Method for improving antishock performance of double-layer vibration isolating system

A technology of shock resistance and vibration isolation system, applied in the direction of shock absorber, shock absorber-spring combination, propulsion components, etc. It can quickly capture, reduce the source vibration, and improve the vibration isolation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in more detail below in conjunction with accompanying drawing example:

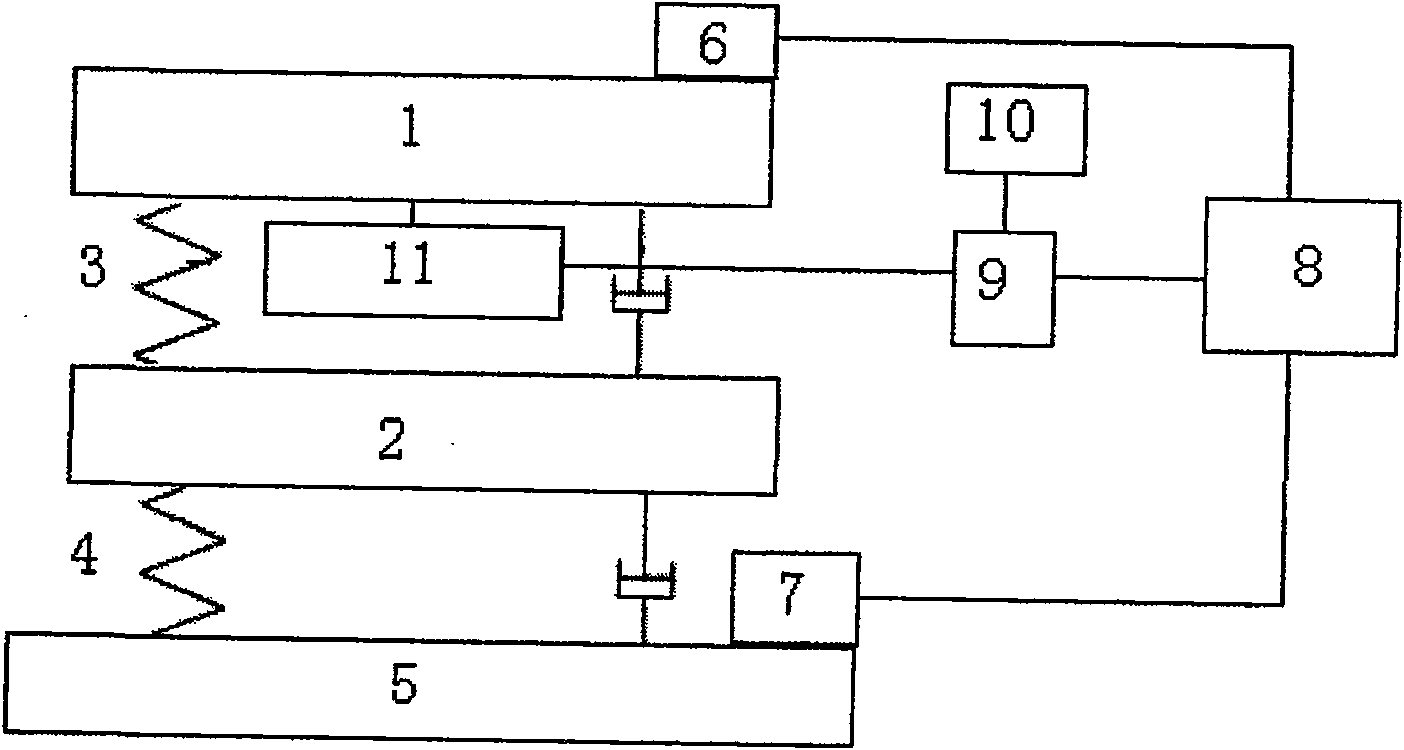

[0032] combine figure 1 , the protected marine power equipment 1, the intermediate mass 2, the elastic shock absorber 3 and the elastic shock absorber 4 as the protected upper mass constitute a double-layer vibration isolation system and are placed on the hull foundation 5; the vibration pickup sensor 6 , pickup sensor 7, DSP controller 8, constant current source circuit 9, DC power supply 10, electromagnetic semi-active shock absorber 11 constitute a semi-active control system. The protected marine power equipment 1 in the double-layer vibration isolation system is equipped with an electromagnetic semi-active vibration absorber 11, and its vibration signal is measured by the vibration pickup sensor 6 as a vibration detection signal, and the shock pickup sensor 7 detects the hull foundation The acceleration signal of 5 is used as the impact judgment signal, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com