Sound wave toothbrush and its rotation axle electric machine

A shaft motor and toothbrush technology, applied in the field of pendulum shaft motors, can solve the problems of difficulty in reducing the vibration inertia of the vibrator, harsh hardness consistency and precision, and difficulty in improving the practical working frequency, etc., to achieve simple overall structure and manufacturing process, and reliable performance , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

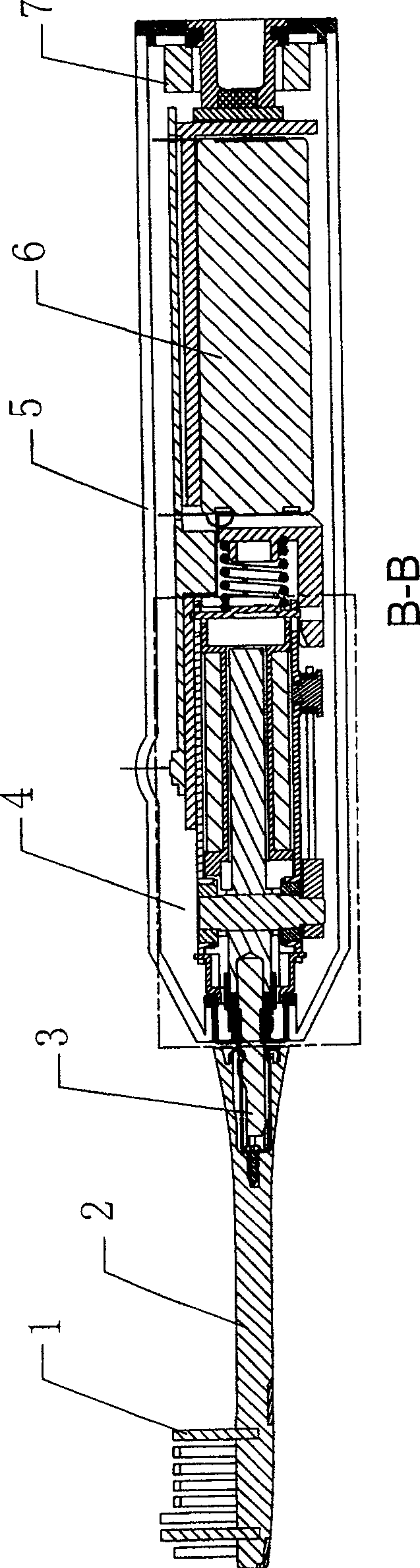

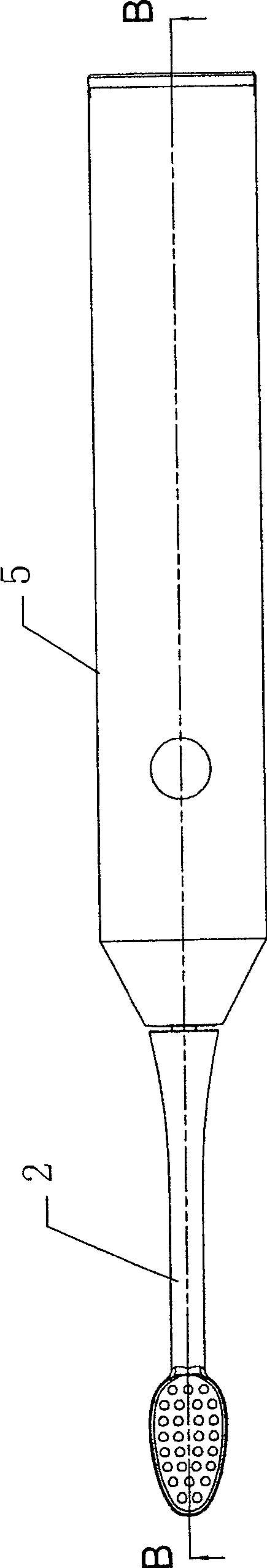

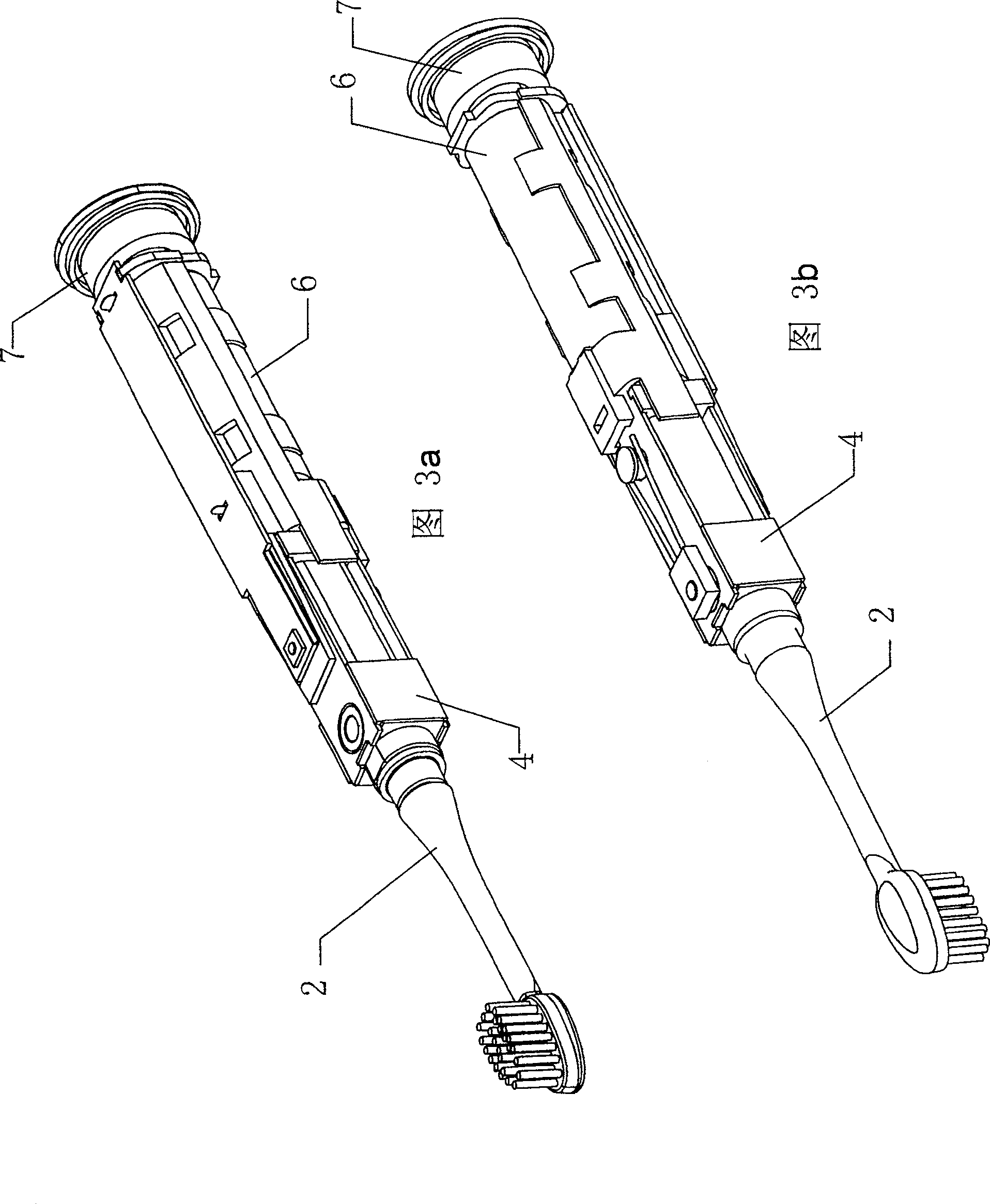

[0029] Further description will be made below in conjunction with the accompanying drawings.

[0030] Such as Figure 1-6 As shown, the sonic toothbrush includes a toothbrush head and a toothbrush body 5 double as a handle. The toothbrush head includes a brush rod 2 and a bristle 1 planted at one end of the brush rod 2. The toothbrush body 5 includes a housing and a pendulum motor arranged in the housing. 4 and the motor drive device 6, 7 among the figure is the secondary induction coil for charging, the pendulum motor 4 contains the electromagnetic coil 49 outside the bracket 51, the bracket 51 and the pendulum shaft 50 positioned in the bracket 51 inner cavity, fixed at the bracket 51 end Two magnets 47, 48, two magnets 47, 48 are arranged side by side and opposite in polarity, the rotating shaft 41 is fixed on the swing shaft 50, and the swing shaft 50 is installed on the two splints 46 and 46' of the bracket 51 through the rotating shaft 41, The power output end of the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com