Low NOx DC micro-oil coal powder burner

A pulverized coal burner and burner technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve the problems of low NOx combustion characteristics, human health hazards, environmental pollution, etc., to reduce emissions, turbulence The effect of enhancing the effect and saving ignition oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

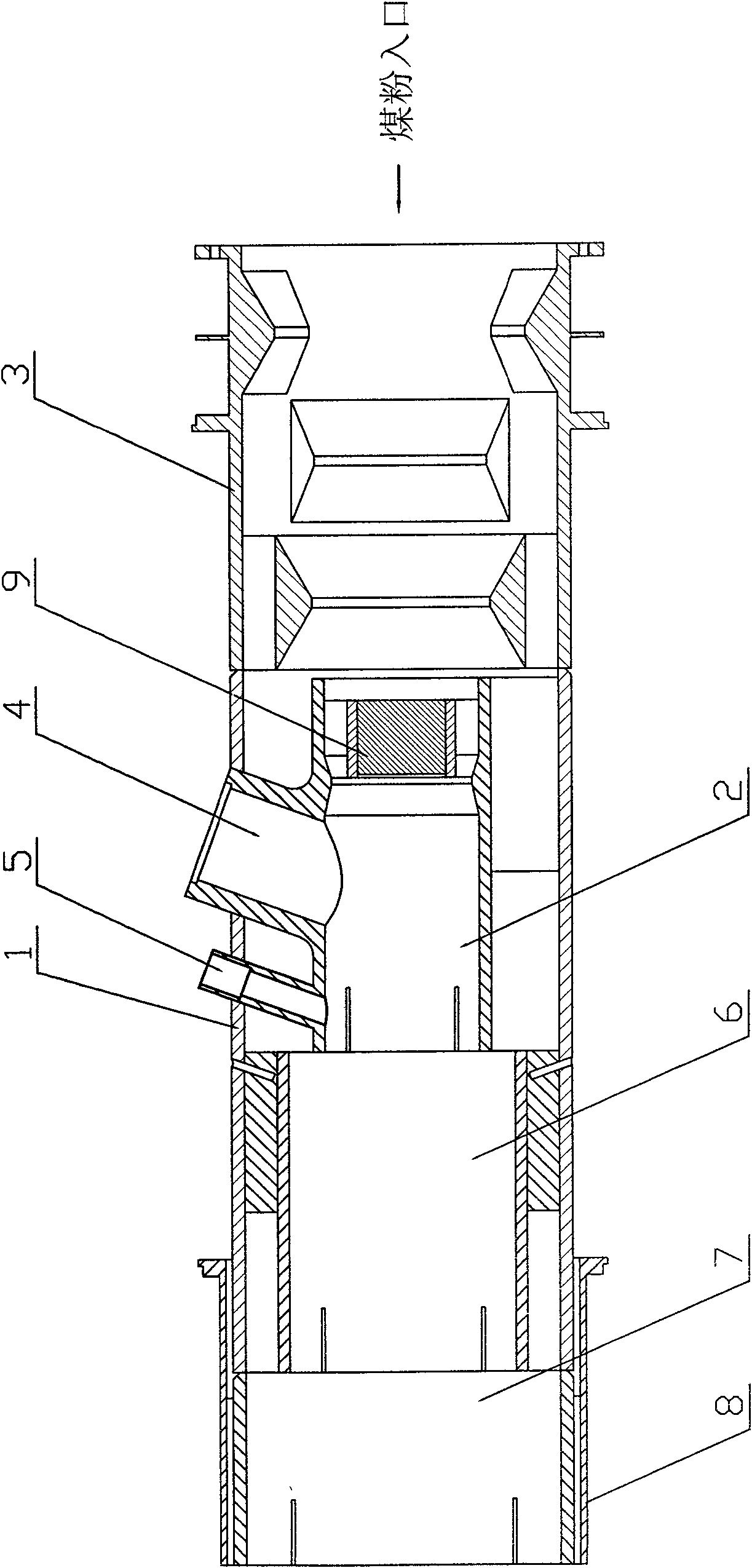

[0015] see figure 1 , the present invention includes a burner body 1 and a primary combustion chamber 2 placed in the burner body 1, an annular pulverized coal concentrator 3 is provided at the entrance of the burner body 1, and an oil combustion chamber 4 is obliquely inserted from the burner body 1 In the primary combustion chamber 2, in order to observe the situation in the combustion chamber, an observation port 5 is obliquely inserted into the primary combustion chamber 2 from the burner body 1. According to actual needs, a secondary combustion chamber 6 and a tertiary combustion chamber 7 can also be set. , The outlet of the burner body 1 is provided with a film air inlet 8, and a cooling air with a relatively low temperature enters from the air film air inlet 8 to cool the wall of the burner, thereby prolonging the service life of the burner.

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com