Method for eliminating particles contained in exhaust gases, fibrous layer and particulate filter

A particle filter, fiber layer technology, applied in the field of fiber layer, to achieve the effect of simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

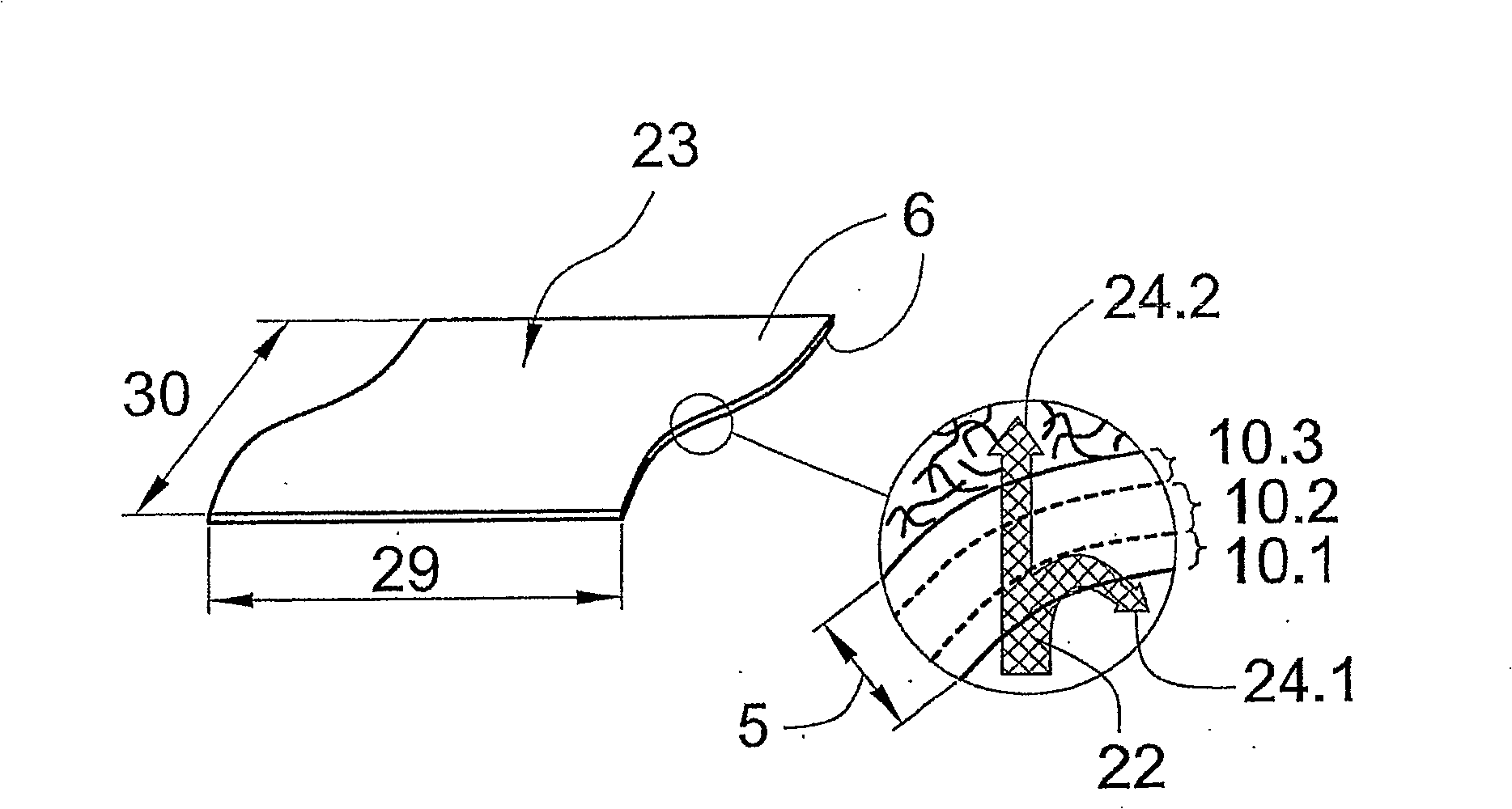

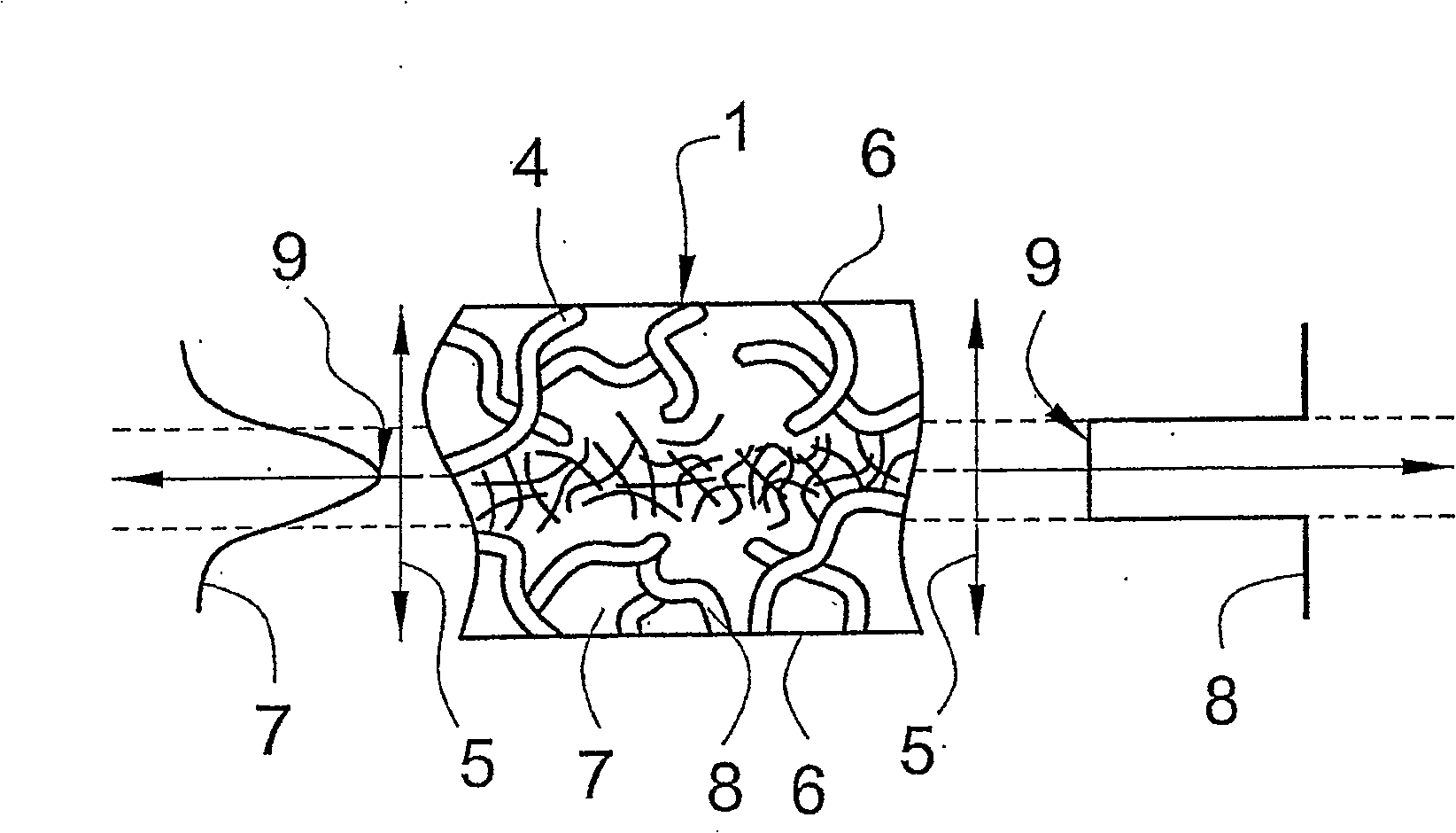

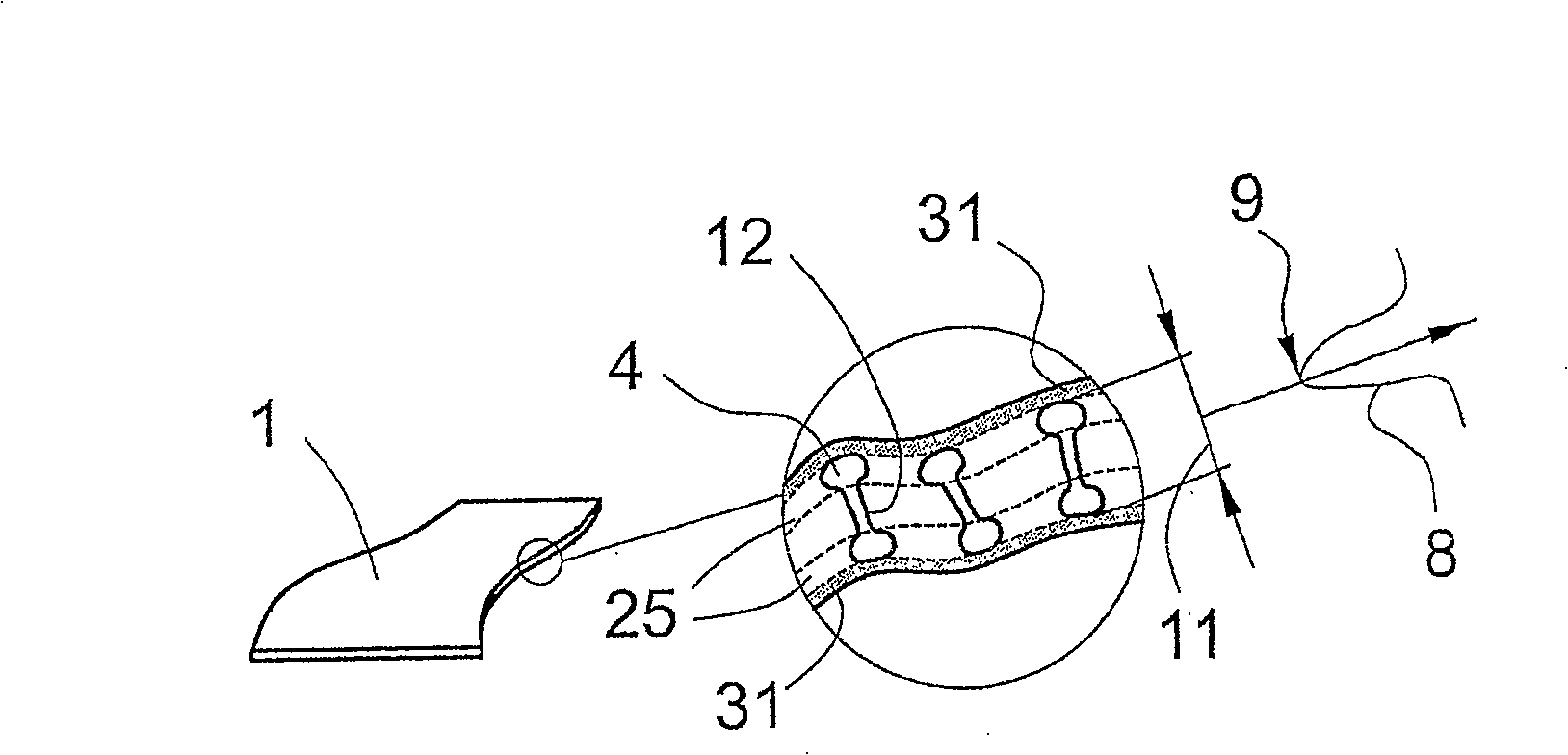

[0044] figure 1 A filter layer 23 is shown in a schematic perspective view, which is usually produced with a defined layer length 29 and layer width 30 . The filter layer 23 (or fibrous layer 1 ) is bounded by two faces 6 which ultimately define the layer thickness 5 of the filter layer 23 . In the direction of the layer thickness 5 , the air-permeable filter layer 23 has a plurality of subregions 10 ( 10 . 1 , 10 . 2 , 10 . 3 ), which differ with respect to the parameters describing the filter layer 23 . If the filter layer 23 is designed as a fiber layer 1 , characteristic parameters of the filter layer 23 include, for example, the porosity 7 or the diameter 8 of the fibers 4 .

[0045]As can be seen from the partial view, the air flow 22 emerging on the filter layer 23 is partially squeezed into the inner region of the filter layer 23 . After the entire air flow 22 has flowed through the first subregion 10.1, it reaches the second subregion 10.2. The second subregion 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com