Method for preparing sewage water additive by intermediate product of diatomite purification

A technology of sewage treatment agent and diatomite refined soil, applied in adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, chemical instruments and methods, etc., can solve problems such as pollution and threat to the ecological environment, and reduce environmental pollution , High adsorption efficiency, and the effect of improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Take diatomite and waste acid liquid with a silicon dioxide content of 60% associated with sulfuric acid pickling and purification of high-burn vector diatom concentrate, and mix diatomite into the waste according to the solid-to-liquid volume ratio of 1:20. In the acid solution, stir to form a slurry, heat at 90°C for 4 hours, immerse and cool for 3 hours; dissolve hexadecyltrimethylammonium bromide in water to prepare a solution with a concentration of 1.35wt% by weight, and use Sodium hydroxide adjusts the pH of the solution to 9; pour the solution into diatomaceous earth and waste acid liquid cooling material, stir and impregnate for 10 hours, filter and obtain a diatomite filter cake, and then place the filter cake in a muffle at a temperature of 150°C After roasting in the furnace for 1 hour, it was pulverized, and the product was collected by sieving.

Embodiment 2

[0016] Example 2: Take the diatomite and waste acid liquid with a silicon dioxide content of 50% associated in the process of sulfuric acid pickling and purification of high-burn vector diatom concentrate, and mix diatomite into the waste according to the solid-to-liquid volume ratio of 1:30. In the acid solution, stir to form a slurry, heat at 100°C for 3 hours, immerse and cool for 4 hours; dissolve hexadecyltrimethylammonium bromide in water to prepare a solution with a concentration of 1.55wt% by weight, and use Sodium hydroxide adjusts the pH of the solution to 11; pour the solution into diatomaceous earth and waste acid liquid cooling material, stir and impregnate for 12 hours, filter and obtain a diatomite filter cake, and then place the filter cake in a muffle at a temperature of 200°C After roasting in the furnace for 2 hours, it was pulverized, and the product was collected by sieving.

Embodiment 3

[0017] Example 3: Take diatomite and waste acid liquid with a silicon dioxide content of 60% associated in the process of sulfuric acid pickling and purification of high-burn vector diatom concentrate, and diatomite is mixed into the waste according to the solid-to-liquid volume ratio of 1:40. In the acid solution, stir to form a slurry, heat at 100°C for 5 hours, immerse and cool for 5 hours; dissolve hexadecyltrimethylammonium bromide in water to prepare a solution with a concentration of 1.8wt% by weight, and use Sodium hydroxide adjusts the pH of the solution to 9; pour the solution into diatomaceous earth and waste acid liquid cooling material, stir and impregnate for 15 hours, filter and obtain a diatomite filter cake, and then place the filter cake in a muffle at a temperature of 250 °C After roasting in the furnace for 0.5 hour, it was pulverized, and the product was collected by sieving.

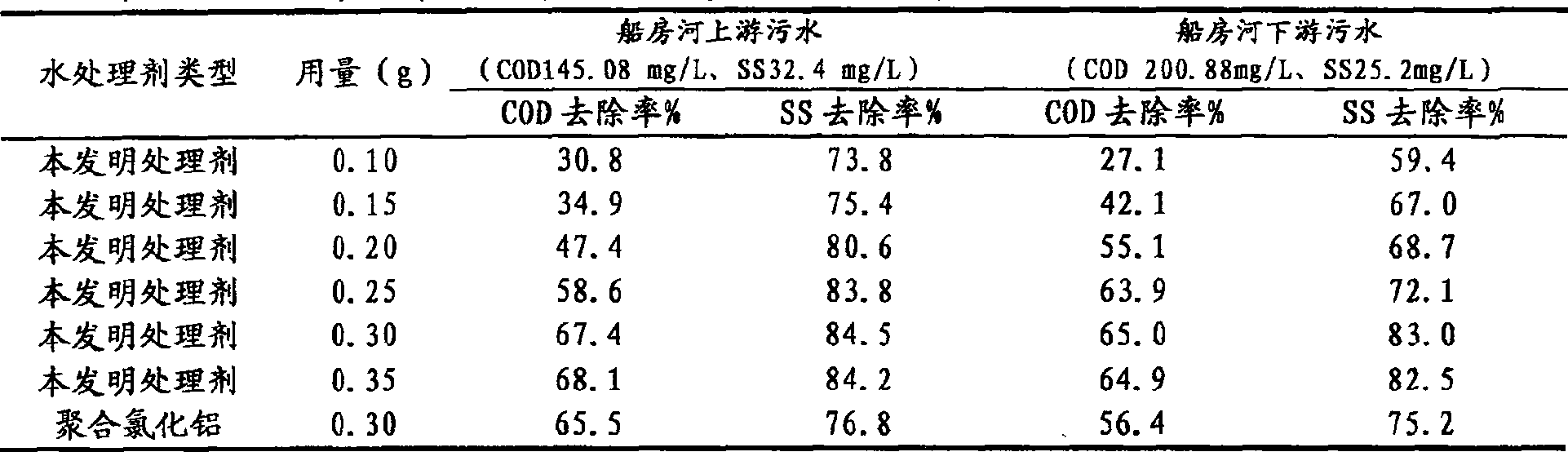

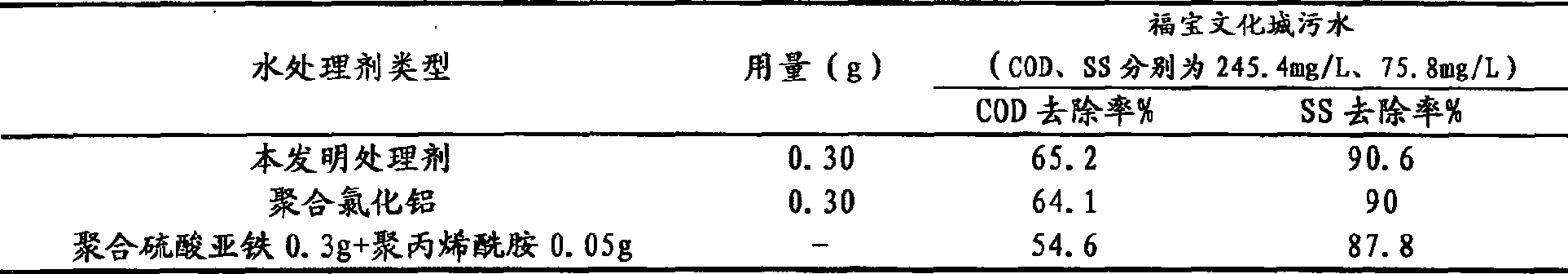

[0018] (2) The treatment agent of the present invention is used for the use met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com