Anti-impact LVT floor structure and preparation process thereof

A technology for impact resistance and flooring, applied in the direction of floor covering, building structure, other household appliances, etc., can solve the problems of not being able to guarantee the impact resistance effect for a long time, imperfection, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

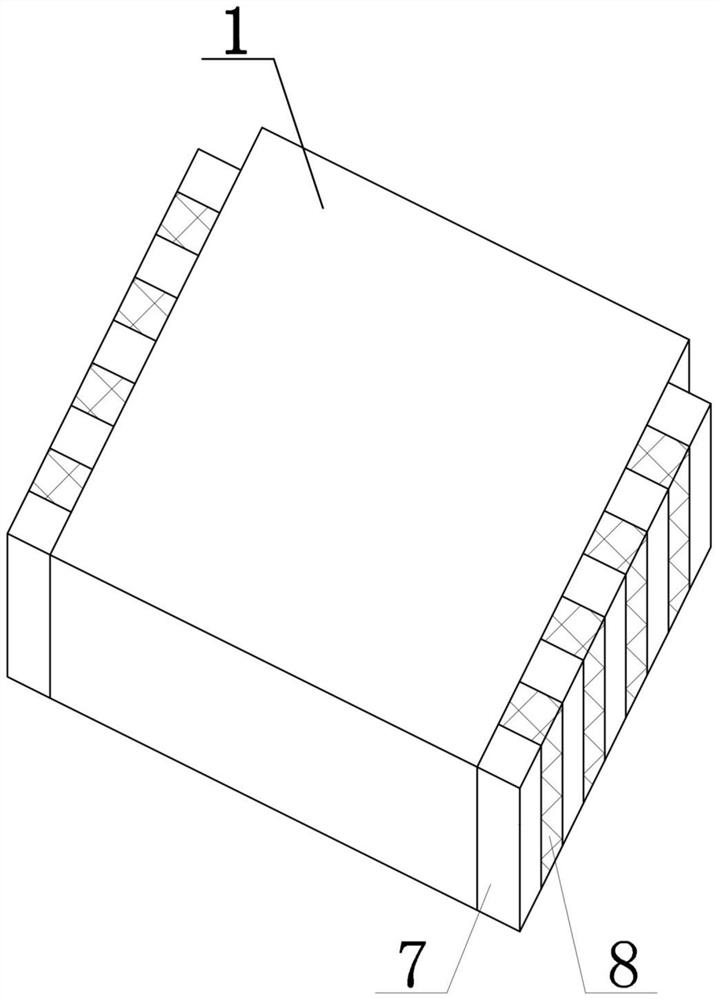

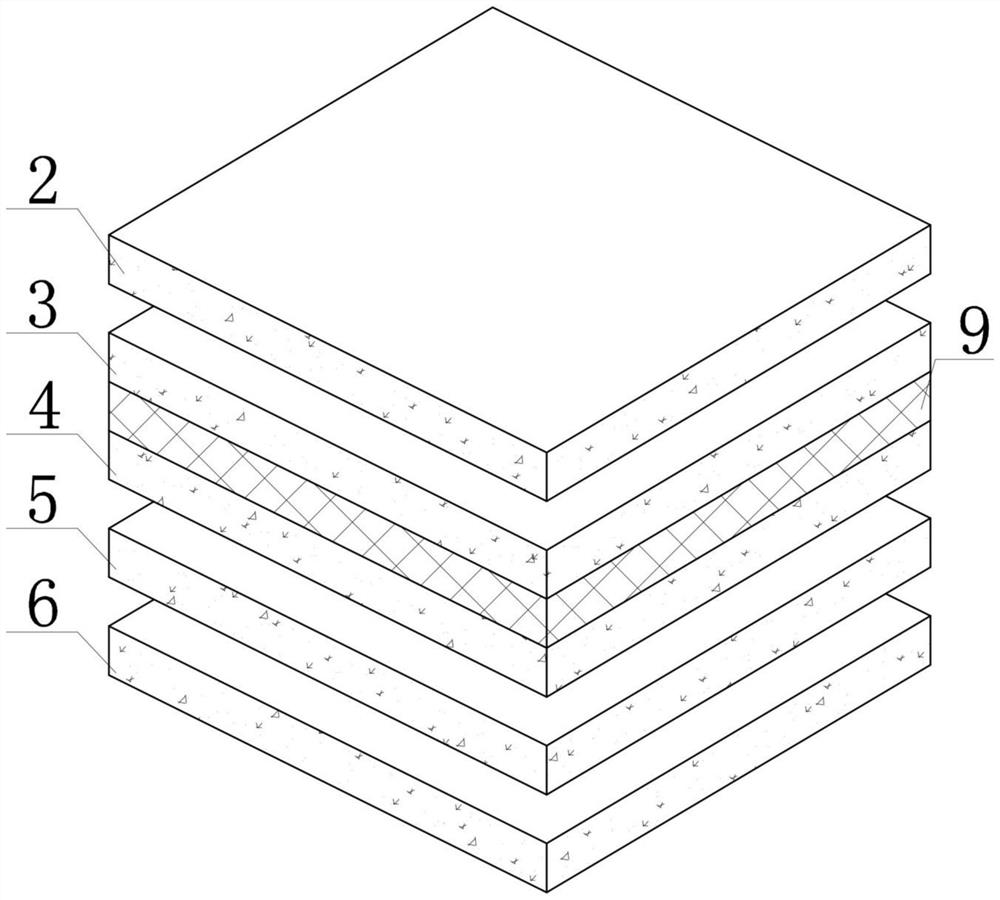

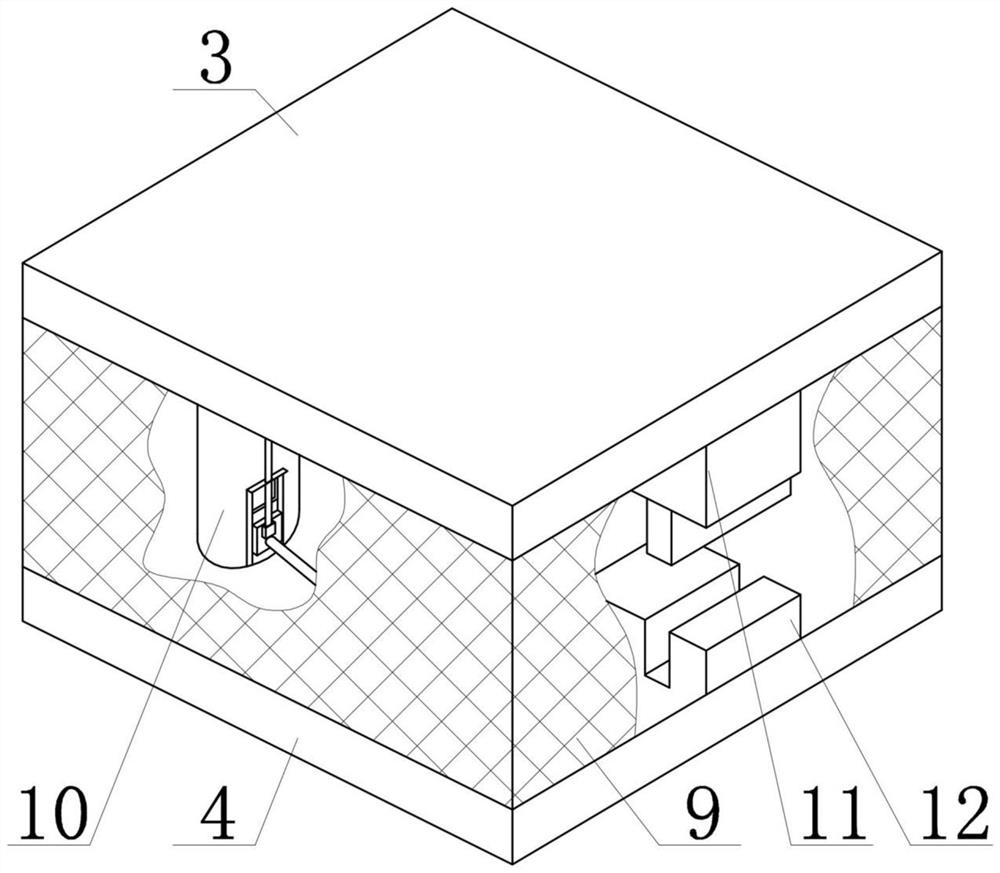

[0031] Such as figure 1 and image 3In the embodiment shown, an impact-resistant LVT floor structure includes a structural plate 1 and a ventilating plate 8. Several telescopic members 10 are installed on the structural plate 1, and several telescopic members 10 are evenly distributed inside the structural plate 1. , the top and the bottom of the telescopic member 10 are connected with the structural plate 1, the structure of the telescopic member 10 is an internal hollow structure, the telescopic member 10 is provided with a vent hole 15 and a pressing plate 14, and the pressing plate 14 matches the vent hole 15, Both the structural plate 1 and the telescopic member 10 are movably connected with the pressure plate 14, and the ventilating plate 8 includes several, and the several ventilating plates 8 are evenly distributed on the front and rear sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com