High performance homogeneous viscose filament and manufacturing method thereof

A viscose filament, high-performance technology, applied in the textile field, can solve the problems affecting viscose filament, etc., and achieve the effect of easy implementation, simple process and great promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 The manufacture method of high-performance homogeneous wood pulp viscose filament

[0017] Taking 75D81m / min and setting the total spinning time as 66300 s as an example, the spinning dope produced by conventional technology is transported to the pre-spinning process. The pre-spinning glue index: viscosity 30-34 s, maturity 10ml.

[0018] The glue is supplied by the metering pump, and the glue supply is 6.22ml / min. On this basis, the glue supply of the metering pump is compensated by -0.5-5.6% in 8 time periods; The concentration of the acid bath is 128-131g / l, using a single ingot to feed and return acid, to control the amount of acid entering and returning, to reduce the acid bath drop and acid bath temperature difference between ingots, ingots, distinctions and distinctions, and between machines. Make the drop of acid bath ≤2g / l, and control the temperature difference of acid bath at 50±0.5°C; It is also divided into the same 8 time periods, and the spe...

Embodiment 2

[0020] The manufacture method of embodiment 2 high-performance homogeneous cotton paddle viscose filament

[0021] Taking 120D89.9m / min and setting the total spinning time as 36900S as an example, the spinning dope produced by conventional technology is transported to the pre-spinning process. The pre-spinning glue index: viscosity 30-34S, maturity 10ml.

[0022] The glue is supplied by the metering pump, and the glue supply is 10.78ml / min. On this basis, the glue supply of the metering pump is compensated by -1-8% in 6 time periods; bath, the acid bath concentration is

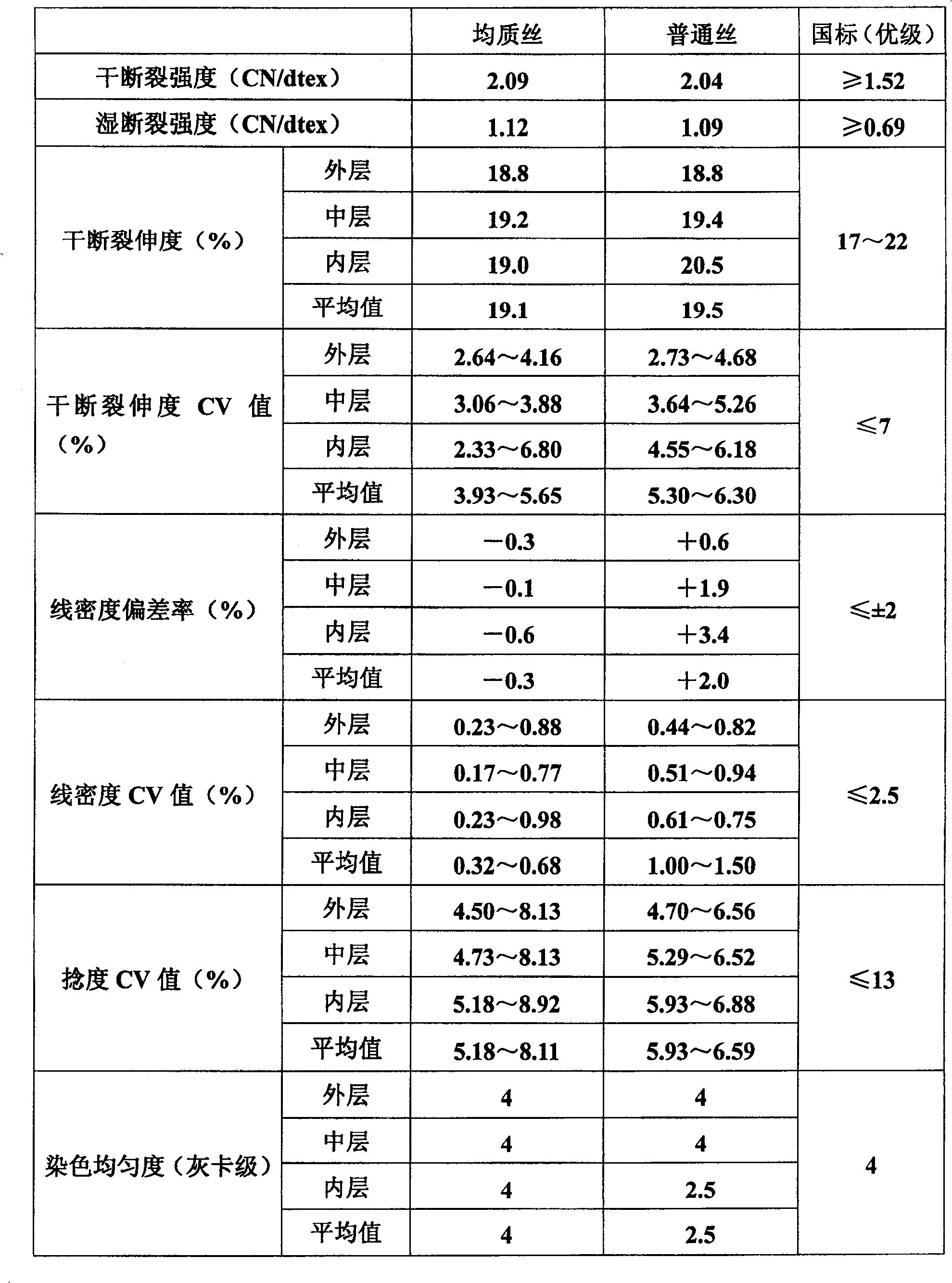

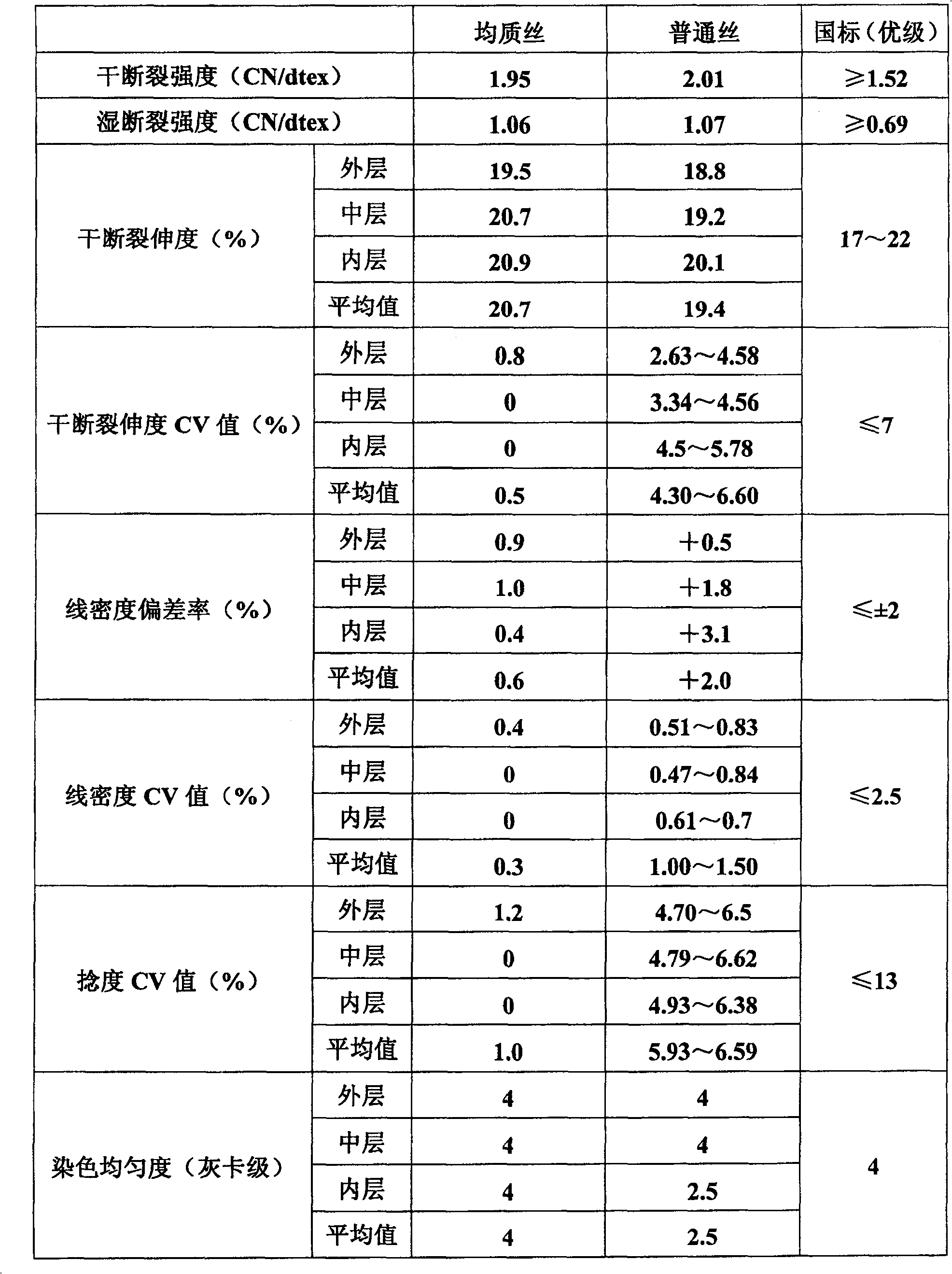

[0023] Table 1

[0024] 0-

12540s

12540-

20900s

20900-

29260s

29260-

37620s

37620-

45980s

45980-

54340s

54340-

62700

62700-

66300

Metering pumps(%)

0

-0.5

2.5

3.7

5.6

4.1

3.2

2.5

Coagulation roll (%)

0

1

2.2

3.5

4.8

6...

Embodiment 3

[0029] The manufacture method of embodiment 3 high-performance homogeneous bamboo pulp viscose filament

[0030] Taking 250D80m / min and setting the total spinning time as 28800S as an example, the spinning dope produced by conventional technology is transported to the pre-spinning process. The pre-spinning glue index: viscosity 30-34S, maturity 10ml.

[0031] The glue is supplied by the metering pump, and the glue supply is 20.35ml / min. On this basis, the glue supply of the metering pump is compensated by 0-8% in 4 time periods; through the filter, curved pipe, spinneret to the acid bath , the acid bath concentration is 128-131g / l, using a single ingot to feed and return acid, control the amount of acid entering and returning, reduce the difference between ingots, ingots, distinctions and distinctions, and the acid bath drop and acid bath temperature difference between machines, so that the acid The bath drop is ≤2g / l, and the temperature difference of the acid bath is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com