Cavity filter test system and method

A cavity filter and test system technology, applied in the electronic field, can solve problems such as difficult time determination, difficult control error, and increased test difficulty, and achieve the effects of increased convenience of use, fast air pressure balance, and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

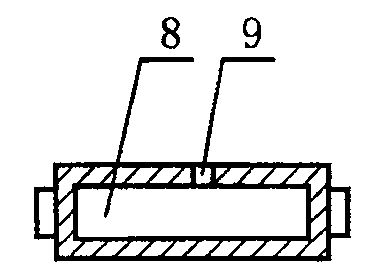

[0035] Such as figure 2 As shown, the cavity of the cavity filter is provided with vent holes 9 for communicating the inner cavity 8 with the outside world. The vent hole 9 is set on the device cavity of the cavity filter, and can be set on each surface, and can even be set at the device pin of the cavity filter, as long as the air can be extracted in the follow-up work Just belong to the scope of the present invention.

Embodiment 2

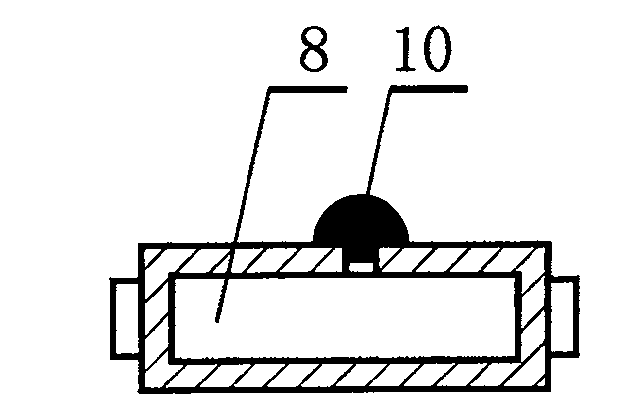

[0037] Such as image 3 As shown, on the basis of the first embodiment, the air hole 9 is also provided with a sealing plug 10 for the purpose of realizing the airtightness of the cavity filter itself after the test is completed. Normally, the sealing plug 10 can be realized with paraffin wax, sealant such as silica gel, wax, etc. Of course, for the standardization of production, the sealing plug 10 can also be an independent component made of sealing materials such as rubber.

[0038] At the same time, there is at least one vent hole 9, that is to say, in order to reach the required target value more quickly, a plurality of vent holes 9 can be provided at the same time.

Embodiment 3

[0040] Such as Figure 4 As shown, on the basis of Embodiment 1 or Embodiment 2, an interface 11 may also be provided at the ventilation hole 9, and the interface 11 is used to connect a ventilation pipeline 12.

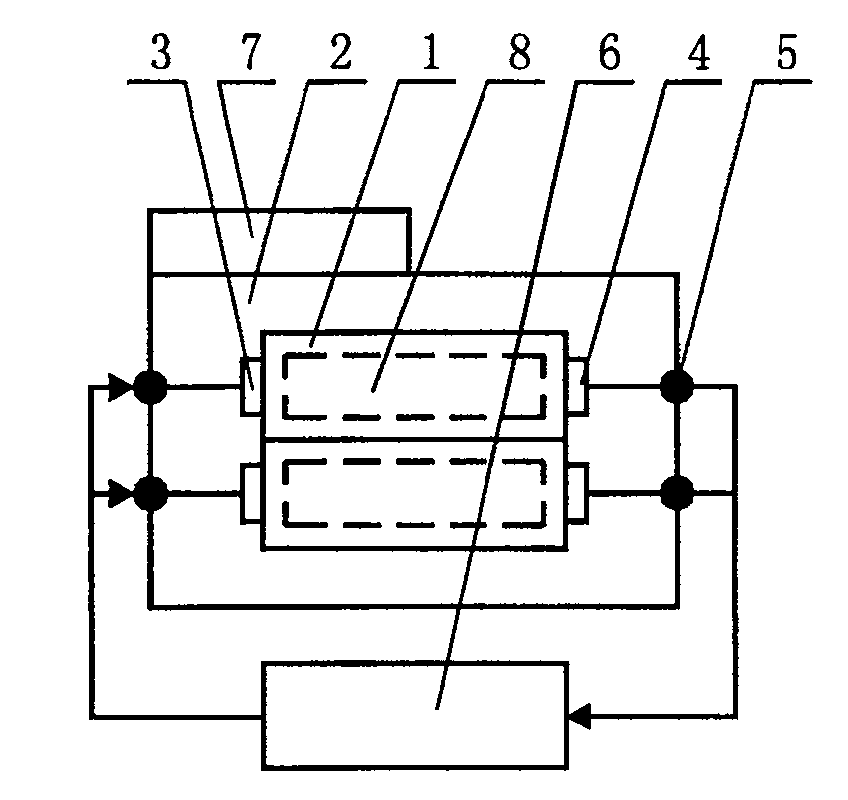

[0041] A cavity filter testing system according to the present invention is used for testing the above-mentioned cavity filter, and its specific implementation is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com