Electronic ballast and operating method

An electronic ballast and circuit technology, applied in the direction of electric light sources, electrical components, lighting devices, etc., can solve problems that are not conducive to the protection of users' eyesight, and achieve the effects of constant luminous brightness, low heat generation, and high input impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

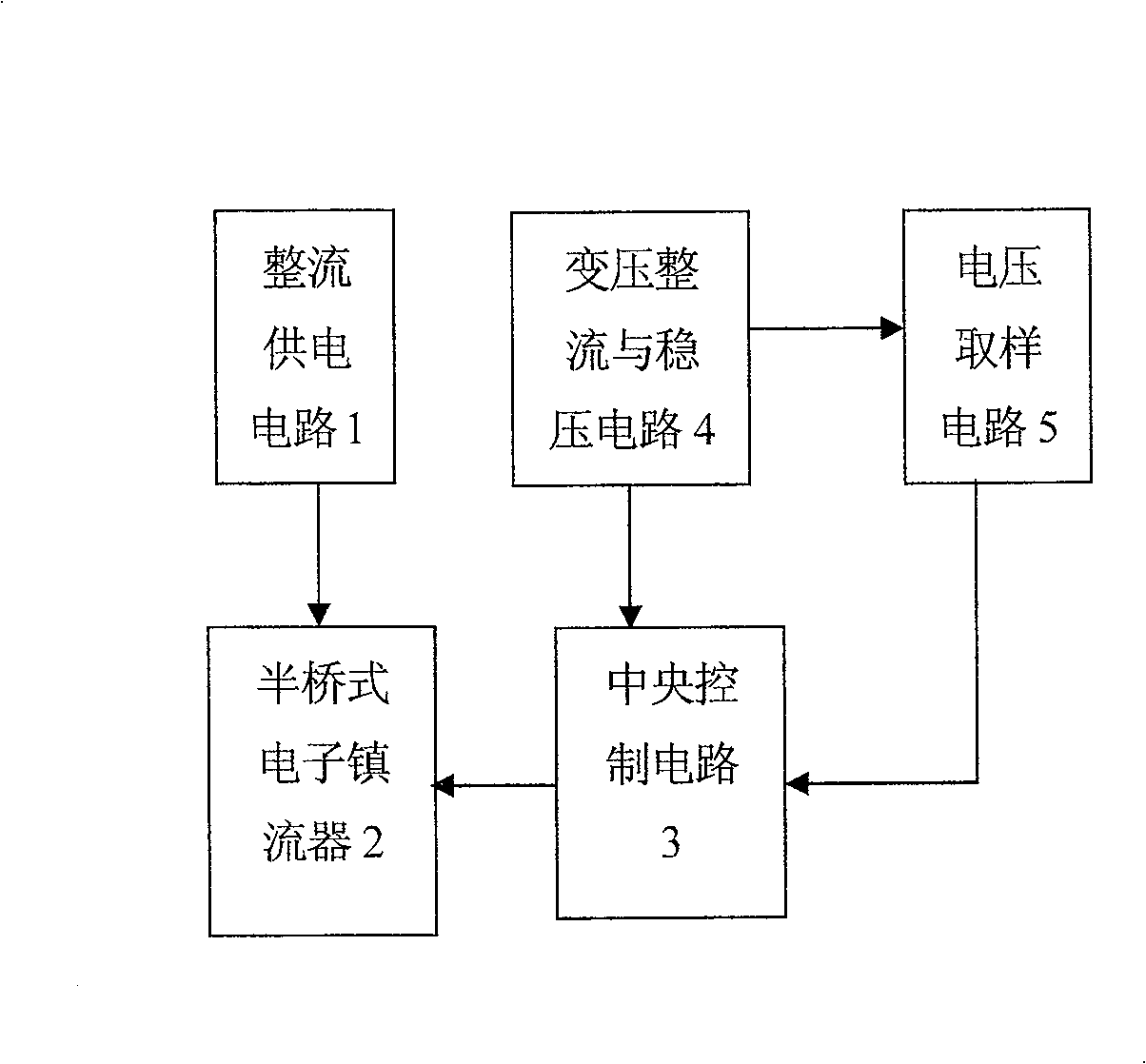

[0021] See figure 1 , The electronic ballast used in fluorescent lamps has a rectification power supply circuit 1, a half-bridge electronic ballast 2, a central control circuit 3, a transformer rectification and voltage stabilization circuit 4 and a voltage sampling circuit 5.

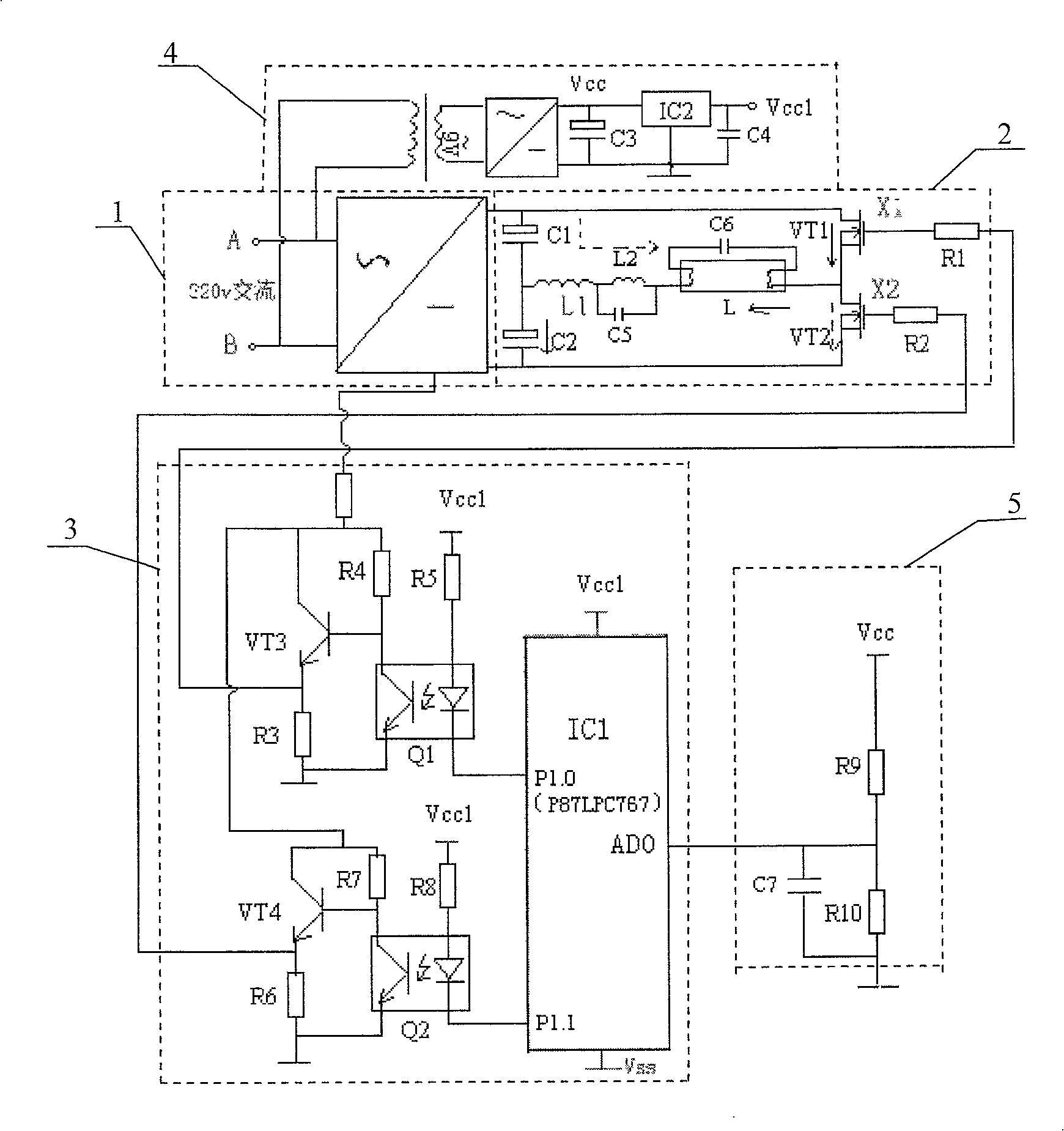

[0022] See figure 2 , In the rectification power supply circuit 1, the AC input terminals A and B of the ballast are connected to the 220V city AC.

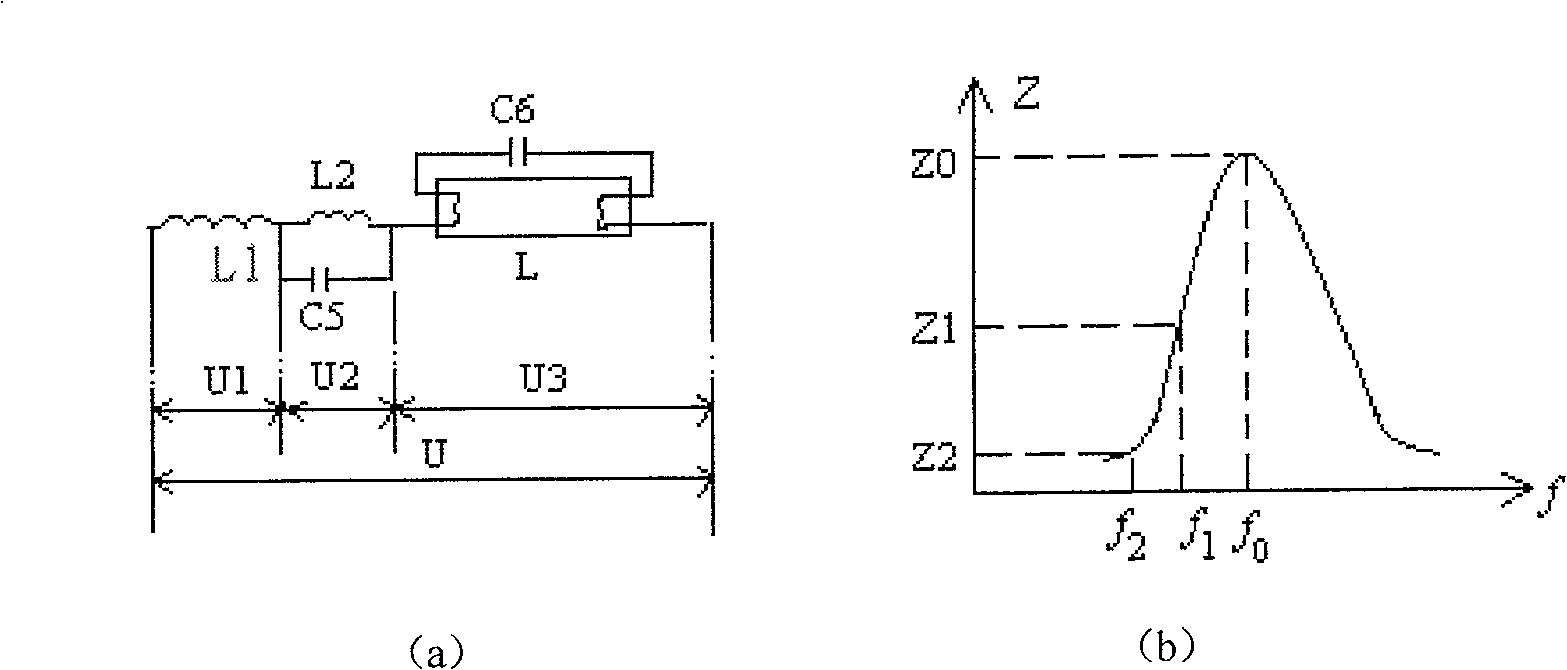

[0023] The series resonant circuit of the half-bridge electronic ballast 2 includes two VMOS field effect transistors VT1 and VT2, a starting circuit composed of a choke coil L1 and a filament preheating path capacitor C6, and a transformer composed of an inductance L2 and a capacitor C5 connected in parallel. Resistance circuit, filter capacitors C1 and C2.

[0024] Central control circuit 3 comprises central controller (model is the single-chip microcomputer IC1 of P87LPC767) and the driving circuit that links to each other with the control output en...

Embodiment 2

[0034] On the basis of Embodiment 1, this embodiment is modified as follows. The electronic ballast and its working method of this embodiment can be applied to HID lamps.

[0035] The working method of electronic ballasts applied to HID lamps, including:

[0036] ①. The P1.0 terminal and P1.1 terminal of the single-chip microcomputer IC1 output high and low levels alternately, and the two VMOS field effect transistors VT1 and VT2 in the half-bridge electronic ballast 2 are controlled by the driving circuit to be turned on and off alternately, Make the starting circuit generate series resonance and generate inverter frequency until the fluorescent tube or HID lamp is triggered to light up. ②, the resonant frequency of the rheostat circuit is always lower than the inverter frequency generated by the half-bridge electronic ballast 2; the central control circuit 3 detects the voltage fluctuation of the municipal AC through the voltage sampling circuit 5; when the measured municipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com