Plasticity forming numerical value emulation method

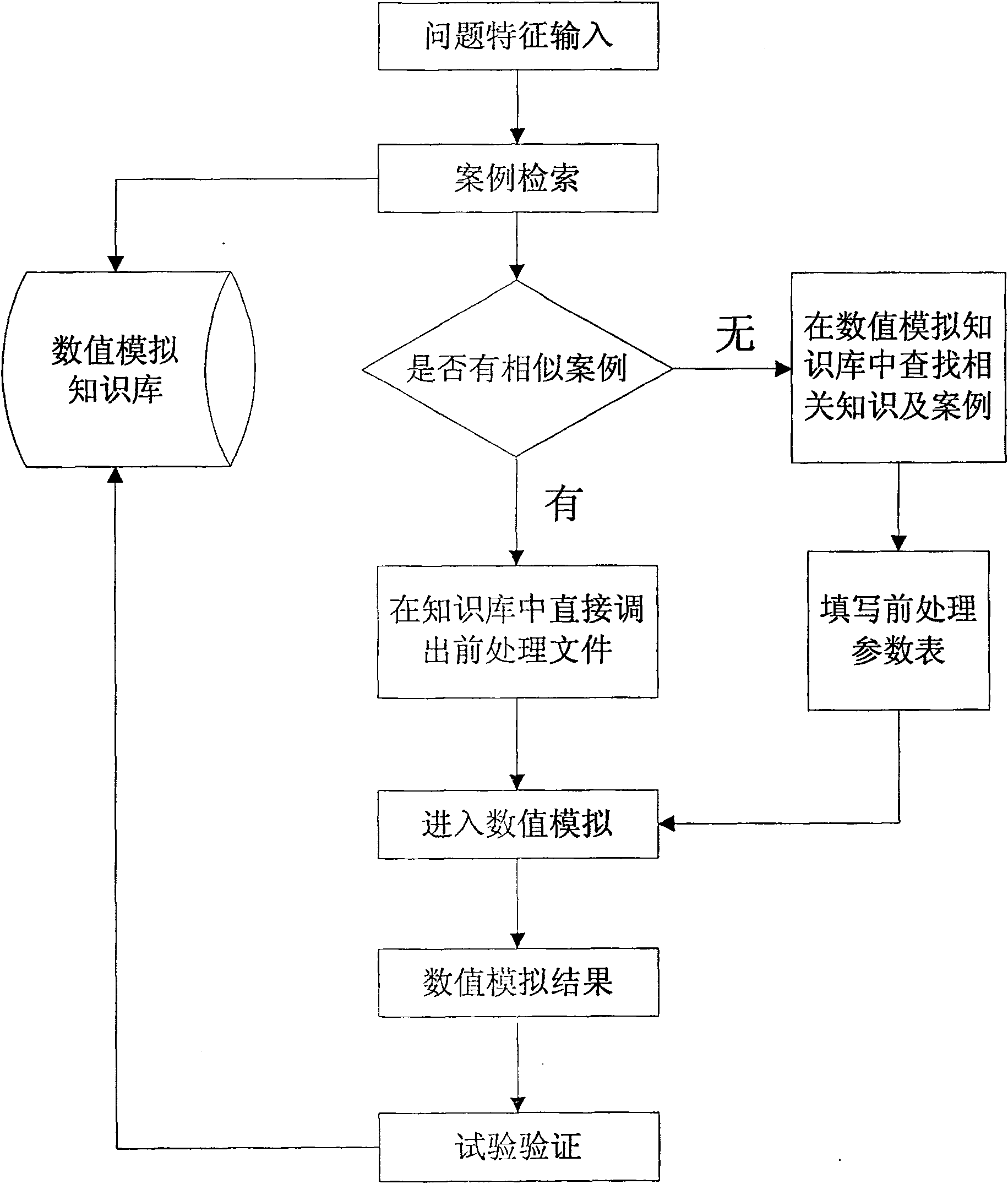

A numerical simulation and plastic forming technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of incomplete basic software parameters, shorten simulation time, low simulation accuracy, etc., to improve the level of numerical simulation, promote The effect of promoting application and reducing technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

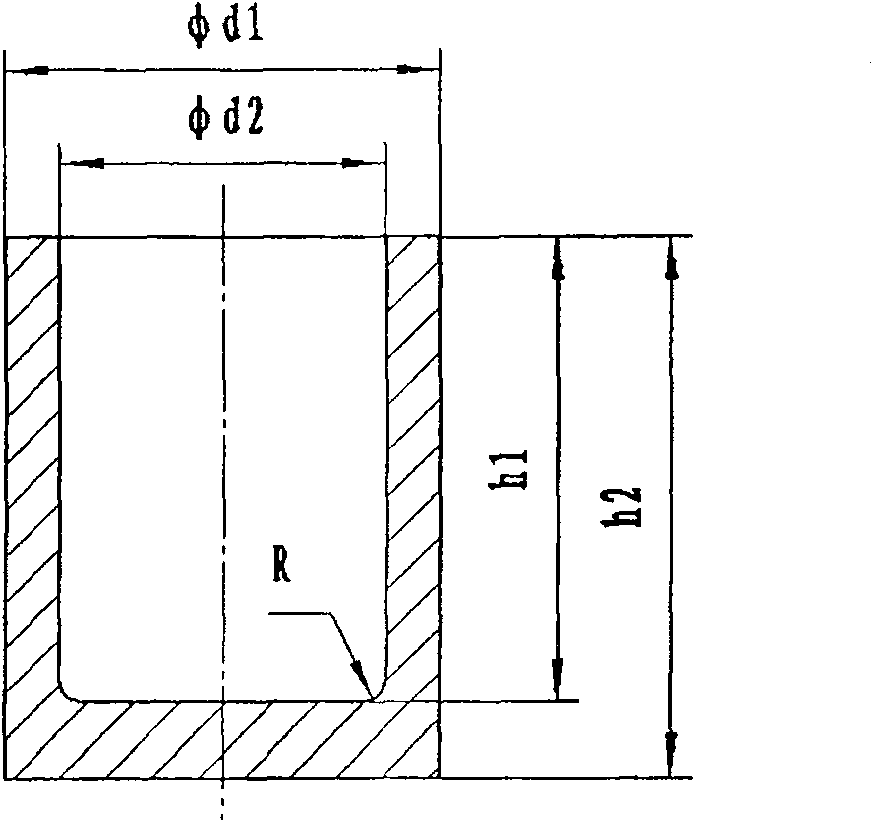

[0021] Back extrusion is a typical plastic processing technology. The present invention takes figure 2 The piston extrusion shown is an example. The material is 20Cr, and the dimensions are: Φd 1 =40mm, Φd 2 = 30mm, h 1 = 43mm, h 2 = 50mm, R = 2mm.

[0022] When extruding, the cylindrical blank is formed at room temperature through the reverse extrusion process. The mold mainly includes a punch and a die. Simulation software adopts U.S. DEFORM software, and concrete steps of the present invention are as follows:

[0023] 1. Numerical simulation case retrieval

[0024] Based on the clues of part shape features - cylinder shape, size features, material features - 20Cr, process features - cold extrusion, reverse extrusion, in the numerical simulation knowledge base of the knowledge-based plastic forming numerical simulation module Retrieve, retrieve whether there are similar numerical simulation cases.

[0025] 2. Pre-processing parameter input

[0026] After searchin...

Embodiment 2

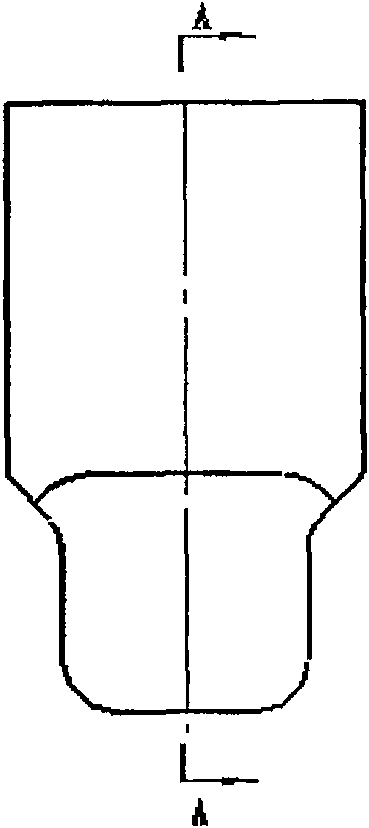

[0043] The piston extrusion shown in Figure 3 is a special-shaped piston, and the material is 20CrMn. When extruding, the cylindrical blank is formed at room temperature through a composite cold extrusion process. The mold mainly includes two punches and a die. Simulation software adopts U.S. DEFORM software, and concrete steps of the present invention are as follows:

[0044] 1. Numerical simulation case retrieval

[0045] Search in the numerical simulation knowledge base in the knowledge-based plastic forming numerical simulation module with the clues of part shape features - cylindrical, fork, material features - 20CrMn, process features - composite extrusion, cold extrusion , to retrieve whether there are similar numerical simulation cases.

[0046] 2. Pre-processing parameter input

[0047] After searching, no similar cases were found in the knowledge base, so the introduction of the pre-processing parameters was queried in the knowledge base, some similar cases, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com