Piston ring and method for producing the same

A technology for piston rings and coatings, which is applied to piston rings, machines/engines, mechanical equipment, etc. It can solve the problems of not being able to reach the contact state near the seam, the life of the polishing sleeve is short, and it takes a long time to polish, so as to achieve film formation. The effect of short time, low cost, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described in detail.

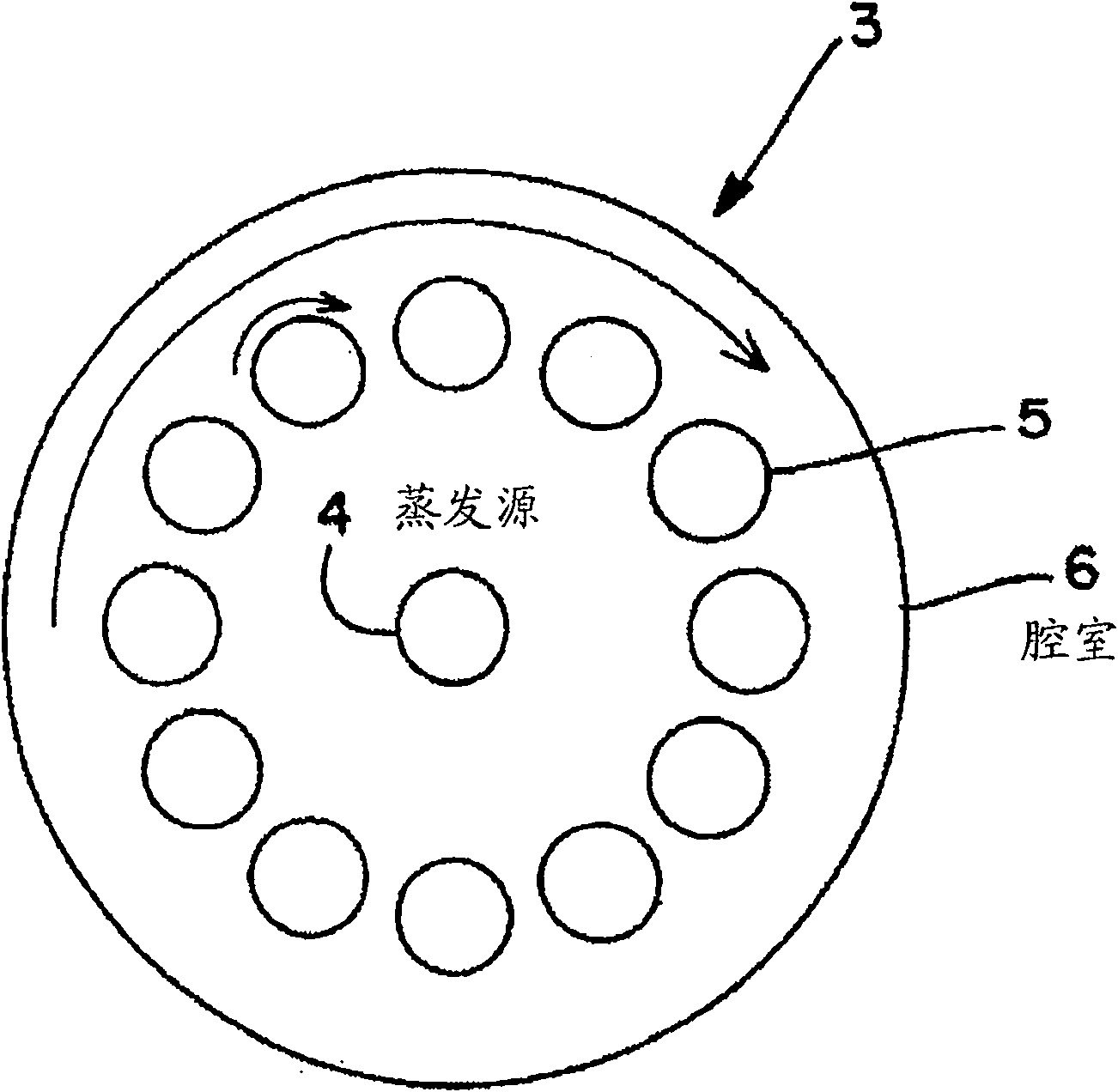

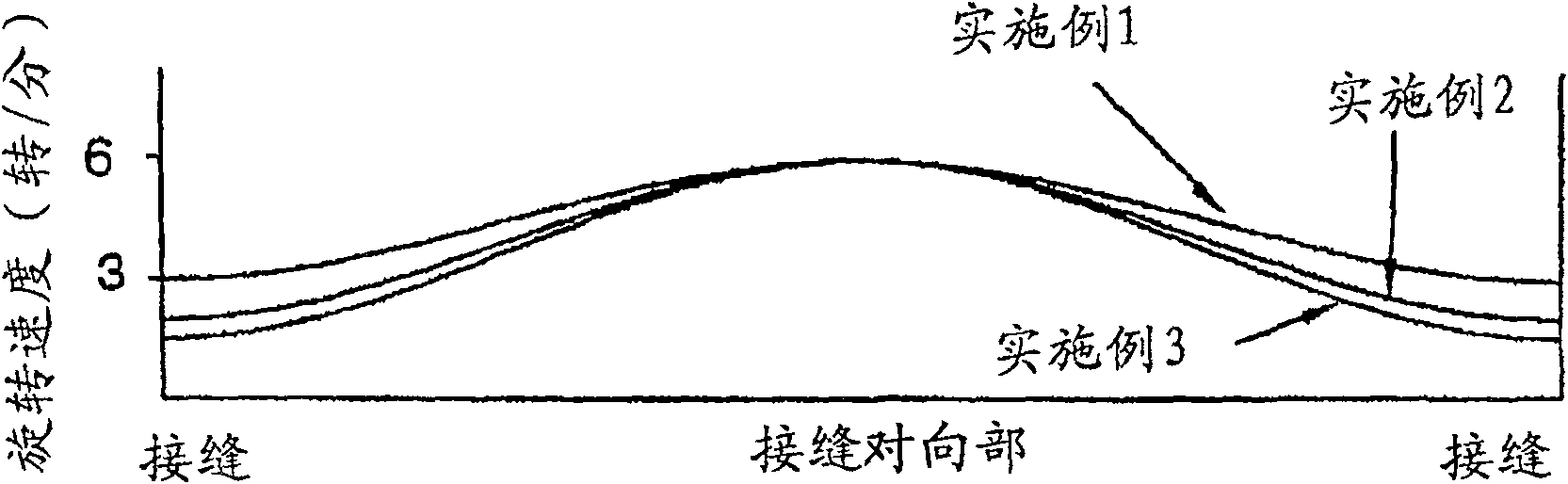

[0036] figure 1 , Is a piston ring showing an example of the present invention. In the figure, (a) is a plan view of the piston ring 1 as viewed from the axial direction, (b) is a radial cross-sectional view of the opposite part of the joint of the piston ring 1, and A represents the thickness of the piston ring coating 2. (c) is a cross-sectional view showing the vicinity of the joint in the radial direction, and B is the thickness of the piston ring coating 2. (c) shows a cross-sectional view in the radial direction near the joint, and B is the thickness of the piston ring coating 2.

[0037] Hereinafter, a representative manufacturing process of the above-mentioned piston ring will be described.

[0038] First, by winding any steel wire rods of various cross-sectional shapes, they are formed into the approximate shape of a piston ring. The shape of the outer peripheral surface at this time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com