a ship

A ship and hull technology, applied in ship propulsion, ship construction, ship parts, etc., can solve problems such as poor endurance and service life, loss of power source, complex structure, etc., to improve endurance and service life, improve The effect of low utilization rate and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

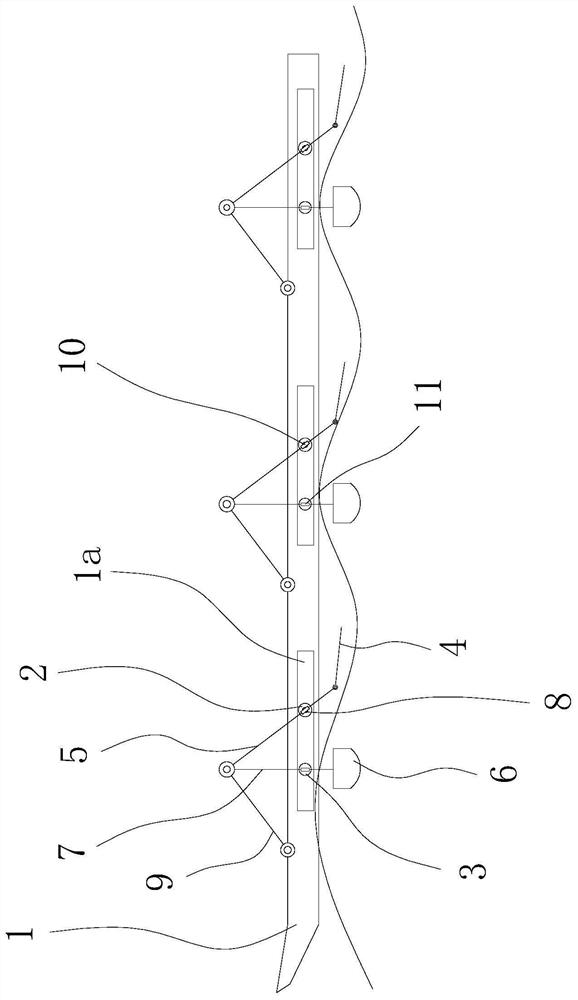

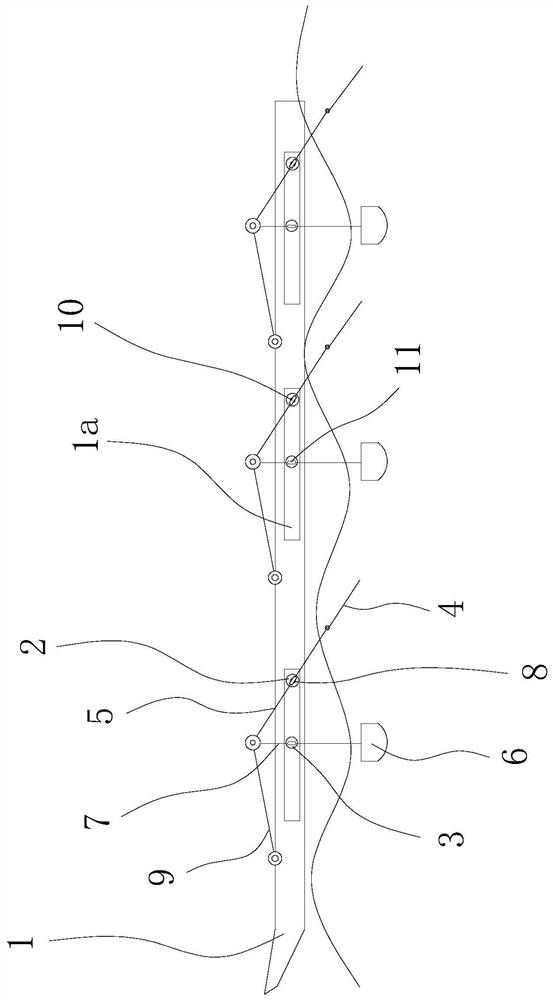

[0020] Such as figure 1 and 2 As shown, the ship includes a hull 1 and several groups of paddle assemblies arranged along the length direction of the hull 1. Both sides of the hull 1 are provided with several guide grooves 1a along the length direction of the hull 1, and the guide grooves 1a are along the length of the hull 1. direction, and each guide groove 1a is correspondingly connected with a group of the above-mentioned paddle assemblies.

[0021] The paddling assembly comprises a slide part one 2, a slide part two 3, a paddle plate 4, a connecting rod one 5, a connecting rod two 9, a lifting rod 7 and a buoyancy box 6. The first sliding piece 2 and the second sliding piece 3 are slidably connected in the corresponding guide groove 1a and can slide along the length direction of the hull 1. There is a gap between the first sliding piece 2 and the second sliding piece 3 and the groove wall of the guide groove 1a. Slider 1 2 is located behind slider 2 3, and guide sleeve ...

Embodiment 2

[0025]The structure of this embodiment is basically the same as that of Embodiment 1, the difference being that the paddle 4 and the connecting rod one 5 are hinged through the hinge shaft and between the paddle 4 and the connecting rod one 5, there is also a paddle 4 capable of limiting Limiting plate that swings forward about a hinge. The design of the limit plate makes the paddle board only rotate backwards, while the forward rotation is limited, so as to ensure that the paddle board 4 will not produce resistance to the forward movement of the ship, and can generate thrust on the water, thereby driving the ship forward move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com