Fast slip casting technique between composite well wall

A technology of grouting system and shaft wall, which is applied in the direction of sinking, shaft equipment, mining equipment, etc., can solve the problems of poor safety conditions, small space, low efficiency, etc., and achieve fast grouting speed, prevent water leakage, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

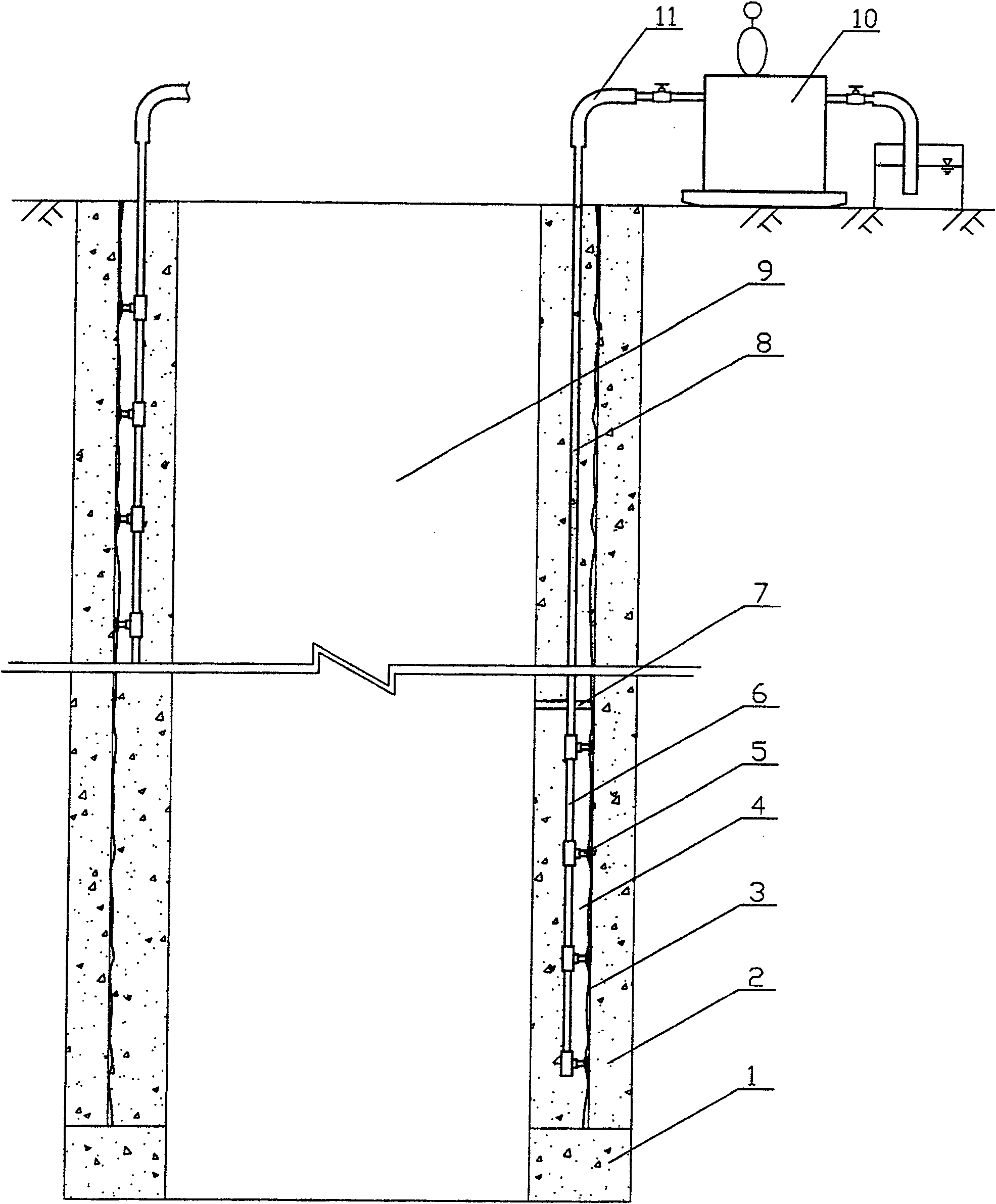

[0011] Depend on figure 1 As shown, the composite well wall is composed of the outer well wall 2, the inner well wall 4, and the plastic interlayer wall 3. The grouting pump 10 is fixed on the surface of the wellhead. Before grouting, the wellbore is segmented according to the depth of the frozen wellbore, the thickness of the well wall, the strength, and the level of the aquifer. Generally, the wellbore is divided into 1-4 grouting segments. The section height is generally 100-200m. When constructing the inner shaft wall 4, the vertical section grouting pipe 6 suitable for the height of the grouting section is preset and pre-embedded, and the section grouting pipe 6 is set inside In the well wall of each layer, the preset and pre-embedded vertical segmented grouting pipes are sequentially carried out upwards from above the wall seat 1. A number of grouting heads 5 are arranged on the segmented grouting pipe 6, and the distance between the grouting heads 5 is 5-7 meters. The ...

Embodiment 2

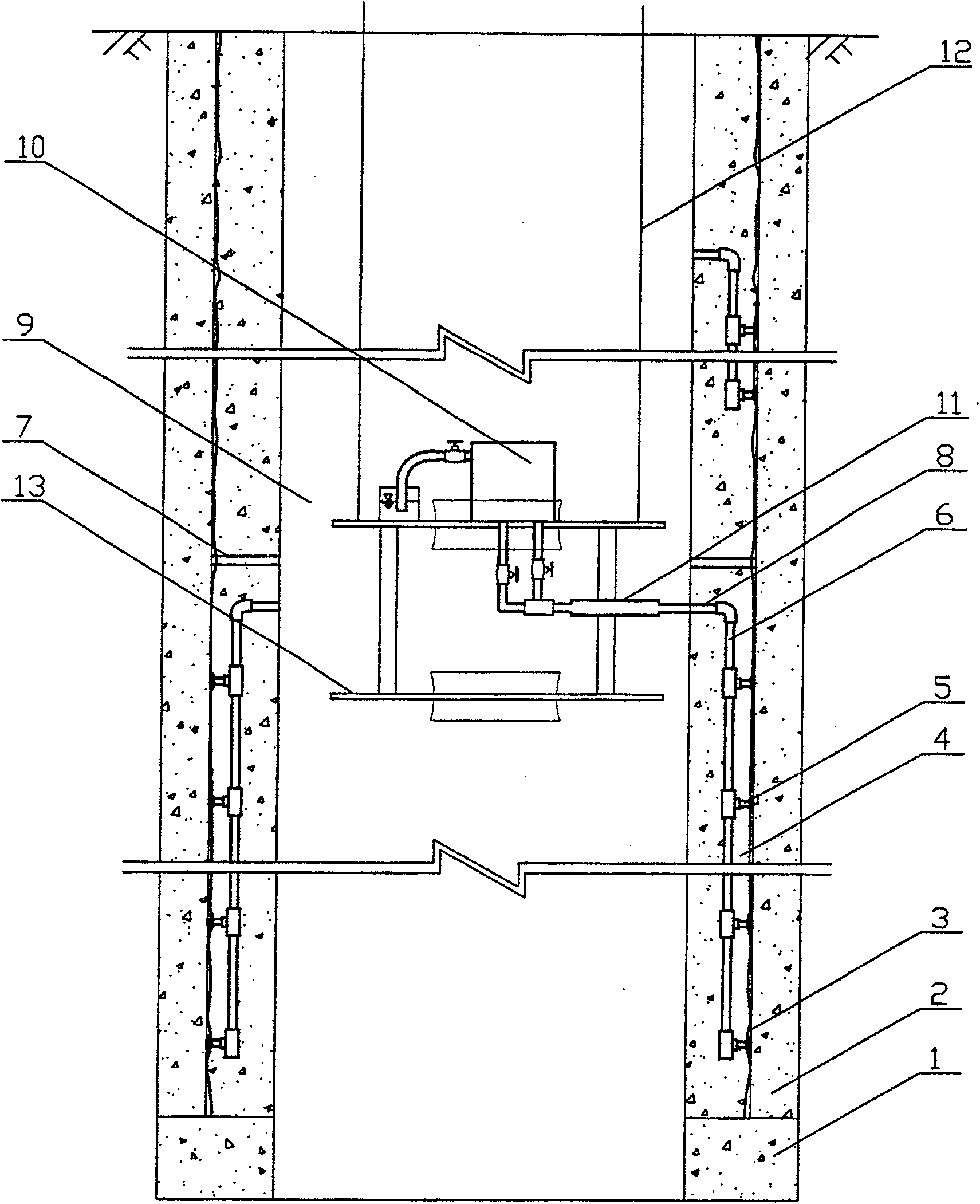

[0013] Depend on figure 2 As shown, the composite well wall is composed of the outer well wall 2, the inner well wall 4, and the plastic interlayer wall 3. The grouting pump 10 is fixed on the hanging pan 13 in the wellbore 9, and the hanging pan 13 is pulled by four hanging pan wire ropes 12. Slurry segmentation, generally divide the wellbore into 2-3 grouting segments, and the segment height is generally 100-200m. When constructing the inner well wall 4, the preset, pre-embedded and grouting segment heights are suitable The vertical segmental grouting pipe 6 is arranged in the inner shaft wall 4, and the vertical segmental grouting pipes are preset and pre-embedded starting from above the wall seat 1 and proceeding upwards sequentially. A plurality of grouting heads 5 are arranged on the segmented grouting pipe 6, and the distance between the grouting heads is 5-7 meters. The grouting heads 5 communicate with the plastic interlayer walls 3, and multiple grouting points are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com