Vapor seal liquid-suction non-contact type hydrojet grinding wheel for numerical control polishing

A non-contact, polishing liquid technology, applied in the direction of optical surface grinder, grinding/polishing equipment, grinding machine, etc., can solve the problems that the polishing liquid cannot be collected in time, affect the polishing accuracy, and erode the non-polishing area, so as to achieve uniformity Guarantee, avoid local stress, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

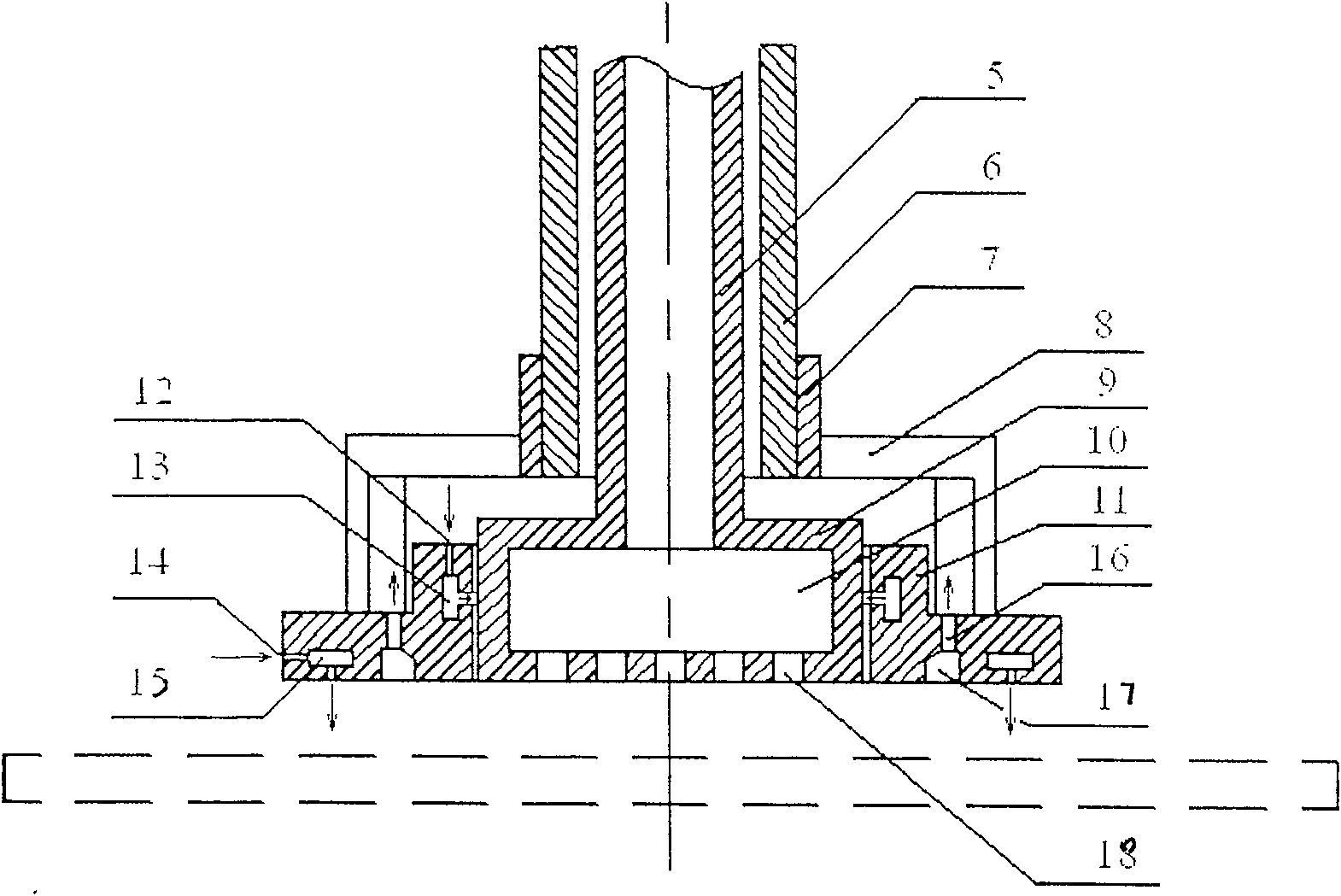

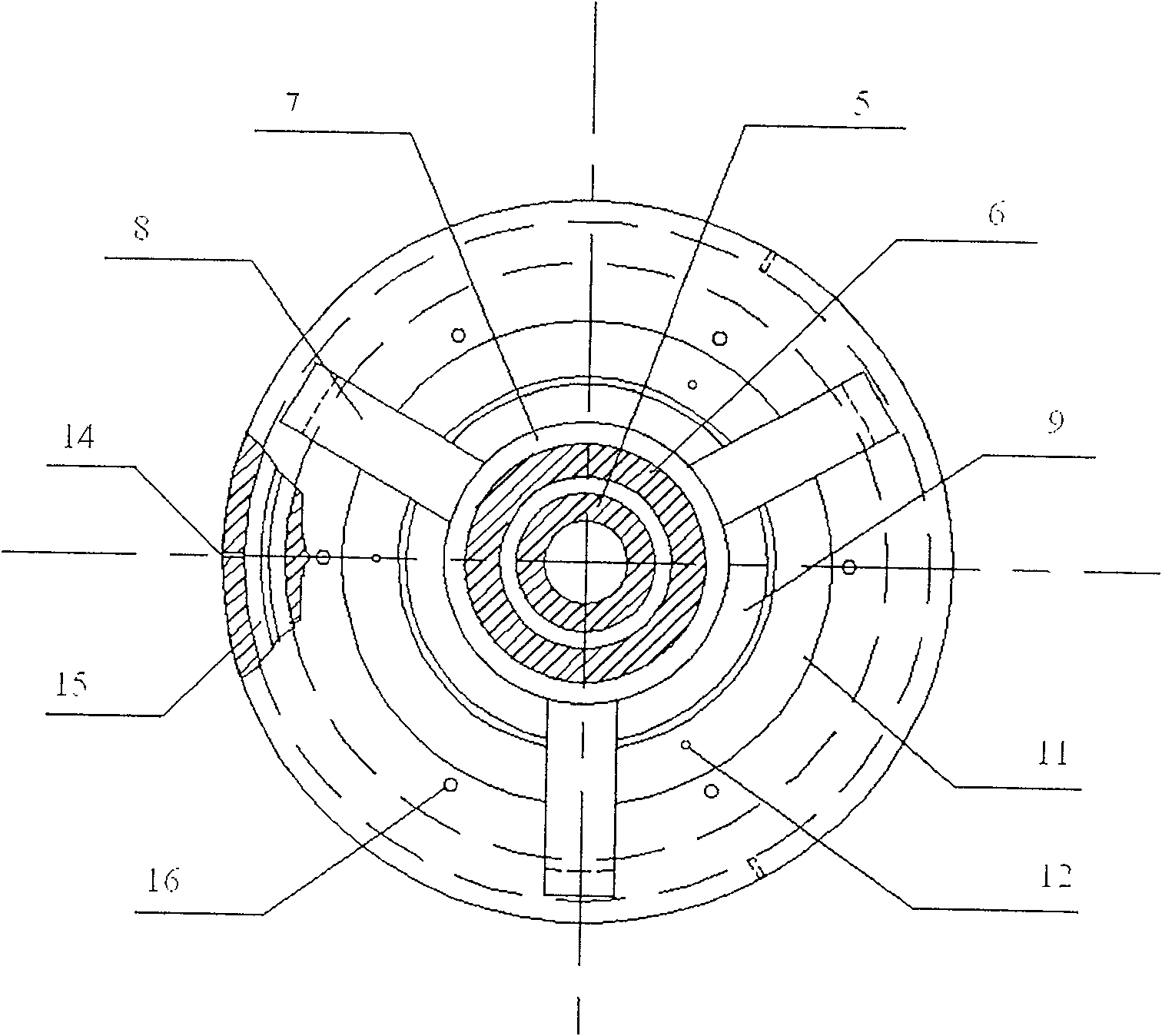

[0014] The invention according to figure 2 with image 3 The structure shown is implemented. Wherein the hollow drive shaft 5, the grinding head shaft sleeve 6, the grinding head connecting sleeve 7, the collecting tray connecting frame 8, the hollow grinding head 9, and the polishing fluid collecting tray 11 are made of stainless steel. Hollow driving shaft 5 and hollow grinding head 9 are integral hollow parts or two parts are for coordinating hollow parts, and so-called cooperation is that two parts are glued or threaded. The grinding head axle sleeve 6 is connected with the grinding head connecting sleeve 7 by bolts or threads. The connection between the collecting plate connecting frame 8 and the grinding head connecting sleeve 7 and the polishing liquid collecting plate 11 is welded. The size of the polishing liquid collecting disc 11 is related to the size of the hollow grinding head 9, generally twice the size of the hollow grinding head, and the gap between the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com