Method for setting induction stirring parameter of round blank continuous casting crystallizer

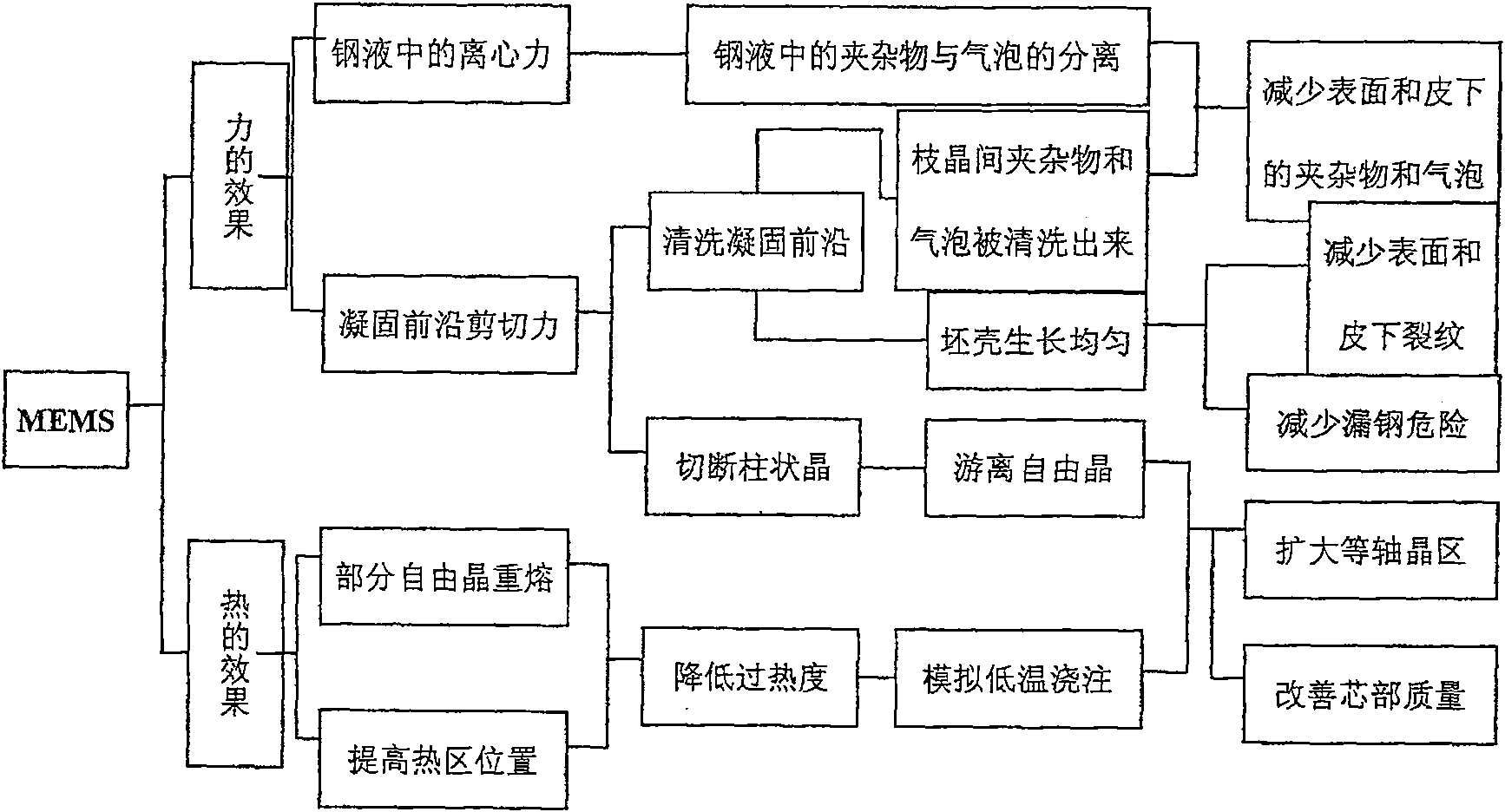

A technology of electromagnetic stirring and continuous casting of round slabs, which is applied in the field of determining the current intensity and frequency of electromagnetic stirring of continuous casting slab molds, and can solve problems such as few research conclusions and large differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

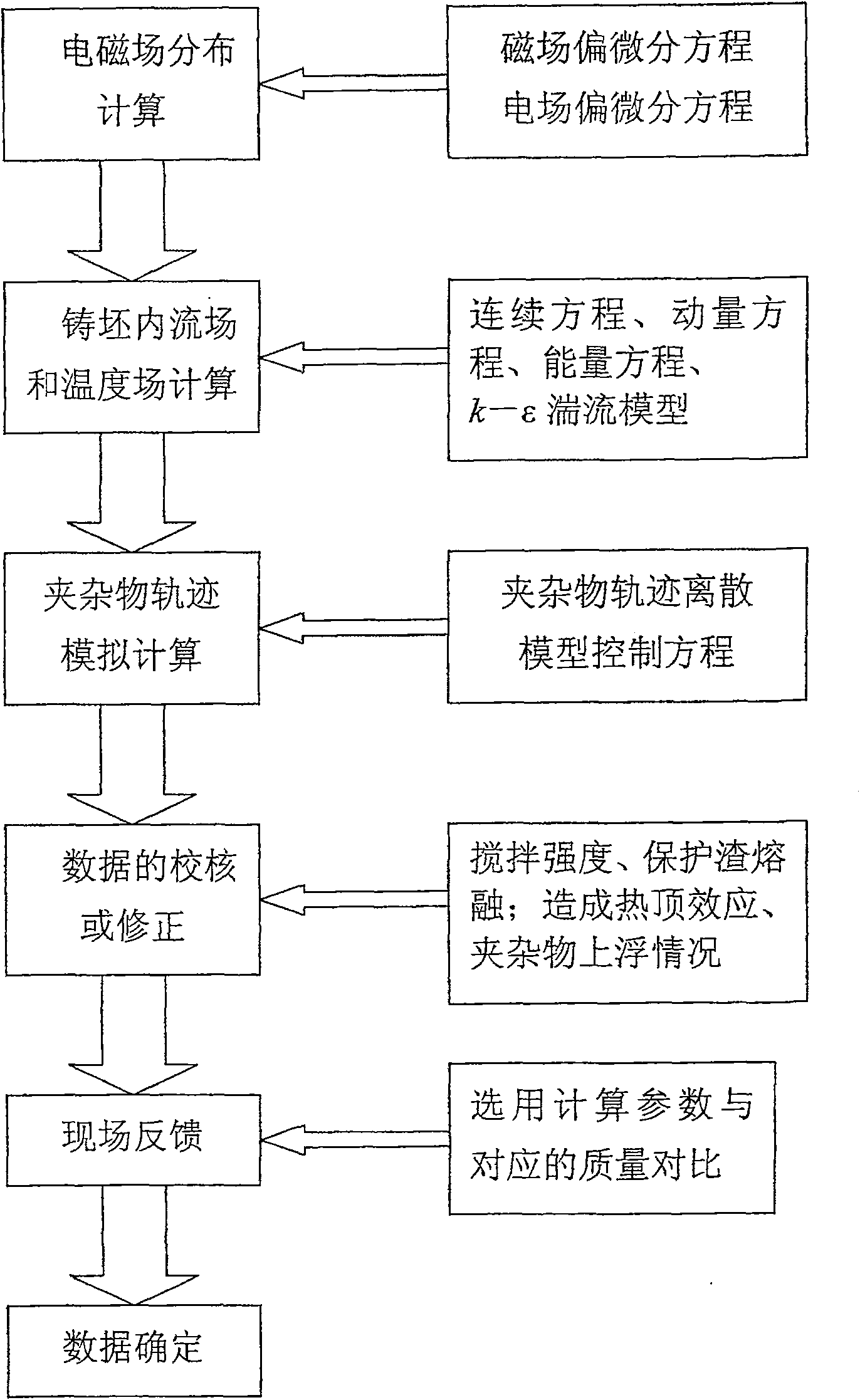

[0022] as attached figure 2 It is an implementation flowchart of the method for formulating electromagnetic stirring parameters of the round billet continuous casting mold of the present invention. The specific steps are as follows.

[0023] 1. The electromagnetic field distribution of the crystallizer electromagnetic stirring.

[0024] To simulate the electromagnetic field phenomenon during the electromagnetic stirring process of the crystallizer, a mathematical model must be established to describe this process. In view of the complexity of the electromagnetic field and flow field coupling problem during the electromagnetic stirring process of the crystallizer, the following assumptions are made in order to make the problem easy to handle without losing its meaning when establishing the mathematical model:

[0025] ① The frequency of the alternating magnetic field used in electromagnetic stirring is generally 1 to 10 Hz, which belongs to the magnetic quasi-static field, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com