Liquid ejecting apparatus and control method thereof

一种喷射装置、液体喷射头的技术,应用在打印装置、印刷等方向,能够解决喷射不良、压力室变形、气泡滞留等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

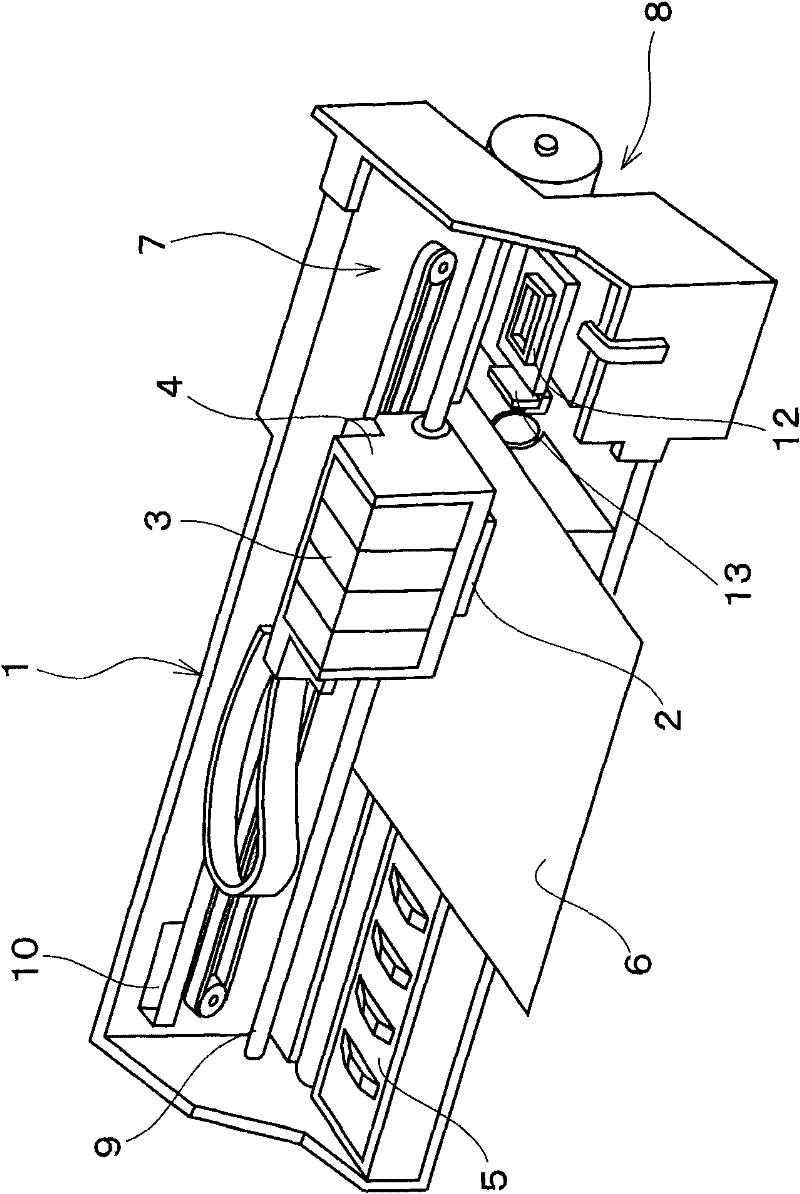

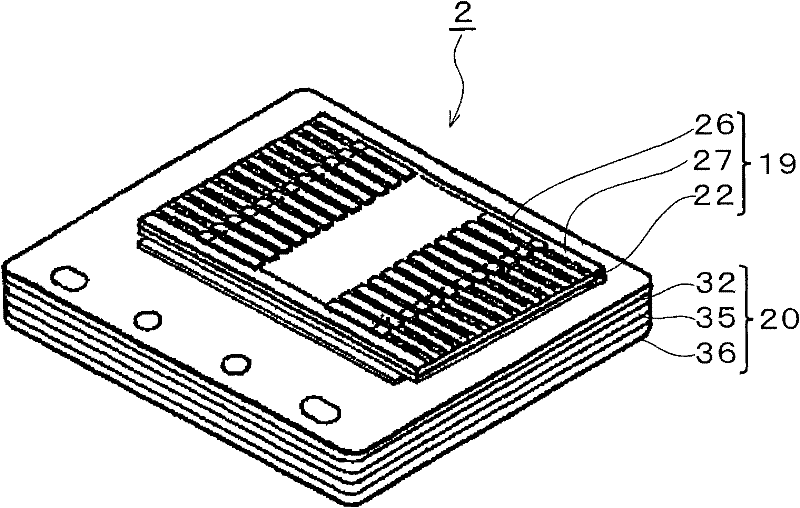

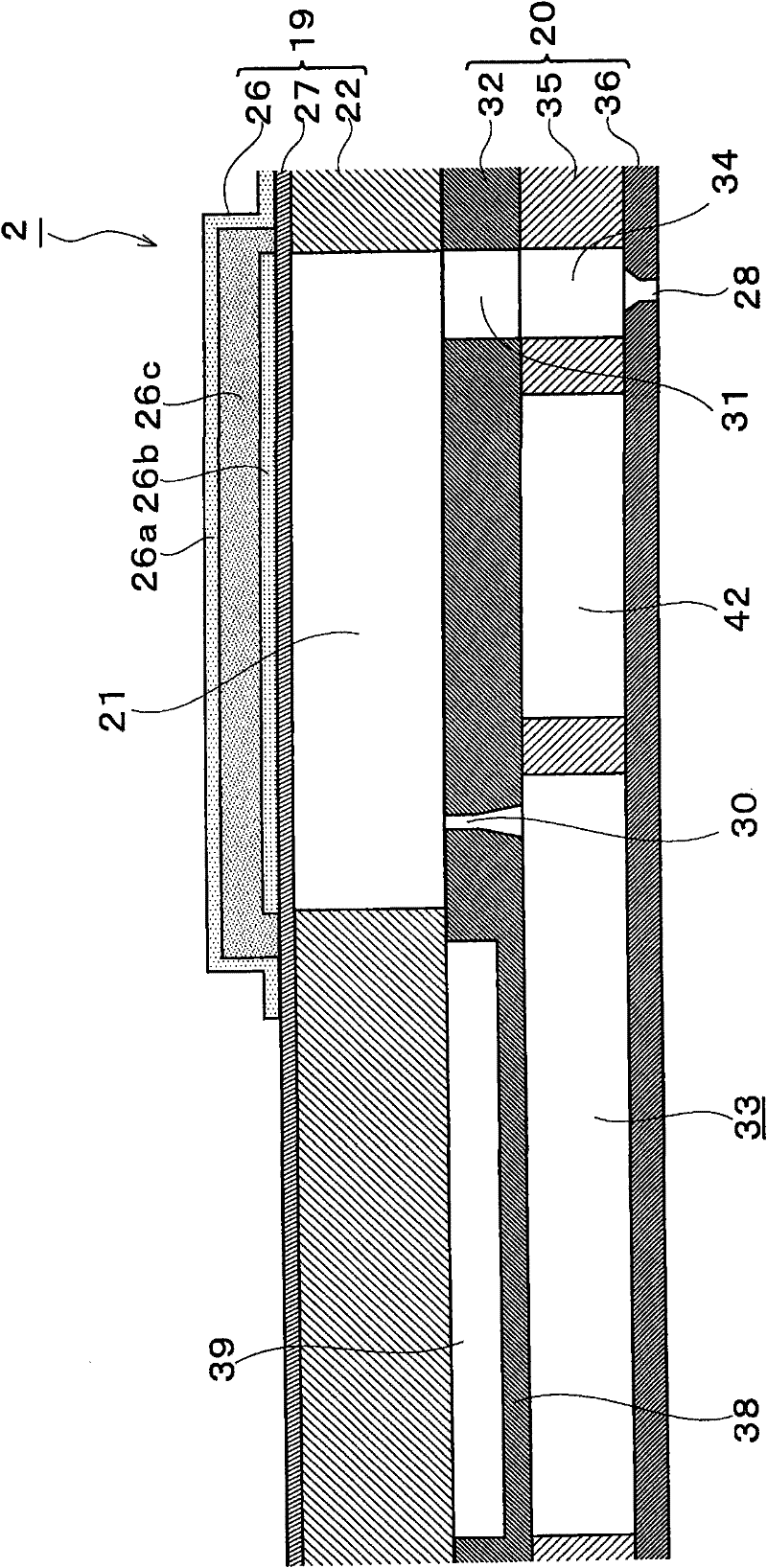

[0025]Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings. In addition, in the embodiments described below, although various limitations were made as preferred specific examples of the present invention, the scope of the present invention is not limited to these ways. In addition, hereinafter, as the liquid ejecting device of the present invention, examples applied to figure 1 The case of the inkjet type recording apparatus (hereinafter simply referred to as a printer) is shown.

[0026] A printer 1 is schematically configured with the following components: a recording head 2 as a type of liquid ejection head is mounted and an ink cartridge 3 (a liquid in the present invention) that stores ink (a type of liquid in the present invention) can be detachably mounted. a type of cartridge), a platen 5 arranged below the recording head 2, and the carriage 4 on which the recording head 2 is mounted moves in the paper wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com