Double-stroke separation type direct-acting solenoid valve

A separate, direct-acting technology, applied in the direction of valve lift, valve detail, valve device, etc., can solve the problems of reduced life of solenoid valve, seal failure, increased distance, etc., to achieve the effect of improving service life and avoiding excessive compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

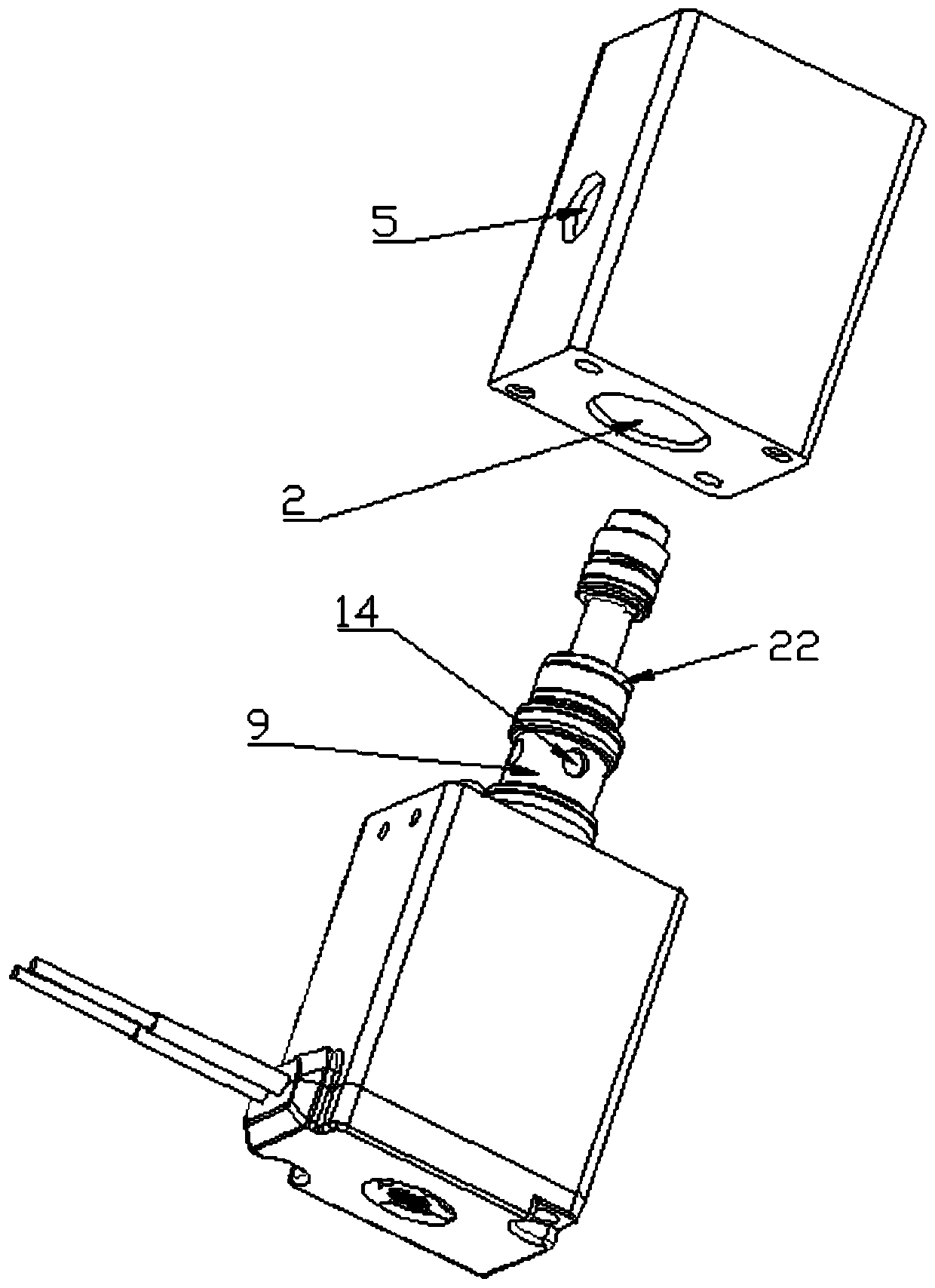

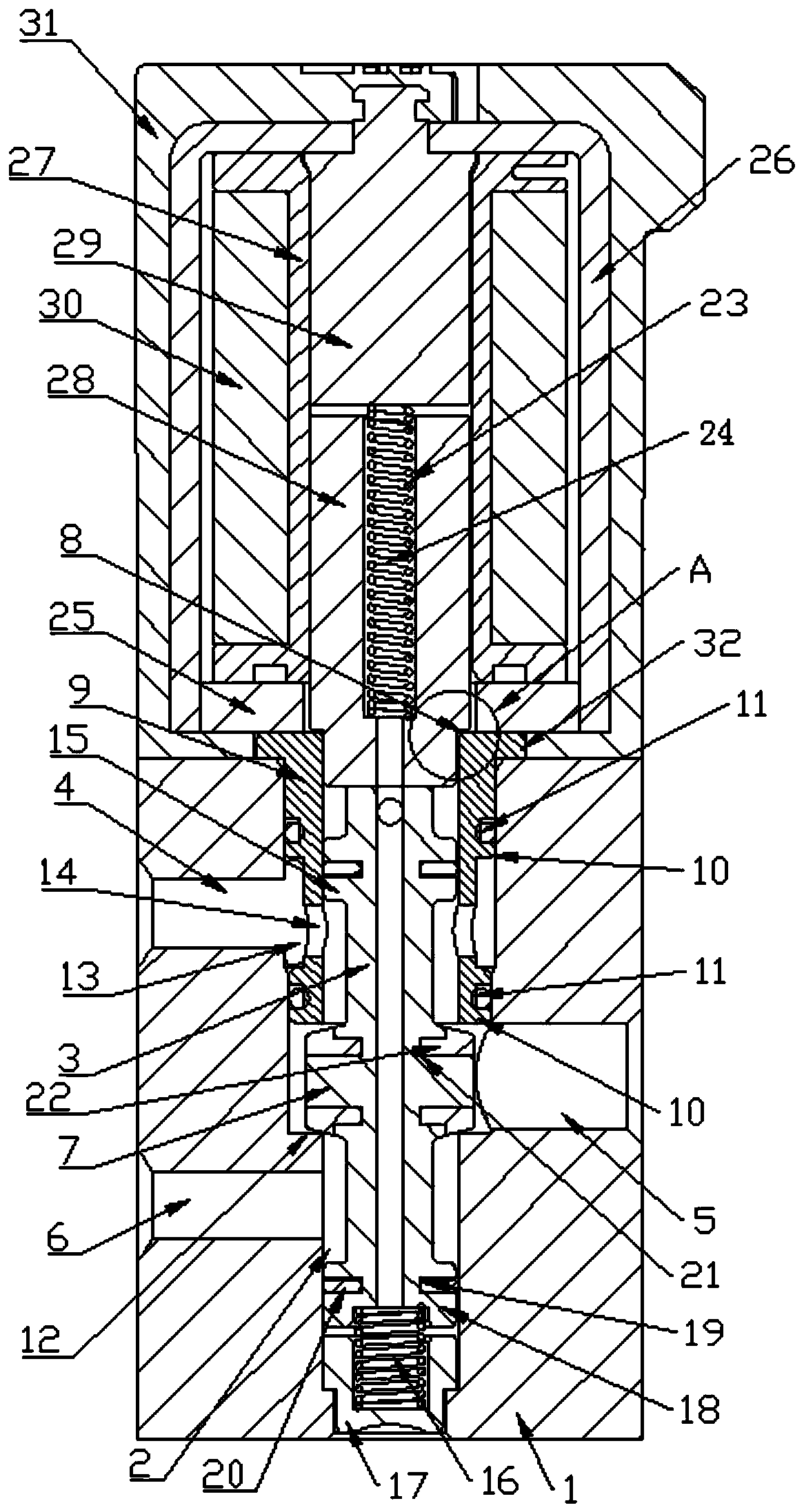

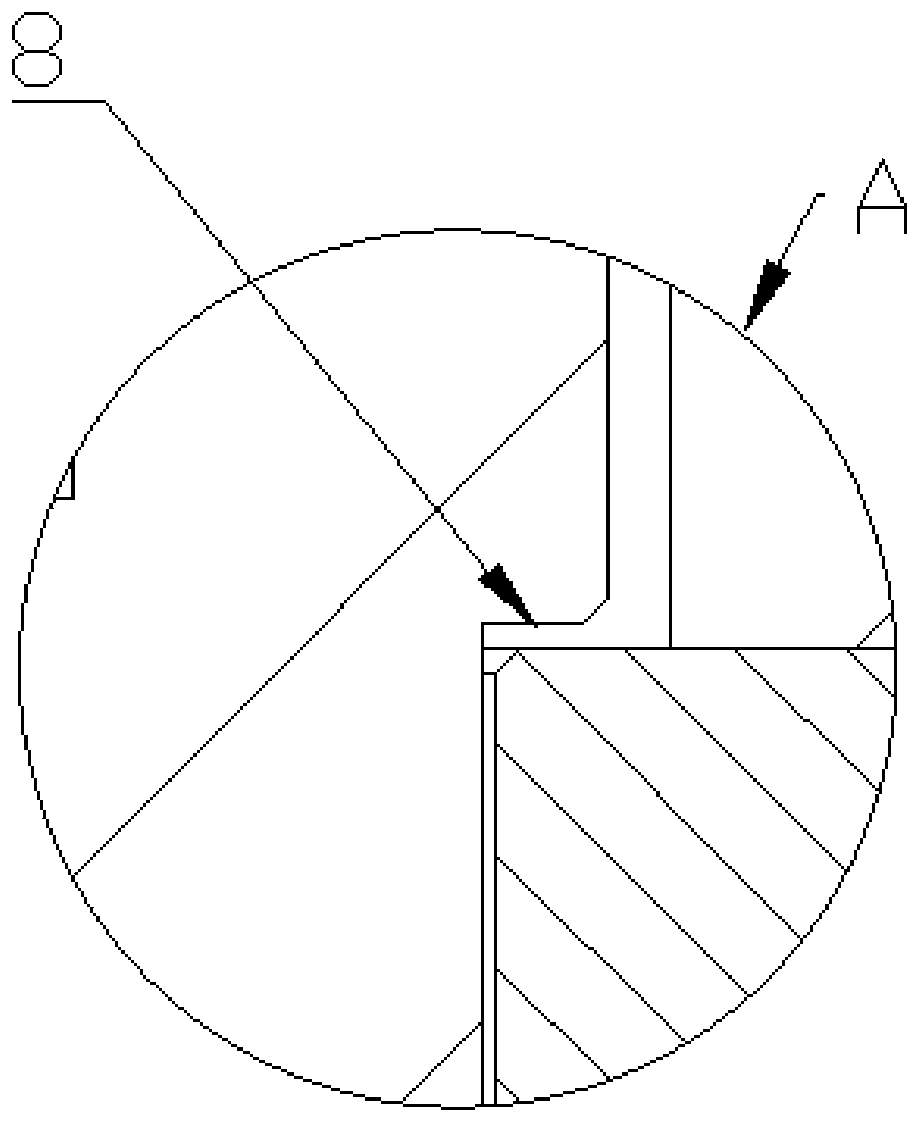

[0020] Embodiment 1: Referring to the accompanying drawings, the present invention adopts the following technical solution, a double-stroke separated direct-acting solenoid valve, including an electromagnetic control device and a valve body, characterized in that the valve body has a valve inner cavity, and the electromagnetic drive The device is installed at the opening end of the inner cavity of the valve; a valve stem is placed in the inner cavity of the valve, and the inner wall has a first channel, a second channel and a third channel; the valve stem is provided with a valve core, and the electromagnetic drive device controls the valve After the rod is displaced, the passage that connects the second passage with the third passage is blocked by the spool and disconnected, while the second passage communicates with the first passage, or the passage that connects the second passage with the first passage is blocked by the spool. Blocked and disconnected, the second channel co...

Embodiment 2

[0030] The difference between the present embodiment and the first embodiment is that the electromagnetic control device under the present embodiment includes: the second shell, the second magnetic plate embedded in the bottom of the second shell, and the second magnetic plate positioned in the inner cavity of the second shell. The two-shaped magnetic conductor, the I-shaped insulating cylinder two, the moving iron core two and the static iron core two, and the corresponding two side walls of the magnetic plate two are respectively in conflict with the inner surface of the bottom of the longitudinal part of the two-shaped magnetic conductor; The I-shaped insulating cylinder 2 is positioned in the inner cavity of the 冂-shaped magnetizer 2, the moving iron core 2 and the static iron core 2 located below the moving iron core 2 are positioned in the axial inner hole, and the radial outer peripheral side Coil 2 is wound, and the top of the moving iron core contacts with the top side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com