Stirling cooling storage

A technology of cooling storage and refrigerant, applied in the field of Stirling cooling storage, can solve the problems of noise piping damage, etc., and achieve the effect of preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

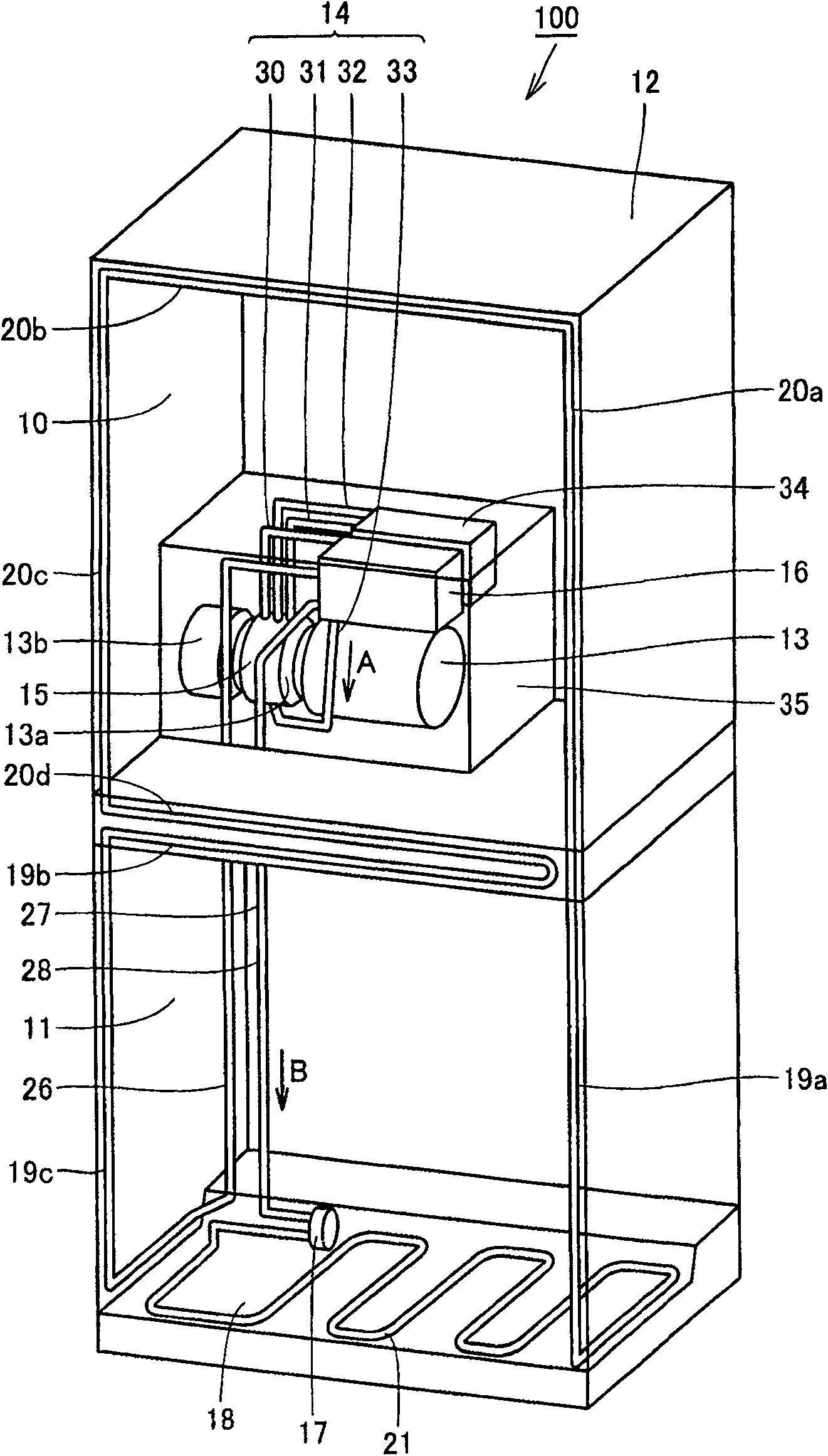

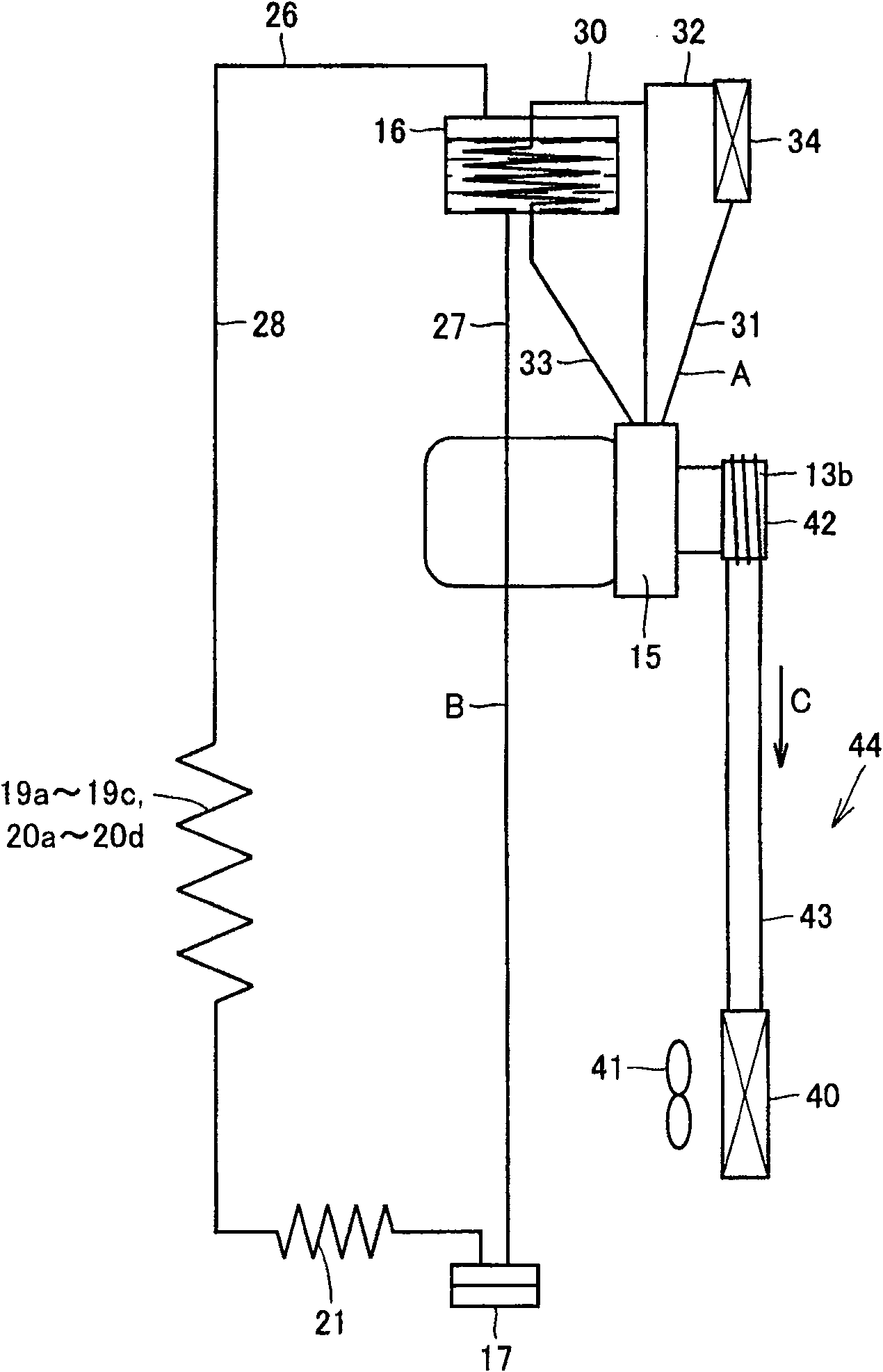

[0027] figure 1 It is a perspective view showing a schematic structure of the Stirling cooler 100 according to Embodiment 1 of the present invention, as shown in figure 1 As shown, the Stirling cooler 100 has: a refrigerator compartment (cooling compartment) 10 for accommodating an object to be refrigerated (object to be cooled); a freezer compartment ( cooling compartment) 11; a casing (partition wall) 12 made of a heat insulating material that divides the freezing compartment 11 and the refrigerating compartment 10; and a Stirling refrigerator 13 including a heat dissipation portion 13a and a heat absorption portion 13b. In addition, the Stirling cooler 100 also has: a secondary refrigerant circulation circuit 14 in which the heat supply medium (secondary refrigerant) A naturally circulates; an evaporator 15 that evaporates the heat medium A to cool the heat dissipation portion 13a; The tertiary refrigerant circulation circuit 28 through which the heating medium (tertiary r...

Embodiment approach 2

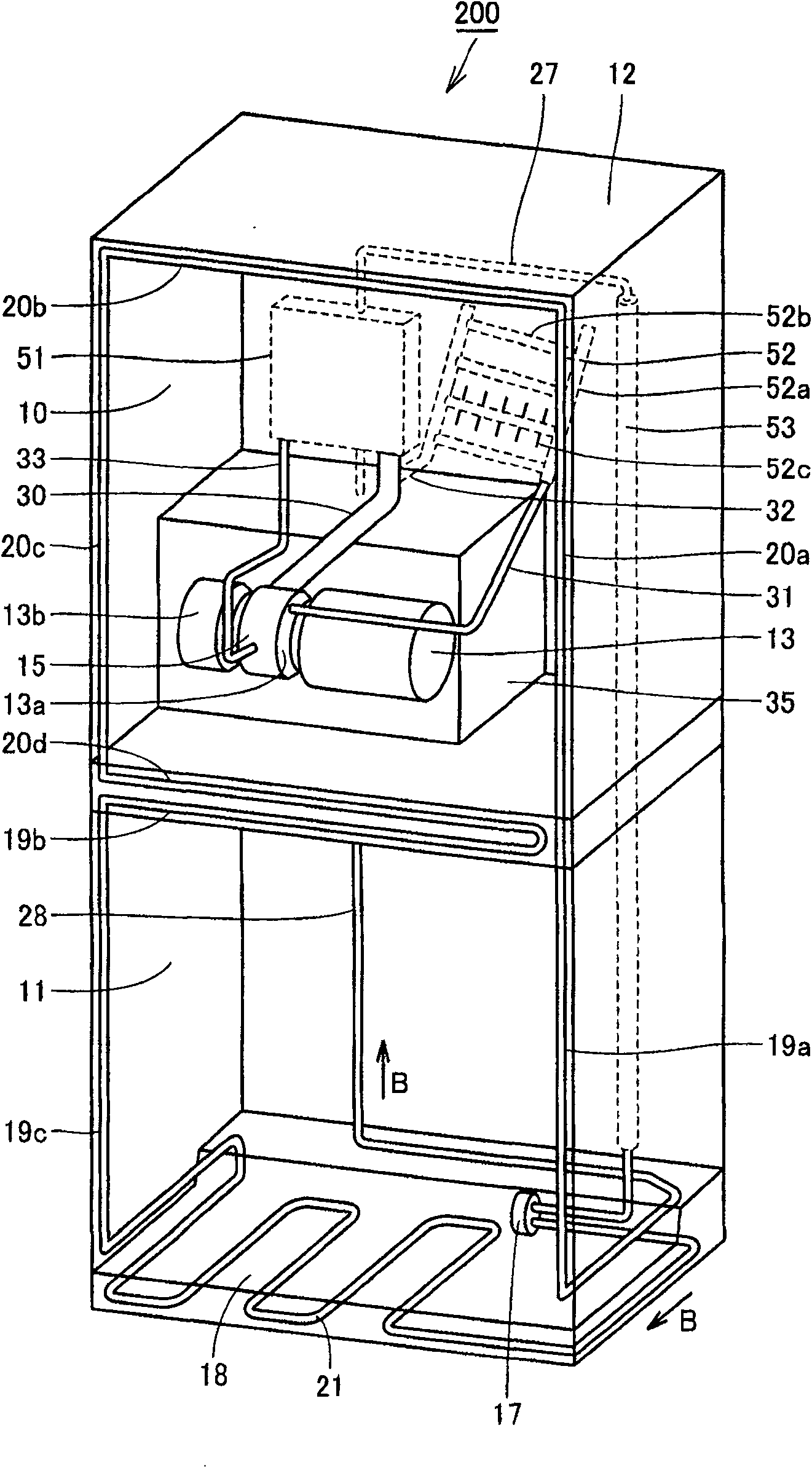

[0043] combine Figure 3 to Figure 5 Embodiment 2 of the present invention will be described. image 3 It is a perspective view of the Stirling cooler 200 of the second embodiment, as image 3 As shown, the heat exchanger 51 and the condenser 52 are installed on the rear side of the Stirling cooler 200 . In addition, suction tank 53 is provided on one side of the back side of Stirling cooler 200 . The suction tank 53 is configured in a columnar shape, extends from the upper surface side toward the lower surface side of the Stirling cooler 200 , and is embedded in the casing 12 made of a heat insulating material.

[0044] In addition, the suction tank 53 has a larger diameter than the high-temperature pipe 27 and the like connected to the upper end portion of the suction tank 53 . In addition, the lower end of the suction tank 53 is located on the bottom side of the Stirling cooler 200 , and the piezoelectric pump 17 is connected to the lower end of the suction tank 53 . In...

Embodiment approach 3

[0057] combine Figure 6 Embodiment 3 of the present invention will be described. Figure 6 It is a piping system diagram of the Stirling cooler 300 according to Embodiment 3, such as Figure 6As shown, the evaporator 15 is provided with a double-tube heat exchanger 80 having the functions of a condenser and a heat exchanger, which is arranged above the evaporator 15 . This double-tube heat exchanger 80 has an outer tube 81 and an inner tube 82 formed with a smaller diameter than the outer tube 81 and disposed inside the outer tube 81 . A plurality of cooling fins 83 are provided on the outer peripheral surface of the outer tube 81 . In addition, the secondary refrigerant circulation circuit 14 is connected between the outer pipe 81 and the inner pipe 82 , and the tertiary refrigerant circulation circuit 28 is connected to the inner pipe 82 . That is, between the outer tube 81 and the inner tube 82 at the upper end of the double-tube heat exchanger 80, the gas tube 30 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com