Preparation method of biological microelectrode array based on flexible substrate

A micro-electrode array and flexible substrate technology, applied in the field of biomedical engineering, can solve the problems of unfavorable device biocompatibility, toxicity of corrosive liquid, etc., and achieve the effects of high yield, low impedance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

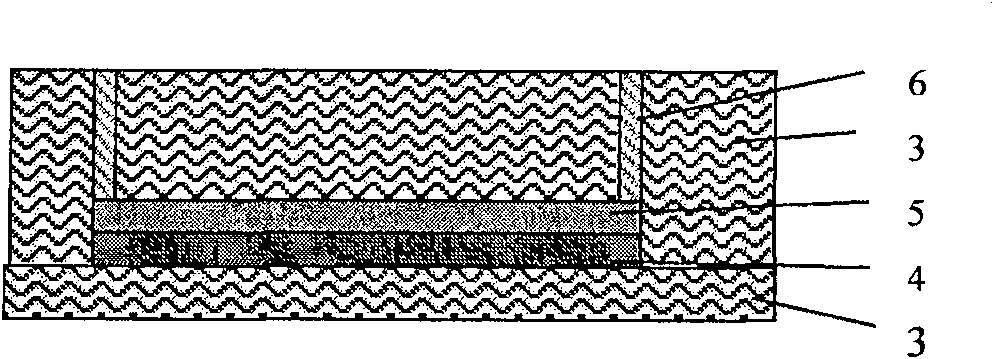

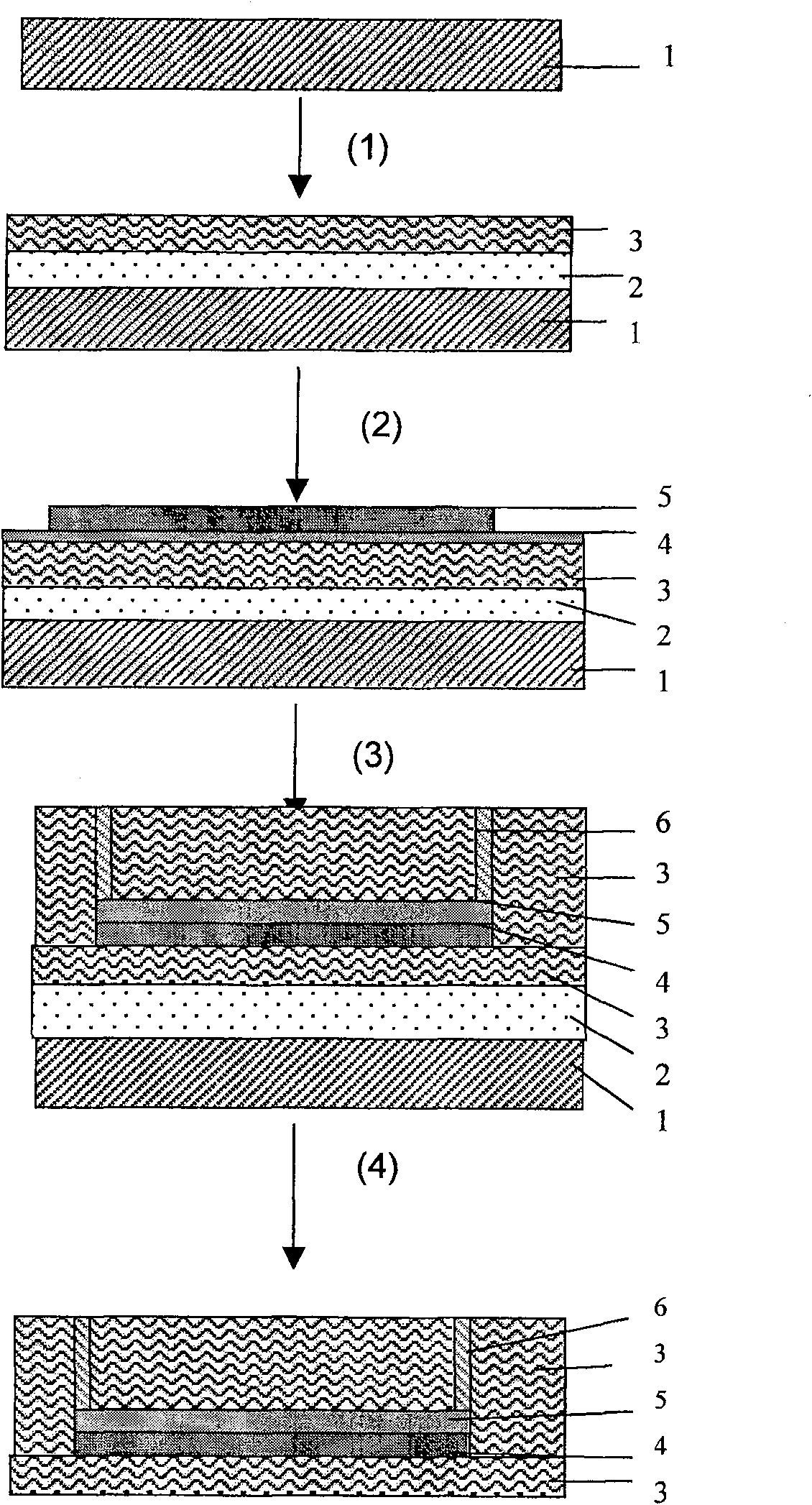

[0020] Structural parameters of biological microelectrode array: glass substrate, polydimethylsiloxane thickness 100 μm, polyimide thickness 50 μm, gold circuit height 2 μm, gold electrode height 5 μm.

[0021] (1) Preparation of flexible substrate

[0022] A glass sheet with a thickness of 2 mm was used as the substrate 1, and the substrate was firstly treated by ultrasonic cleaning with acetone, alcohol and deionized water, and dried in a vacuum oven at 180° C. for 3 hours. Then spin-coat polydimethylsiloxane 2 with a thickness of 100 μm on the substrate at a speed of 1000 rpm, and cure at 80° C. for 2 hours, then spin-coat polyimide acid with a thickness of 50 μm at a speed of 1000 rpm. The flexible base polyimide 3 is formed by thermal curing using a stepwise heating method (from 80° C. to 120° C. to 180° C. to 280° C.).

[0023] (2) Fabrication of metal metal circuits

[0024] First, sputter 50nm Cr / Cu metal base film 4 on the surface of flexible substrate polyimide 3, ...

Embodiment 2

[0030] Structural parameters of biological microelectrode array: glass substrate, polydimethylsiloxane thickness 300 μm, polyimide thickness 20 μm, gold circuit height 1 μm, gold electrode height 3 μm.

[0031] (1) Preparation of flexible substrate

[0032] A glass sheet with a thickness of 2 mm was used as the substrate 1, and the substrate was firstly treated by ultrasonic cleaning with acetone, alcohol and deionized water, and dried in a vacuum oven at 180° C. for 3 hours. Then spin-coat polydimethylsiloxane 2 with a thickness of 300 μm on the substrate at a speed of 700 rpm, and cure at 90° C. for 2 hours, then spin-coat polyimide acid with a thickness of 20 μm at a speed of 2000 rpm. The flexible base polyimide 3 is formed by thermal curing by a stepwise heating method (from 80° C. to 120° C. to 180° C. to 280° C.).

[0033] (2) Fabrication of metal circuits

[0034]First, sputter 100nm Cr / Cu metal base film 4 on the surface of flexible substrate polyimide 3, spin-coat ...

Embodiment 3

[0040] Structural parameters of biological microelectrode array: glass substrate, polydimethylsiloxane thickness 500 μm, polyimide thickness 100 μm, copper circuit height 10 μm, gold electrode height 1 μm.

[0041] (1) Preparation of flexible substrate

[0042] A glass sheet with a thickness of 2 mm was used as the substrate 1, and the substrate was firstly treated by ultrasonic cleaning with acetone, alcohol and deionized water, and dried in a vacuum oven at 180° C. for 3 hours. Then spin-coat polydimethylsiloxane 2 with a thickness of 500 μm on the substrate at a speed of 500 rpm, and cure at 90° C. for 3 hours, then spin-coat polyimide acid with a thickness of 100 μm at a speed of 500 rpm. The flexible base polyimide 3 is formed by thermal curing by a stepwise heating method (from 80° C. to 120° C. to 180° C. to 280° C.).

[0043] (2) Fabrication of metal circuits

[0044] First, sputter 150nm Cr / Cu metal base film 4 on the surface of flexible substrate polyimide 3, spin-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com