Flexible cantilever plate vibration control set and control method based on acceleration sensor

An acceleration sensor, cantilever plate technology, applied in mechanical oscillation control, non-electric variable control, measurement devices and other directions, can solve the performance impact, large amount of calculation, difficult to control residual vibration and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention is not limited to the scope expressed by the examples.

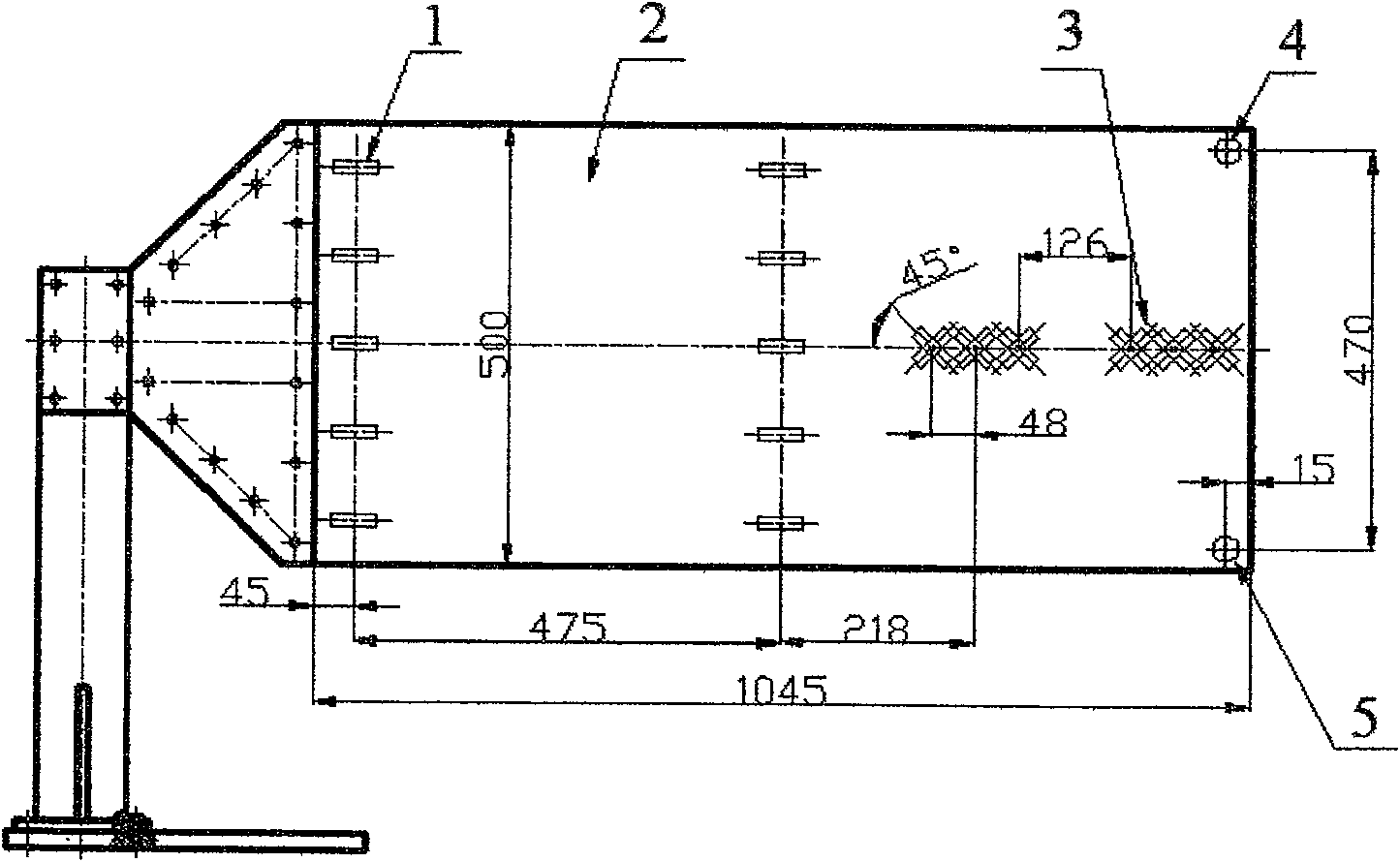

[0047] like figure 1 , 2, the vibration control device for a flexible cantilever plate based on an acceleration sensor includes a mechanical support clamping device 14, a flexible plate 2, a bending mode piezoelectric driver 1, a torsional mode driver 3, one of the acceleration sensors 4, an acceleration Sensor 2 5, extremely low frequency charge amplifier 7, multi-channel A / D conversion data acquisition card 8, computer 9, multi-channel D / A conversion card 10, multi-channel piezoelectric ceramic power supply 11, arbitrary function signal generator 12 and liquid crystal Display 13.

[0048] The clamping device 14 of the mechanical support is mainly composed of a flat rectangular base plate, a rectangular column bracket and an isosceles trapezoidal spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com