Extremely low acidity USY and homogeneous, amorphous silica-alumina hydrocracking catalyst and process

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems affecting catalytic selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1 : USY zeolite

[0074] The properties of acceptable USY zeolites are shown in the table below:

[0075] Table 1

[0076] Physical properties of highly dealuminated USY

[0077] Compliant USY#1

Qualified USY#2

SiO 2 / Al 2 o 3 The molar ratio of

Na 2 O, wt%

surface area, m 2 / g

Micropore volume, cc / g

Total pore volume, cc / g

Unit cell size, Angstroms

alpha

Bronsted acidity measured by FT-IR, μmol / g

88

<0.05

686

0.25

0.51

24.24

-

1.1

9

126

0.1

690

0.27

0.54

24.25

99

1.4

15

[0078] Acceptable USY zeolites are bulk SiO 2 / Al 2 o 3 Highly dealuminated and stable with a ratio higher than 80. The unit cell size measured by powder X-ray diffraction showed a unit cell size of 24.25 Angstroms or less. In addition, we found that USY with very low Bronsted acidity is import...

Embodiment 2

[0080] Example 2 : Uniform cogel silica-alumina

[0081] The following three homogeneous cogel silica-alumina samples were used to prepare the catalysts. The silica-alumina body has a Si / Al atomic ratio of about 1.0. The composition is homogeneous in that the surface Si / Al ratio measured by XPS matches the bulk composition, with less than 10% by weight of a separate crystalline alumina phase detected by XRD. The properties of this homogeneous cogel silica-alumina are shown in the table below:

[0082] Table 2

[0083] Physical properties of homogeneous cogel silica-alumina

[0084]

[0085] (a): BET measurement after activation at 1000°F for 1 hour.

[0086] (b): Measured after activation at 1000°F for 1 hour.

Embodiment 3

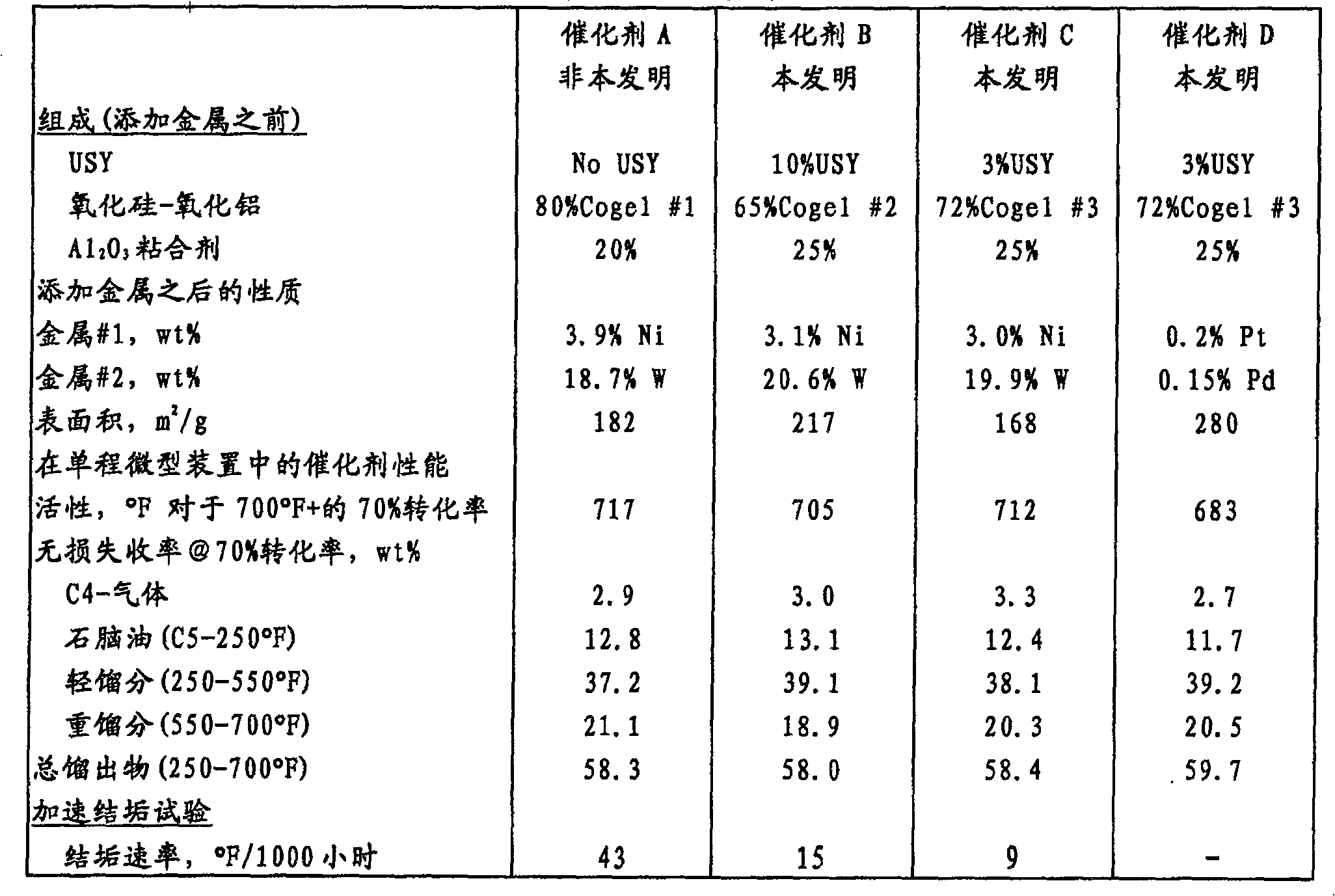

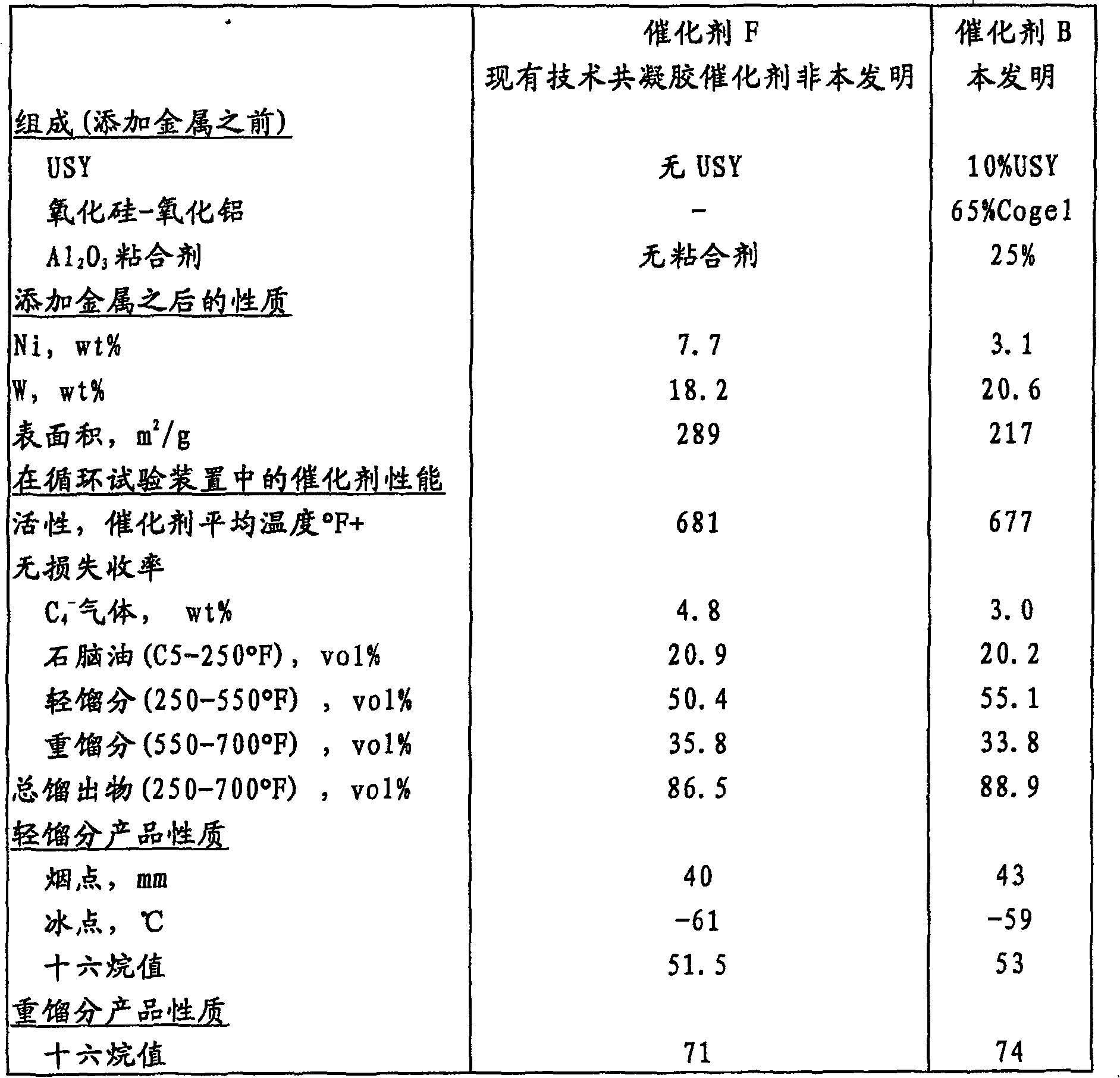

[0087] Example 3 : Preparation of NiW Hydrocracking Catalyst with Homogeneous Cogel Silica-Alumina (Catalyst A - Base Case)

[0088] A base case hydrocracking catalyst comprising homogeneous silica-alumina sample #1 in Table 2 was prepared as follows. 75 parts of silica-alumina powder #1 (synthesized according to patent application XXXX) and 25 parts of crystalline alumina powder (from Vista) were thoroughly mixed. To this mixture was added dilute HNO 3 acid and sufficient deionized water to form an extrudable paste (3 wt% HNO 3 ). These weights are based on 100% solids. The paste was extruded in a 1 / 16" cylinder and dried overnight at 250°F. The dried extrudate was fired at 1100°F for 1 hour with excess dry air blown in and cooled to room temperature.

[0089] Ni and W were impregnated with a solution containing ammonium metatungstate and nickel nitrate to a target metal loading of 4 wt% NiO and 28 wt% WO in the finished catalyst 3 . The total volume of the solution w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| unit cell dimension | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| unit cell dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com