Symmetrical straight beam structure condenser type micro-acceleration sensor and manufacturing method thereof

A technology of acceleration sensor and structural capacitance, which is applied in the direction of measuring acceleration, velocity/acceleration/shock measurement, instruments, etc., can solve the problems of not being able to significantly reduce the cross-axis sensitivity and large lateral sensitivity of the device, and achieve the reduction of cross-sensitivity and simplify the process , Improve the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

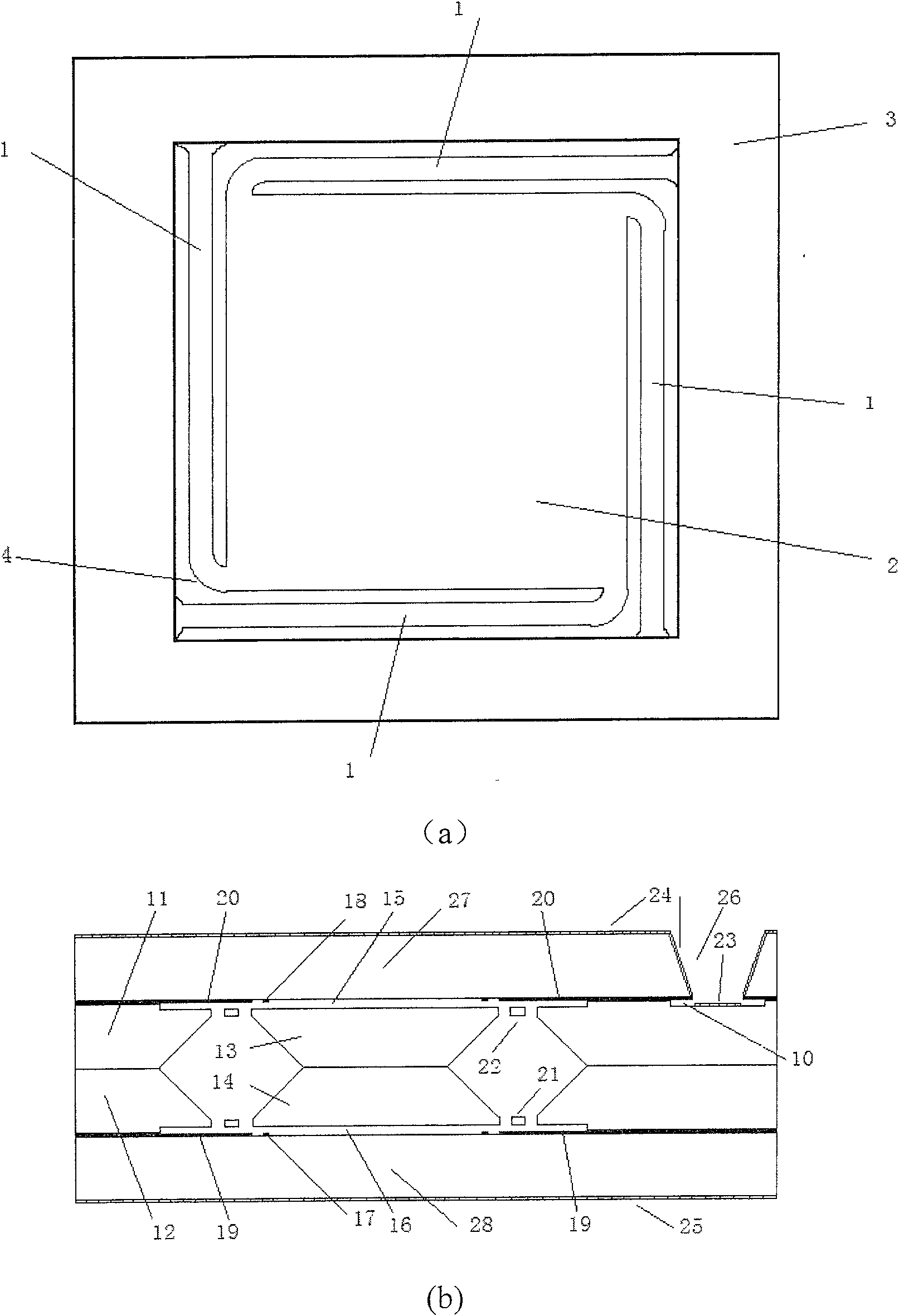

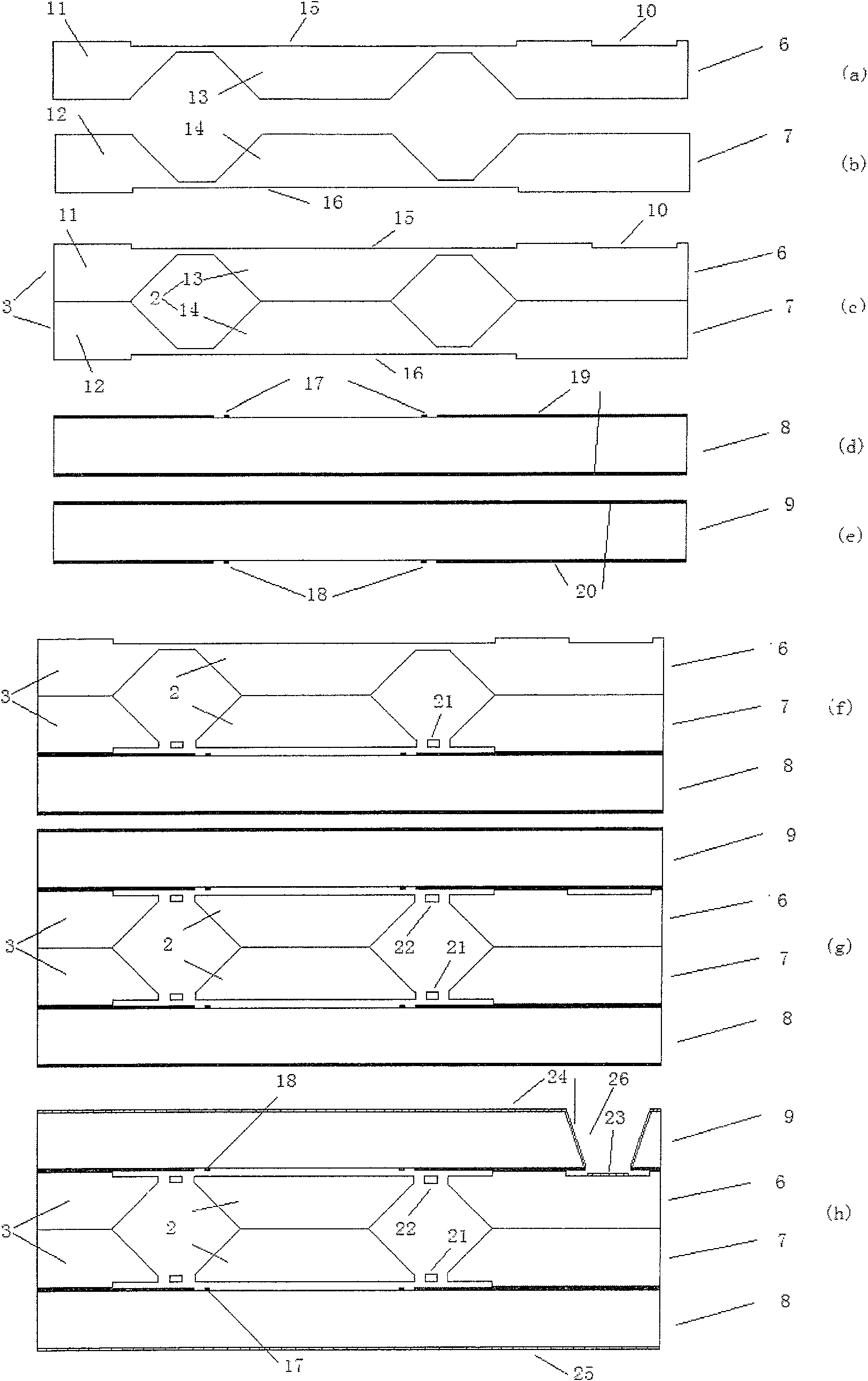

[0044] Embodiment 1 of the present invention relates to a micro-acceleration sensor structure, combined with the attached figure 1 illustrate.

[0045] Such as figure 1 As shown in (a), one end of the straight elastic beam 1 is connected to the top corner of the central mass 2 through the short beam 4, and the other end is connected to the external support frame 3 perpendicular to it. Such as figure 1 As shown in (b), the micro-acceleration sensor structure includes a centrally symmetrical mass block 2, an external support frame 3, eight up and down symmetrical straight elastic beam structures 1 connected to the centrally symmetrical mass block 2 and the external support frame 3, and an upper Cover plate 27, lower cover plate 28. The mass block 2 is composed of the top mass block silicon chip 6 and the bottom mass block silicon chip 7, the straight elastic beam structure 1 is composed of the top elastic beam 22 and the bottom elastic beam 21, and the external support frame ...

Embodiment 2

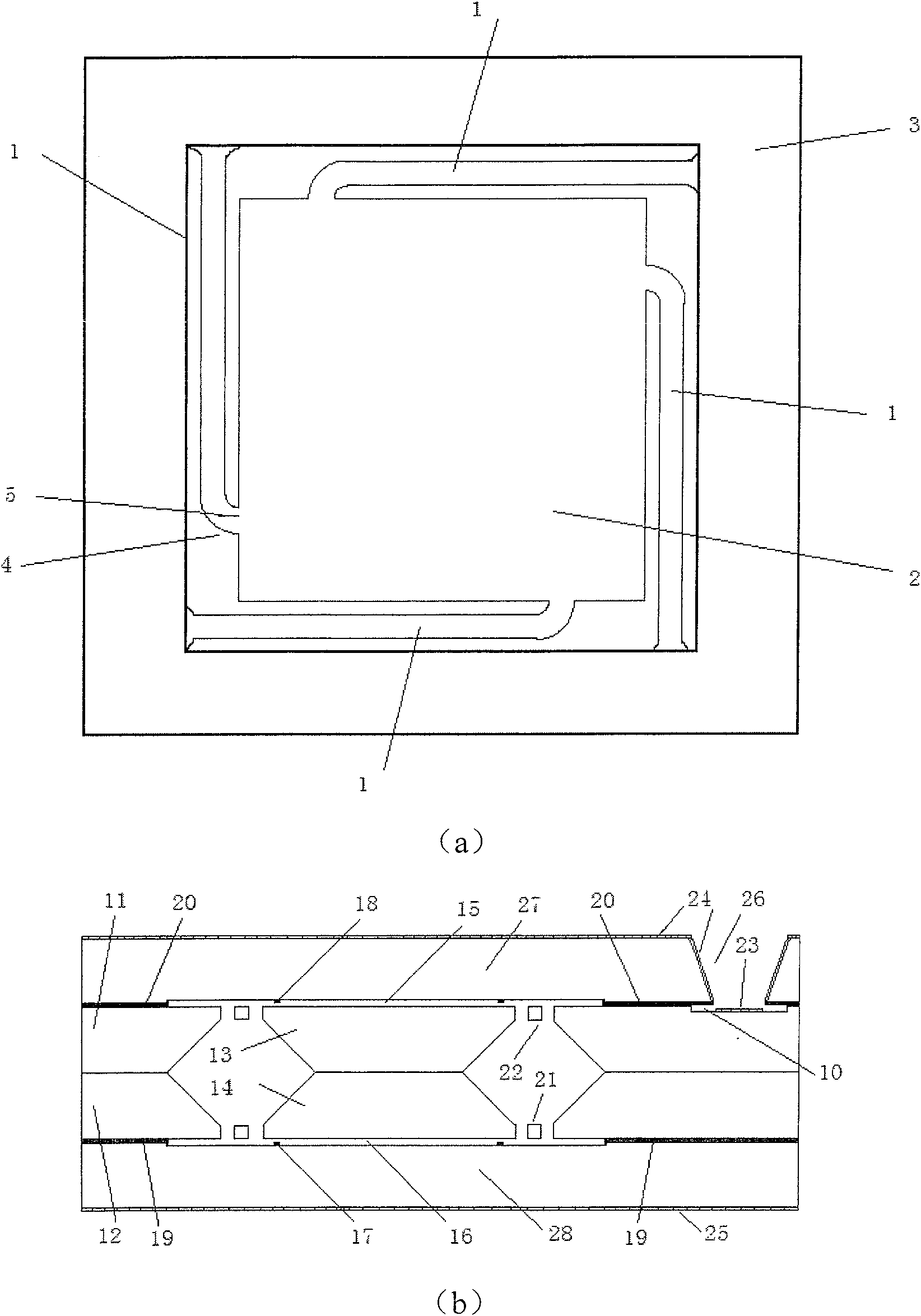

[0057] Embodiment 2 of the present invention relates to another micro-acceleration sensor structure. The difference from Embodiment 1 is that the distribution of straight elastic beams and the positions of capacitance gaps are different. image 3 illustrate.

[0058] Such as image 3 As shown in (a), one end of the straight elastic beam 1 is connected to any position 5 of the central mass 2 along its side length except the top corner through the short beam 4, and the other end is connected to the external support frame 3 perpendicular to it. Such as image 3 As shown in (b), the micro-acceleration sensor structure includes a centrally symmetrical mass block 2, an external support frame 3, eight vertically symmetrical straight elastic beam structures 1 connected between the mass block 2 and the external support frame 3, and an upper cover plate 27 , Lower cover plate 28. The centrosymmetric mass block 2 is composed of the top mass block silicon chip 6 and the bottom mass blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com