Platform mold inspection device

An inspection device and a platform-type technology, applied in the field of platform-type mold inspection devices, can solve the problems of occupying a die-casting machine, affecting the normal progress of die-casting production, and failing to make a successful mold at one time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

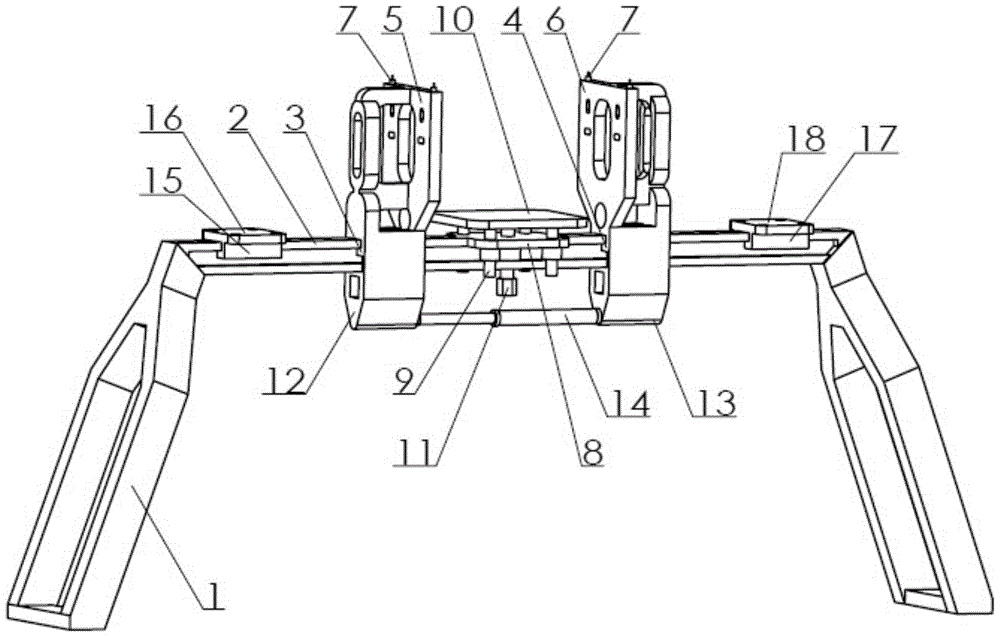

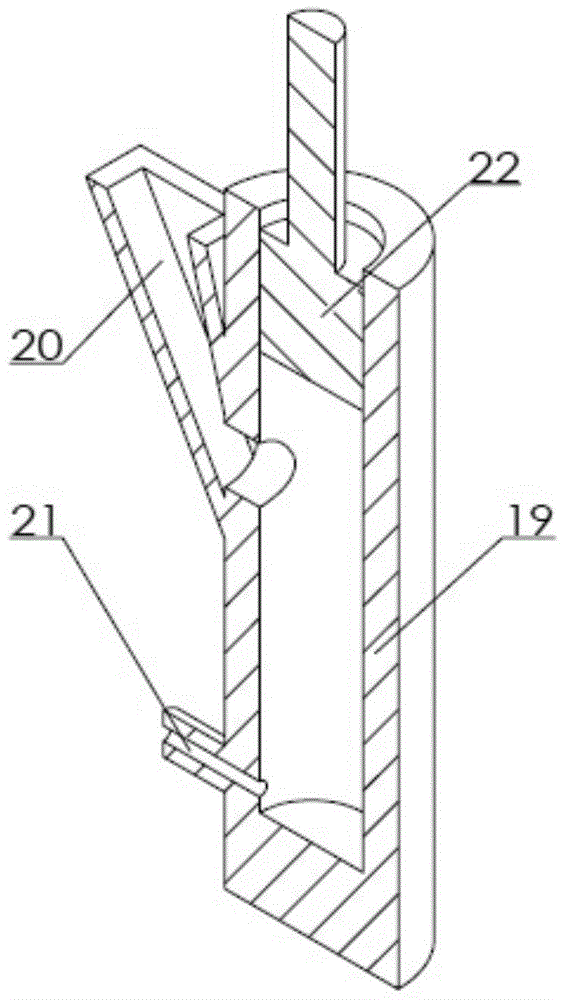

[0013] Embodiments of the present invention are as figure 1 , 2 As shown, the platform type mold inspection device includes a horizontal guide rail 2 supported by a bracket 1, the bracket is located at both ends of the horizontal guide rail, and the left mold frame slider 3 and the right mold frame slider 4 are matched on the horizontal guide rail. A static mold connecting plate 5 whose connecting surface is perpendicular to the direction of the horizontal guide rail is arranged above the slider, and a moving mold connecting plate 6 whose connecting surface is perpendicular to the direction of the horizontal guide rail is arranged above the right mold frame slider. The static mold connecting plate and the moving mold connecting plate The inside is provided with heating devices respectively. This embodiment is a built-in electric heating tube 7, and electromagnetic heating can also be used to preheat the connected moulds; Rectangular platform 8, the four corners of rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com