Protein additive for ruminant foodstuff and its preparation

A technology for ruminants and additives, applied in animal feed, animal feed, applications, etc., can solve the problems of excessive ammoniacal nitrogen, animal poisoning, etc., and achieve the effect of reducing the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

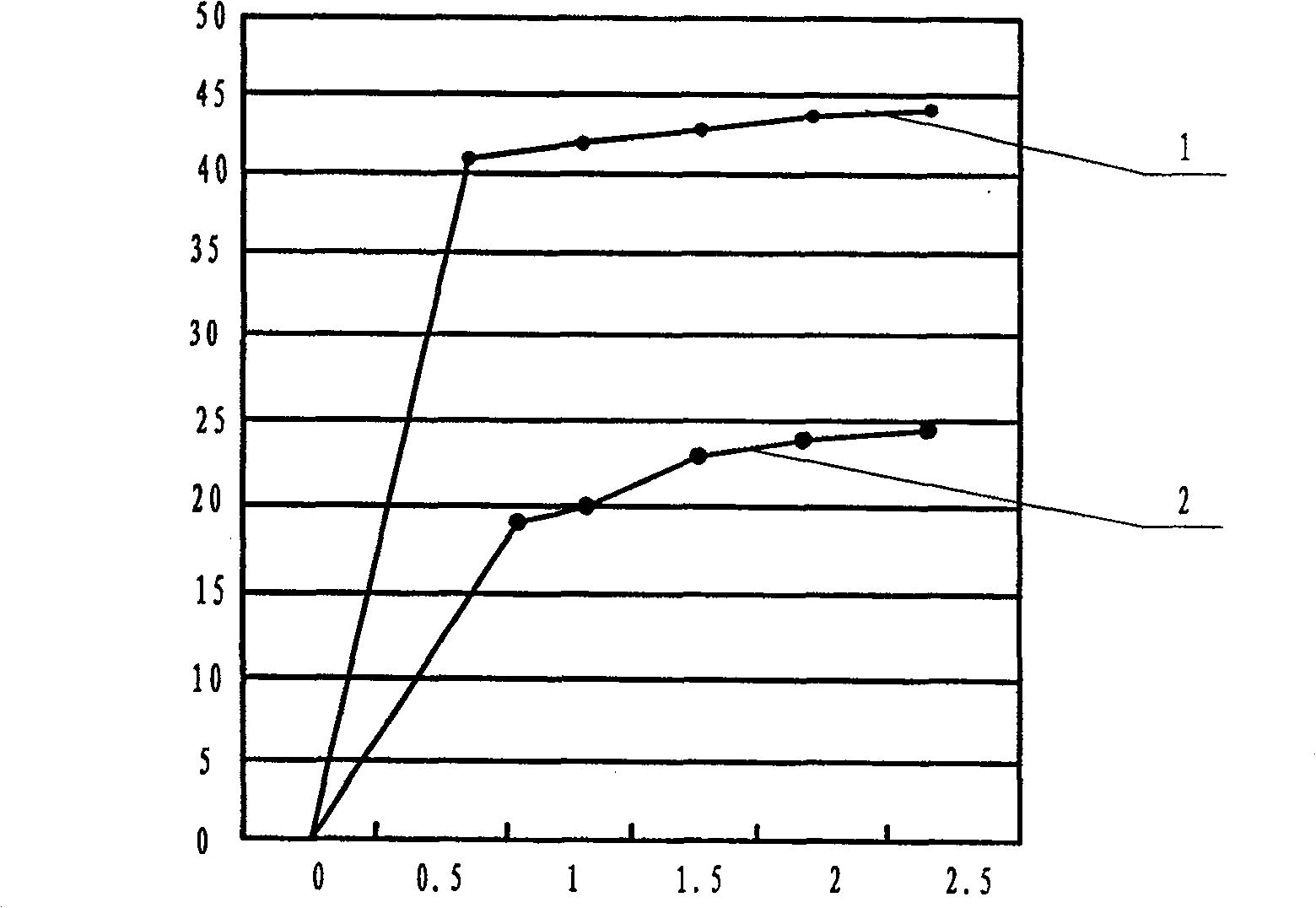

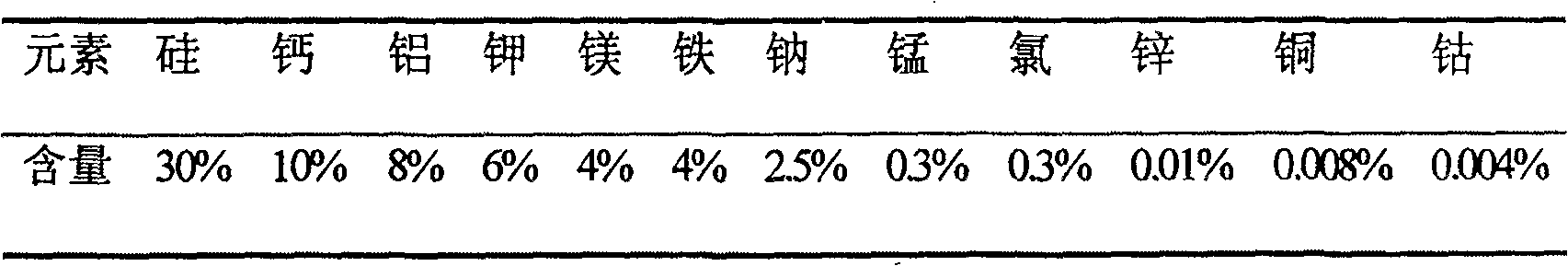

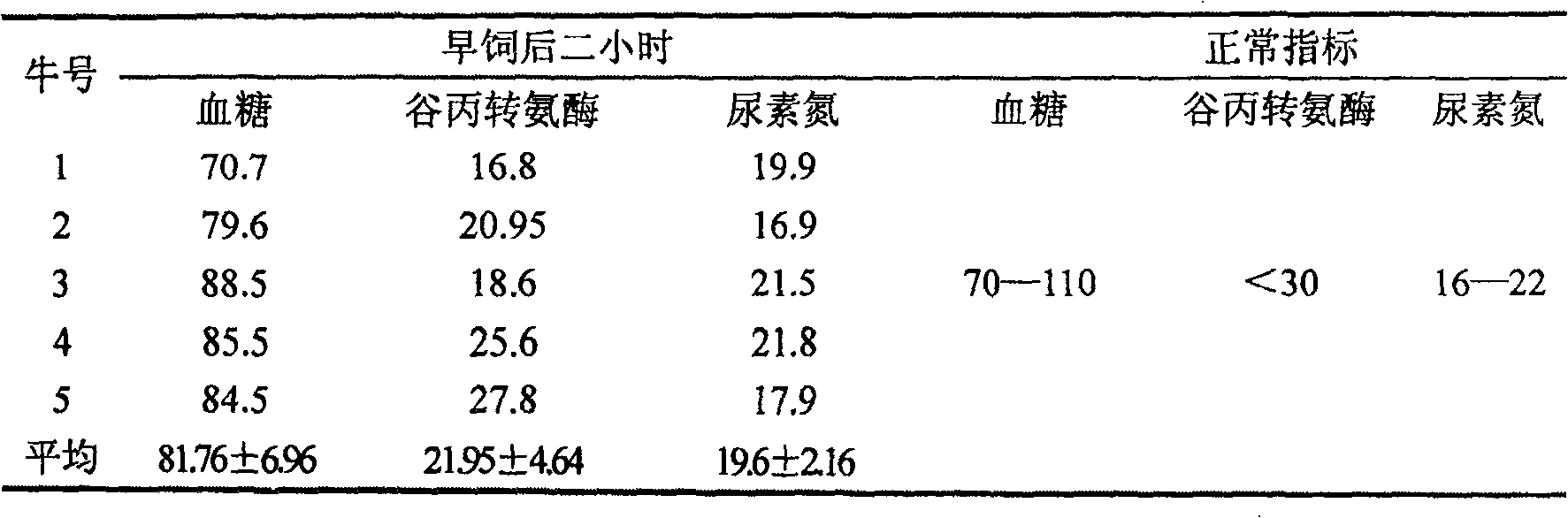

Method used

Image

Examples

Embodiment 1

[0055] The formula of protein additive is 60% corn flour, 30% urea, 9% bentonite, 1% sodium diacetate and Bacillus subtilis preparation 0.5% (external ratio), and its preparation method is as follows: corn flour, urea, bentonite, diacetic acid Sodium is subjected to quality inspection, purification, crushing and other preprocessing procedures of inspection, purification, and crushing; then strictly according to the formula ratio, various raw materials are accurately weighed, and fully mechanically stirred after mixing; the fully stirred mixed material is then passed through the mill The chip pulverizer is mixed, kneaded and crushed to make the material fineness reach 10 mesh; calculate the moisture content of the mixed material according to the moisture content of different raw materials, and adjust its moisture content to 15%; then mix the material at a temperature of 110°C Gelatinization and extruding into strips under the condition of 10s time; finally, after the material is...

Embodiment 2

[0057] The formula of protein additive is 70% corn flour, 20% urea, 9.5% bentonite, 0.5% sodium diacetate and Bacillus subtilis preparation 1.5% (external ratio), and its preparation method is as follows: corn flour, urea, bentonite, diacetic acid Sodium is subjected to quality inspection, purification, crushing and other preprocessing procedures of inspection, purification, and crushing; then strictly according to the formula ratio, various raw materials are accurately weighed, and fully mechanically stirred after mixing; the fully stirred mixed material is then passed through the mill The chip pulverizer is mixed, kneaded and pulverized so that the fineness of the material reaches 50 mesh; according to the moisture content of different raw materials, the moisture content of the mixed material is calculated, and the optimum water content is adjusted to 25%; then the mixed material is heated at a temperature of Under the conditions of 150°C and 60s, gelatinize and extrude into ...

Embodiment 3

[0059] The formula of protein additive is 65% corn flour, 25% urea, 8.5% bentonite, 1.5% sodium diacetate and Bacillus subtilis preparation 1% (external ratio), and its preparation method is as follows: corn flour, urea, bentonite, diacetic acid Sodium is subjected to quality inspection, purification, crushing and other preprocessing procedures of inspection, purification, and crushing; then strictly according to the formula ratio, various raw materials are accurately weighed, and fully mechanically stirred after mixing; the fully stirred mixed material is then passed through the mill The chip pulverizer performs secondary crushing to make the material fineness reach 100 mesh; calculate the moisture content of the mixed material according to the moisture content of different raw materials, and adjust the optimal moisture content to 20%; then mix the material at a temperature of Gelatinize at 140°C for 20s and extrude into strips; finally, spray 1% Bacillus subtilis preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com