Compressed air foam fire-extinguishing apparatus

A technology of compressed air foam and fire extinguishing device, which is applied in the structural field of foam fire extinguishing device and compressed air foam fire extinguishing device, can solve the problems of pressure fluctuation, easy fluctuation, and difficulty in forming compressed air foam, so as to avoid system pressure fluctuation and system The pressure is stable and the effect of meeting the needs of fire extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

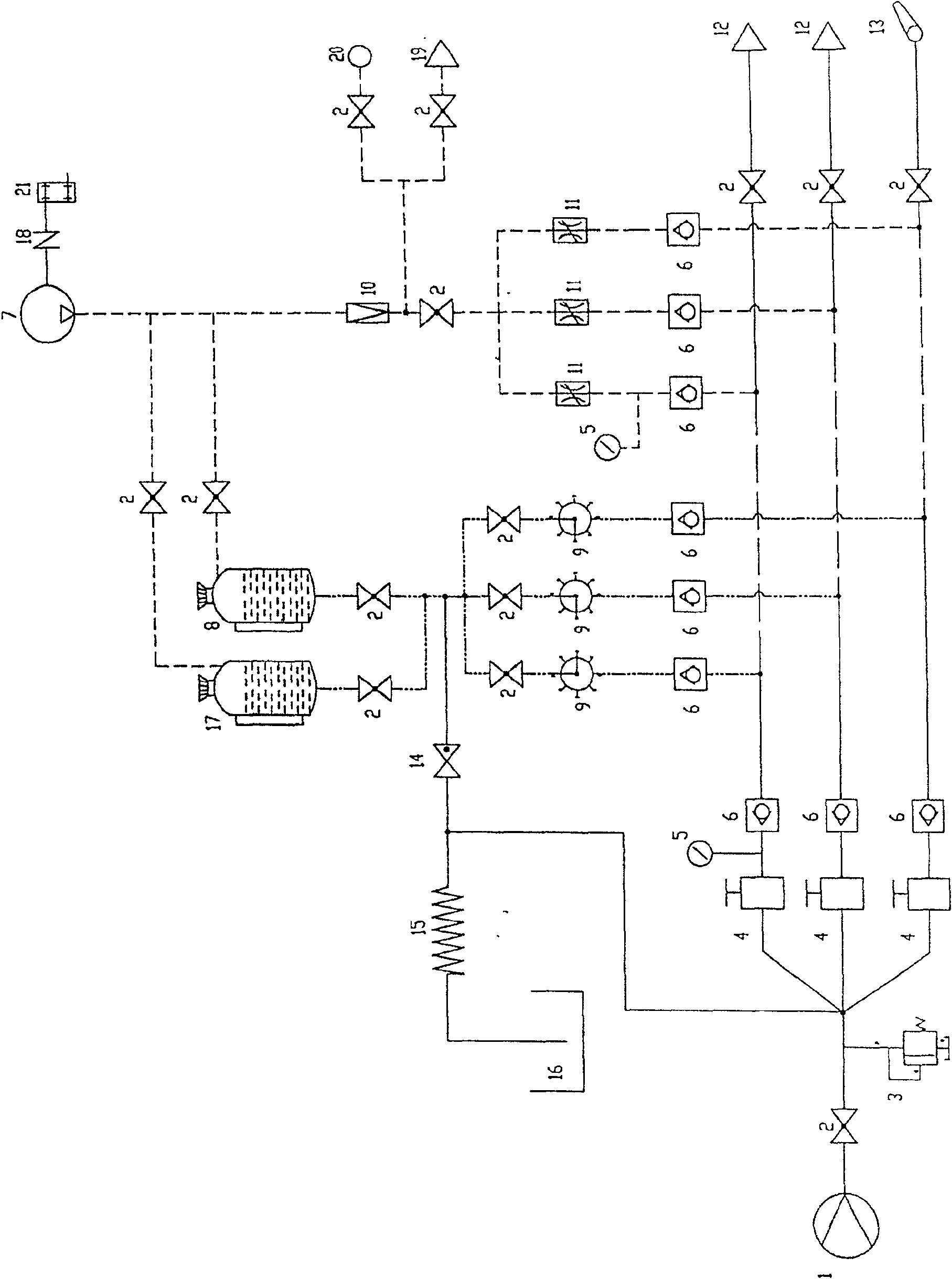

[0017] This embodiment is a kind of compressed air foam fire extinguishing device that can be mounted on a vehicle, such as figure 1 As shown, the power compressed air provided by the air supply end of the screw air compressor 7 leads to the air inlets of the A-type foam liquid storage tank 8 and the B-type foam liquid storage tank 17 respectively through the valve 2, so that the foam liquid therein can flow from the foam liquid storage tank 17 respectively. The outlet is pressed out through another valve 2 and the three-way foam ratio control valve 9, and mixed with the pressure water in the three-way pressure water pipeline according to the required ratio; the pressure water here is provided by the water pump 1, and passes through the three-way pressure water pipeline. Ball valve 2, overflow valve 3, dry and wet foam control valve 4, one-way valve 6, after converging and mixing, enter the water-foam mixed flow pipeline; at the same time, the compressed air provided by screw a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com