Dispensing apparatus for dispensing liquid crystal

A dispenser, liquid crystal technology, applied in liquid distribution, distribution devices, special distribution devices, etc., can solve problems such as uneven distribution of liquid crystals and changes in liquid crystal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

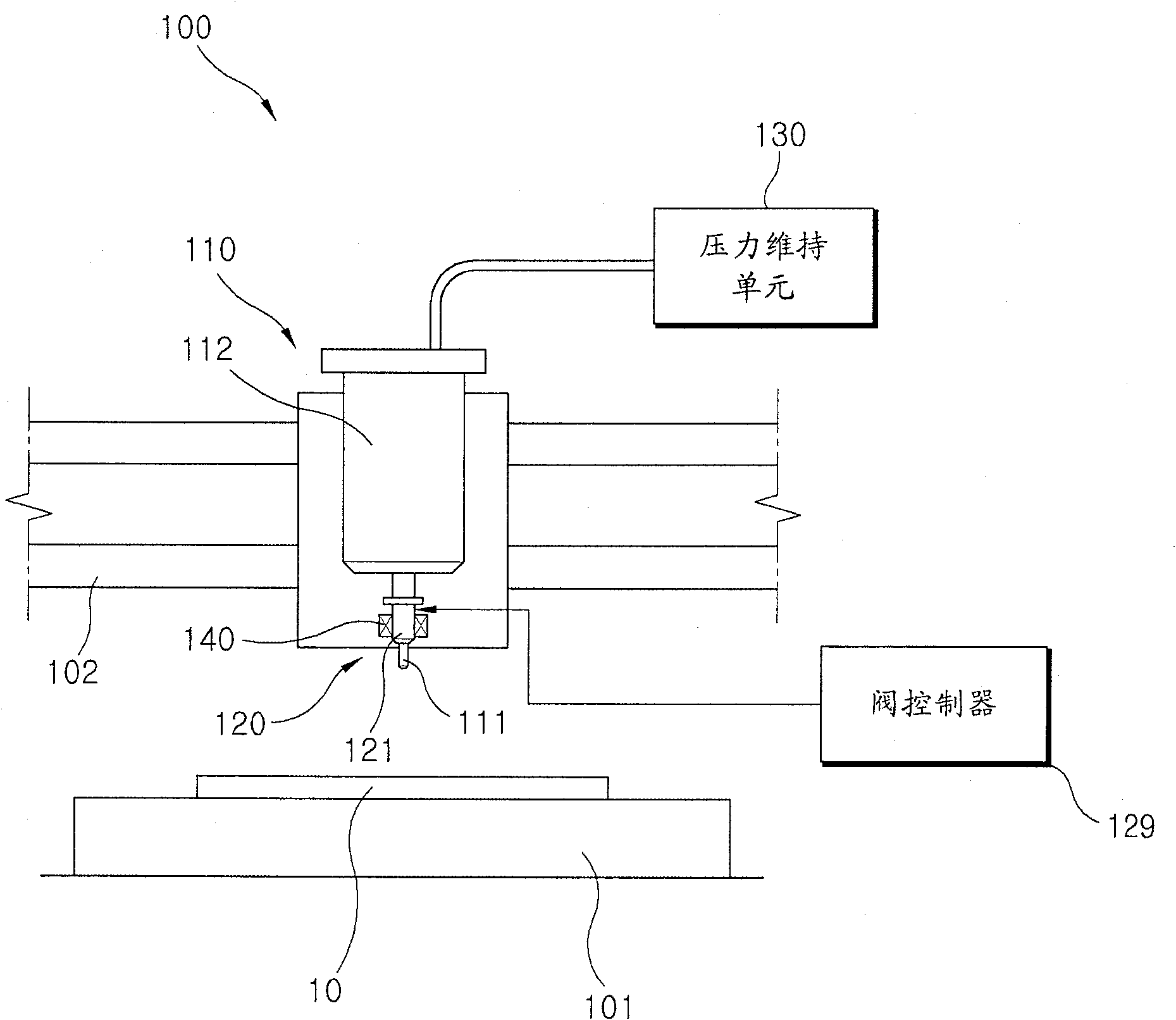

[0023] figure 1 is a view showing the structure of a dispenser for dispensing liquid according to an embodiment of the present invention.

[0024] refer to figure 1 , the dispenser 100 for dispensing liquid according to an embodiment of the present invention includes a nozzle 111 through which liquid such as liquid crystal is dispensed.

[0025] The liquid contained in the syringe 112 is dispensed on the substrate 10 through the nozzle 111 which moves relative to the substrate 10 . The nozzle 111 is provided on the dispensing head unit 110 supported by the head support frame 102 which is movably provided on the main body 101 in one direction. The dispensing head unit 110 is provided to be movable in a direction opposite to the direction in which the head support frame 102 is movable. This makes the nozzle 111 movable r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com