Flow guide plate, mashing assembly and cooking utensil

A technology of cooking utensils and deflectors, which is applied in the field of household appliances, can solve problems such as poor crushing effect, complex structure, and difficult cleaning of products, and achieve the effects of improving crushing effect, improving diversion effect, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

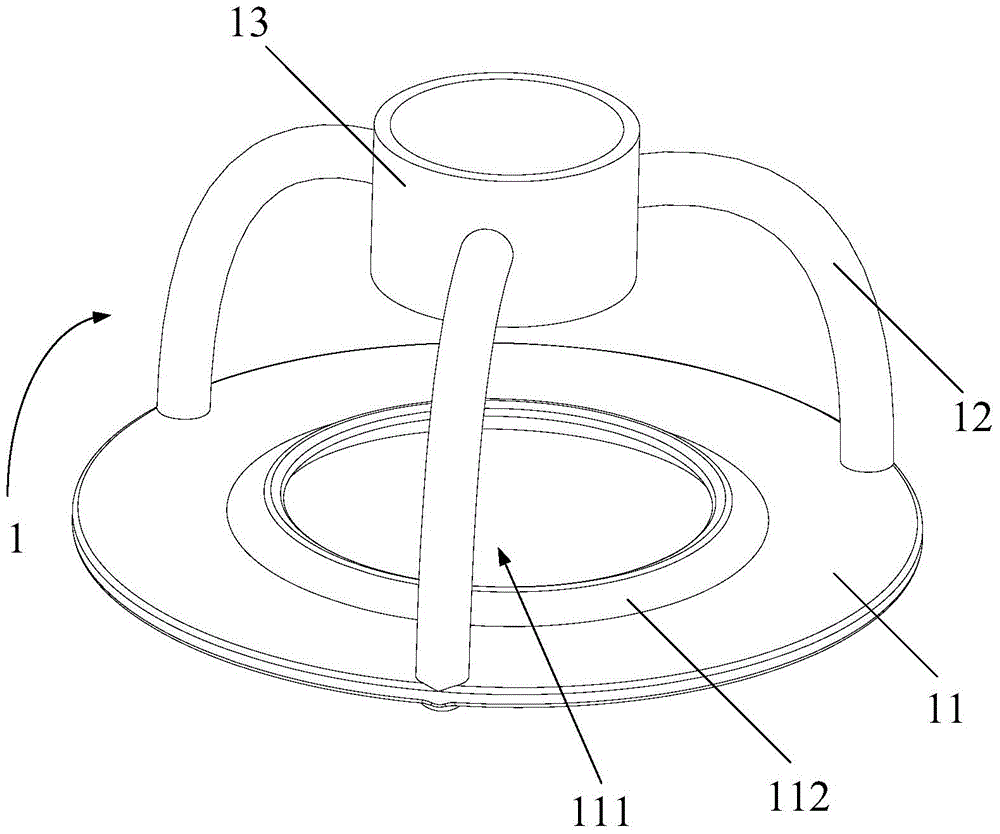

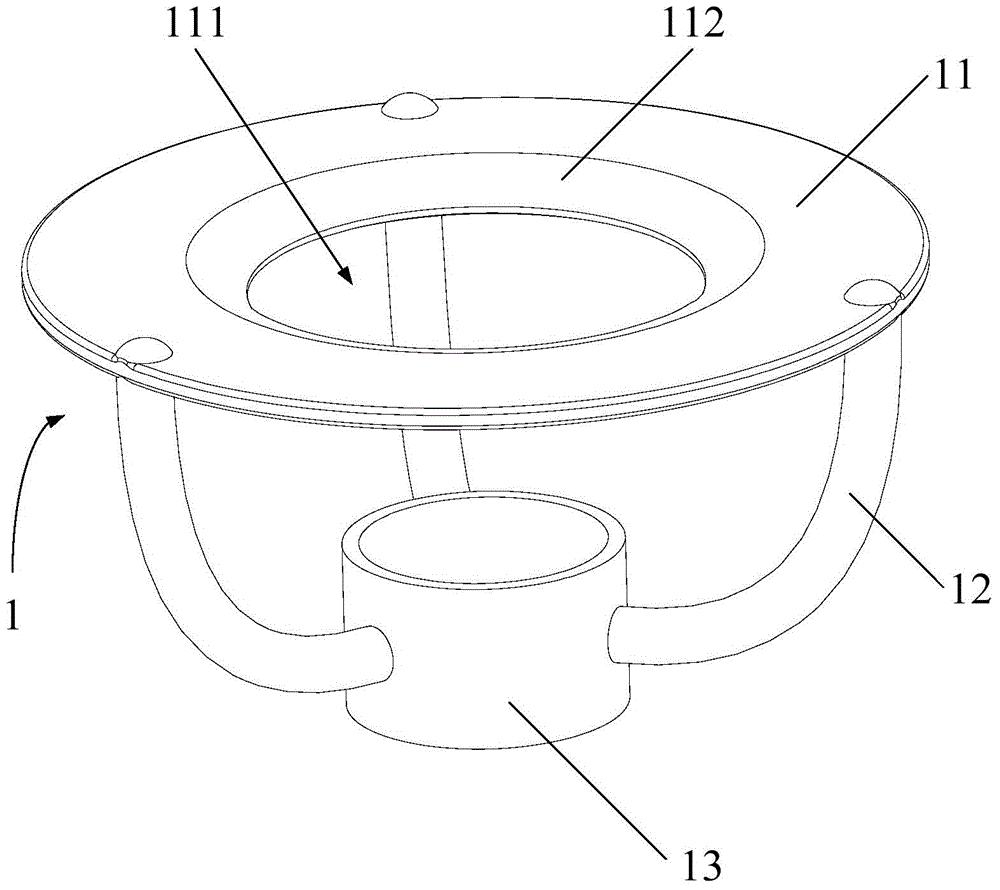

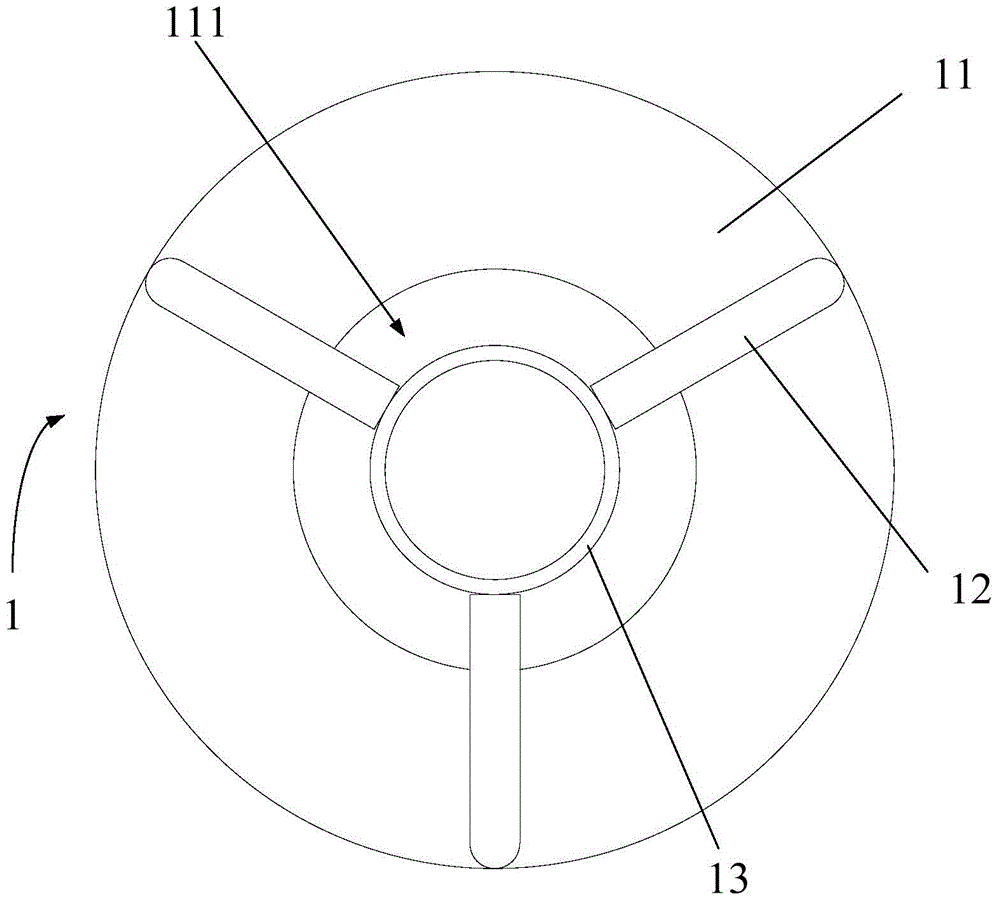

[0103] Such as Figure 1A to Figure 2 As shown, the deflector plate 1 includes a chassis 11 provided with a feeding hole 111, three connecting bodies 12 and a connecting piece 31, wherein the connecting bodies 12 are curved connecting rods, and the first ends of the three curved connecting rods are connected to the chassis respectively. 11 and the second end are respectively connected to the connecting piece 31 , and the deflector plate 1 is connected to the main body 3 of the cooking appliance through the connecting piece 31 .

Embodiment 2

[0105] Such as Figure 3A to Figure 4 As shown, the deflector plate 1 includes a chassis 11 with feed holes 111, four connecting bodies 12 and connecting parts 31, wherein the connecting bodies 12 are straight connecting rods, and the connecting parts 31 include a fixed plate 131 and an interface for fixed connection. In the component 132 , the first ends of the three straight connecting rods are respectively connected to the chassis 11 , and the second ends are respectively connected to the fixing plate 131 , and the deflector plate 1 is connected to the main body 3 of the cooking appliance through the interface component 132 .

[0106] According to an embodiment of the present invention, the area of the feeding hole 111 ranges from 200 square millimeters to 11000 square millimeters, wherein the preferred range is 700 square millimeters to 6400 square millimeters, and the most preferred range is 1200 square millimeters to 1800 square millimeters mm.

[0107]According to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com