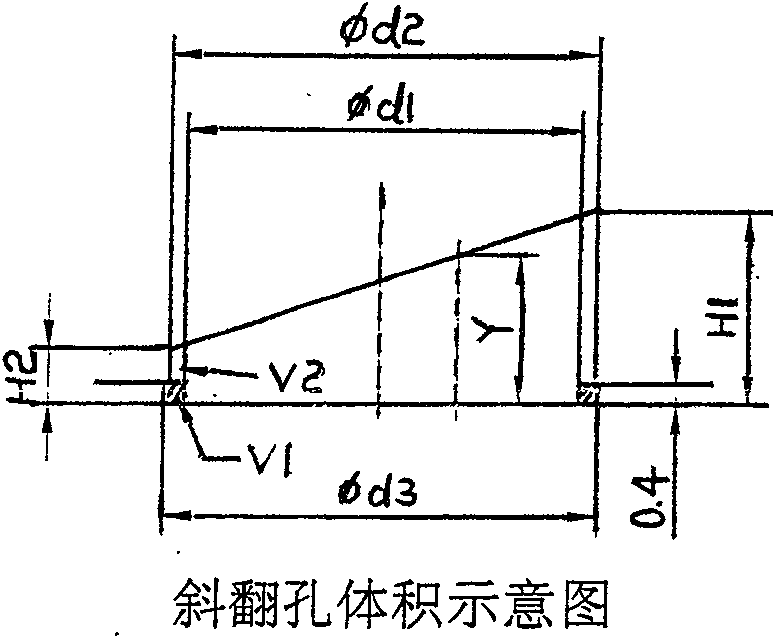

[0022] Expand the side hole 1 on the horizontal plane, according to the principle that the height of each point relative to the center of the circle is constant according to the volume, calculate the distance from the horizontal plane to the center of the circle by V0=V, connect all the calculated distance points, this is the bottom hole curve shape (see figure 2);

[0023] V0=volume after flanging=edge volume V1+side hole volume V2

[0024] V = expanded volume

[0025] Because: V=(π / 4)×(d3 2 -d0 2 )×t

[0026] so: d 0 = d 3 2 - 4 × V / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com