On-line testing device of carbon content in flying ashes in boiler flue for coal power station

A technology for the carbon content of fly ash and boiler flue, which is applied to the sampling device, the preparation of test samples, and the weighing by removing certain components, and can solve the problems that the microwave carbon measurement technology is affected by the change of coal types, etc. , to achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

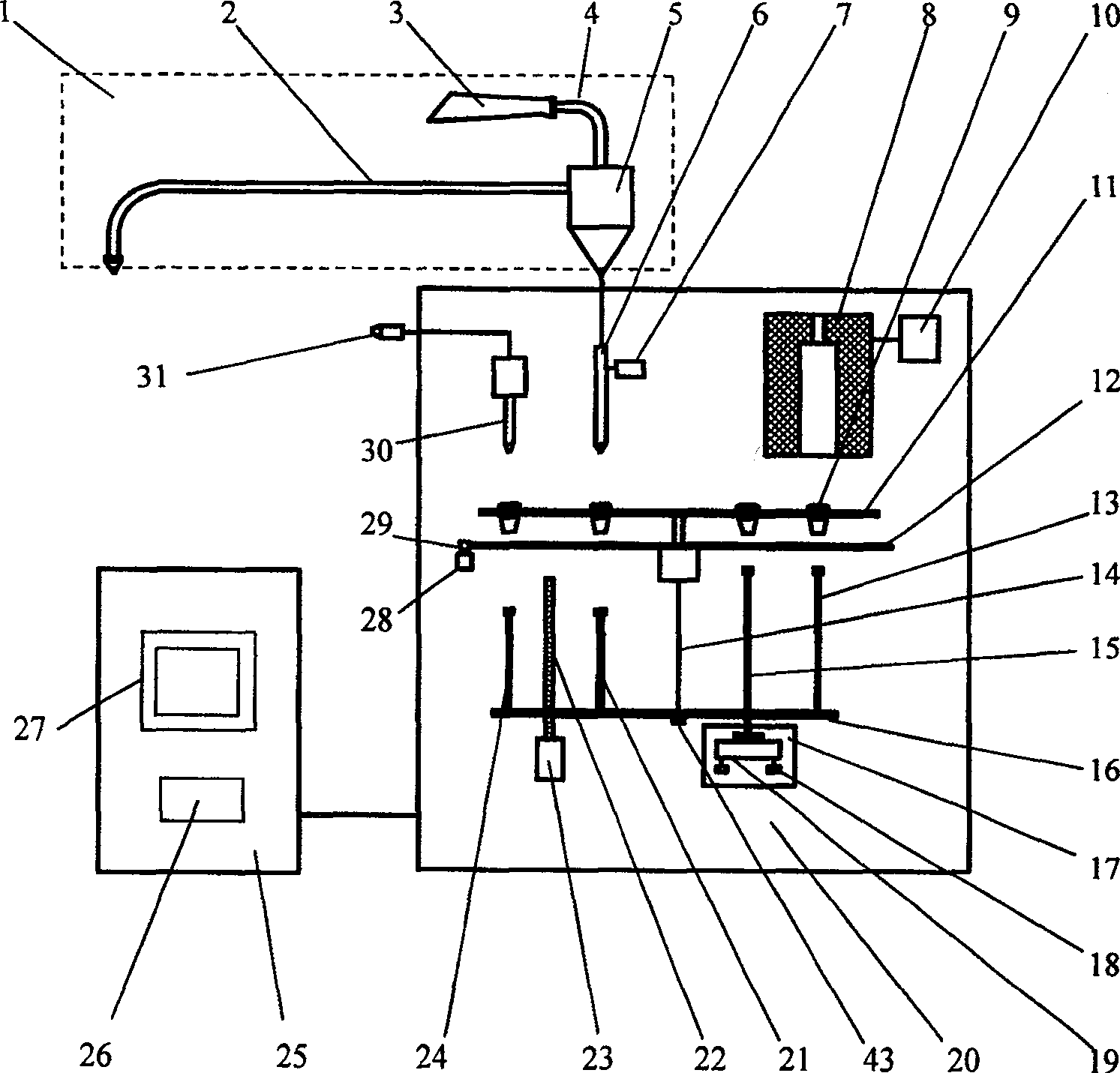

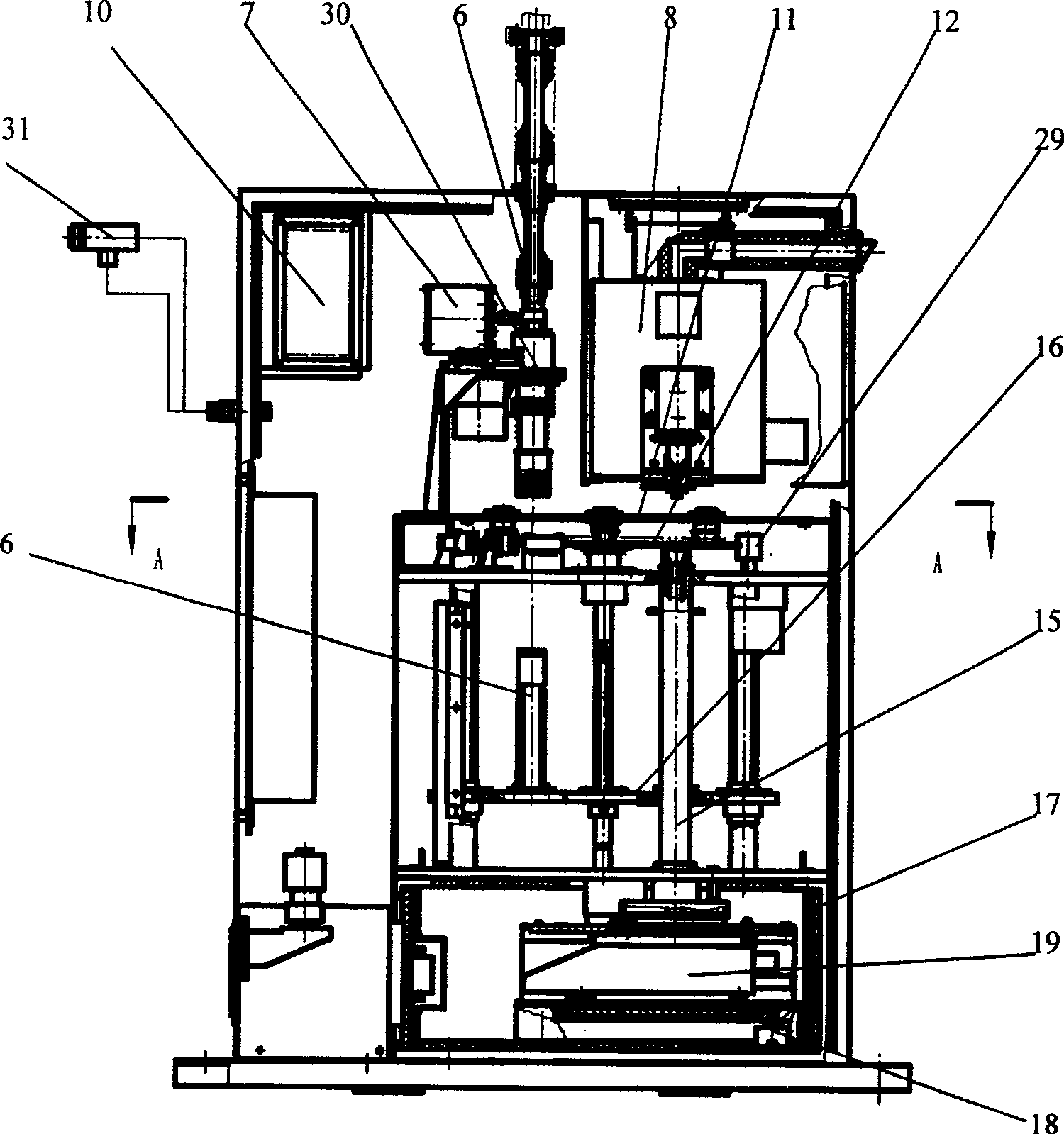

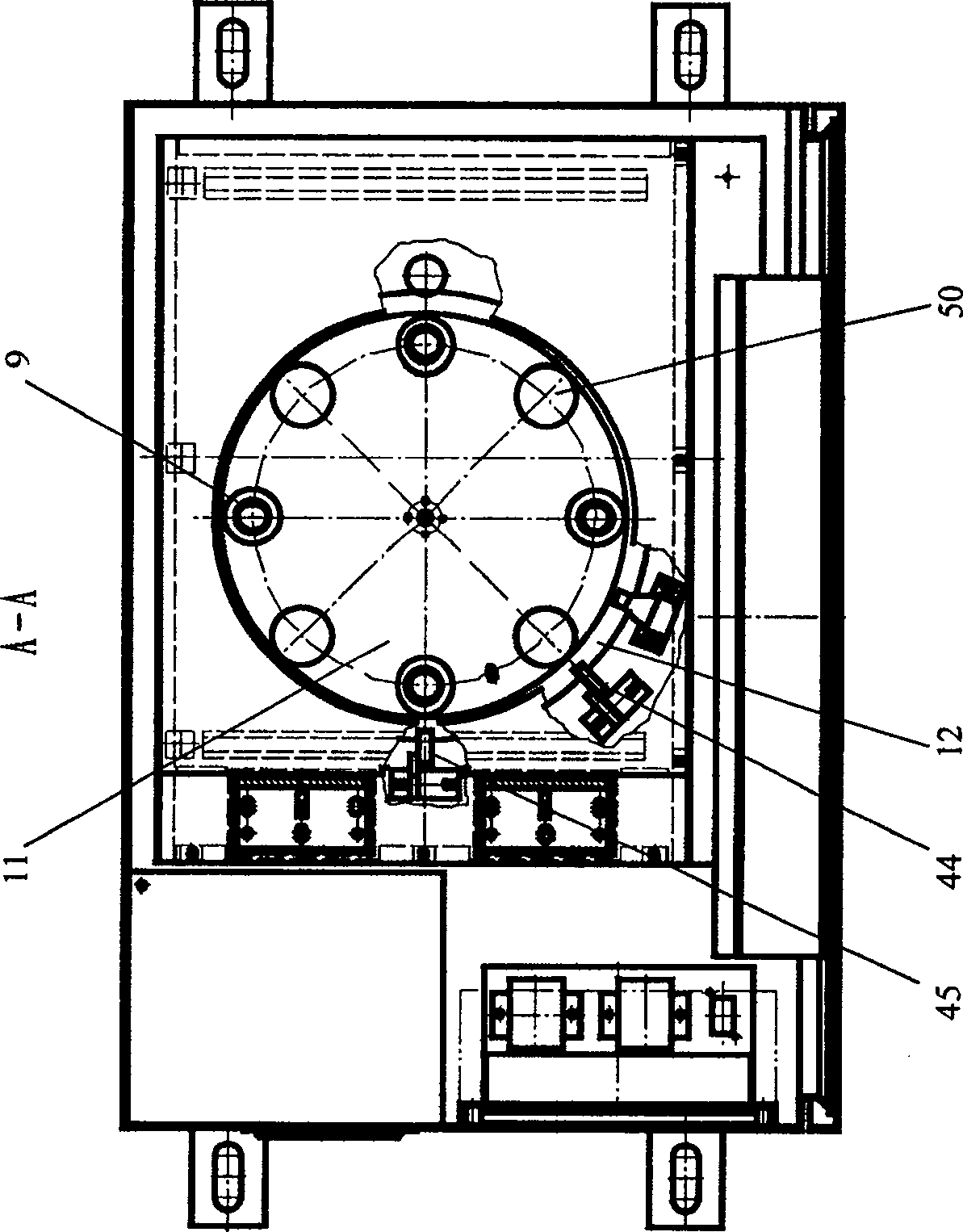

[0023] Such as figure 1 , 2 , 3, 4, and 5. An on-line detection device for carbon content in fly ash of coal-fired power station boiler flue based on weightlessness technology, which consists of a sampler 1 installed on the wall of the flue, a measurement box 20 and a control box 25 installed below the sampler 1 .

[0024] The sampler 1 is composed of a sampling pipe 2 , a cyclone dust collector 5 , an injection elbow 4 and an injection pipe 3 .

[0025] The measuring box 20 is composed of an ash feeding pipe 6 connected to the lower port of the cyclone dust collector 5, a vibrator 7 installed on the mounting frame 42 of the ash feeding pipe 6, and an electric furnace for burning the ash sample. 8. A temperature controller 10 for controlling the temperature of the electric furnace 8, a turntable 11 for placing the loaded crucible 9 on hold, and four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com