Combined adsorb refrigerating device

An adsorption refrigeration and composite technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low reliability of system operation, large loss of cooling capacity of condensation/evaporator, etc., and achieve easy batch production and compact structure. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

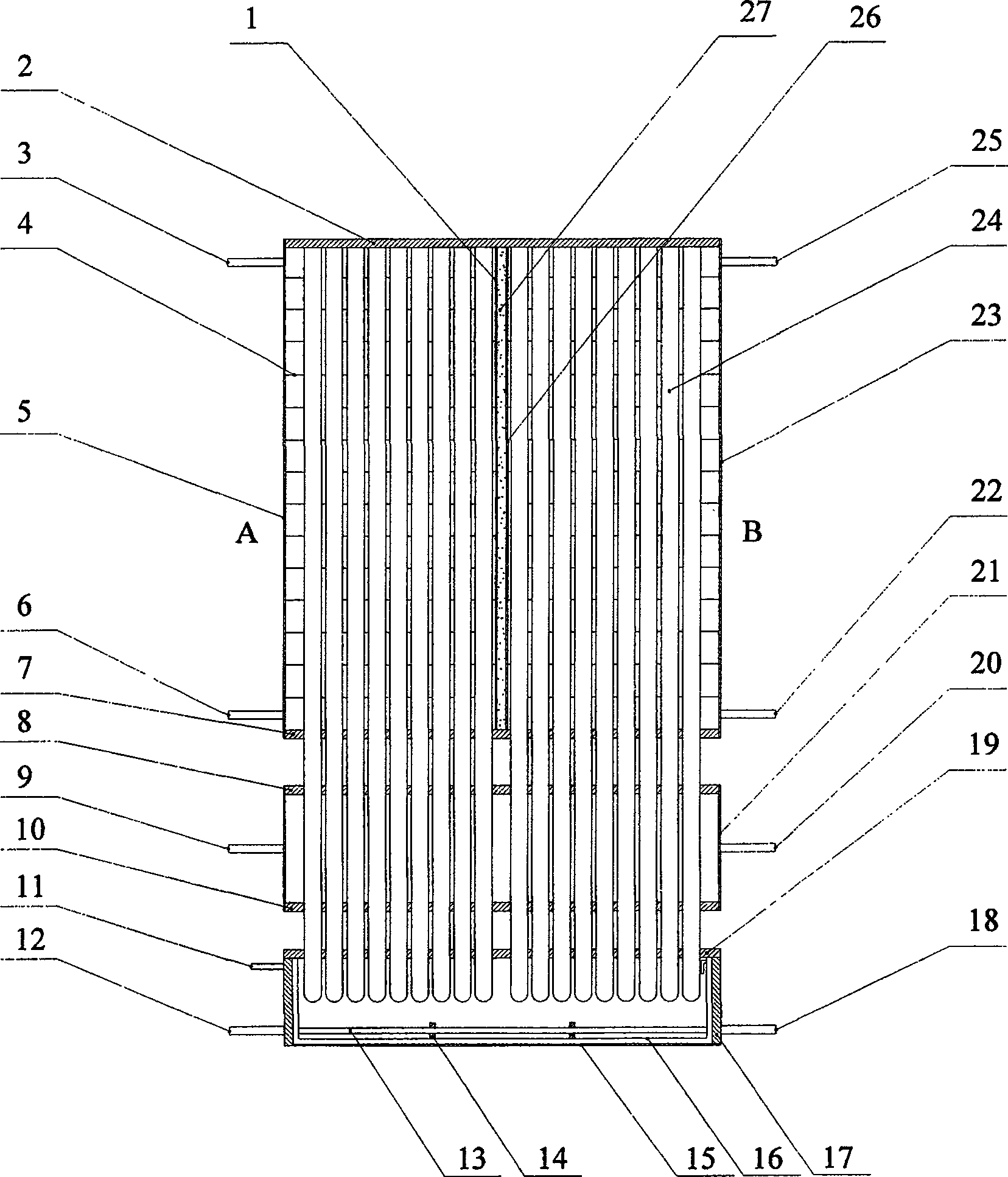

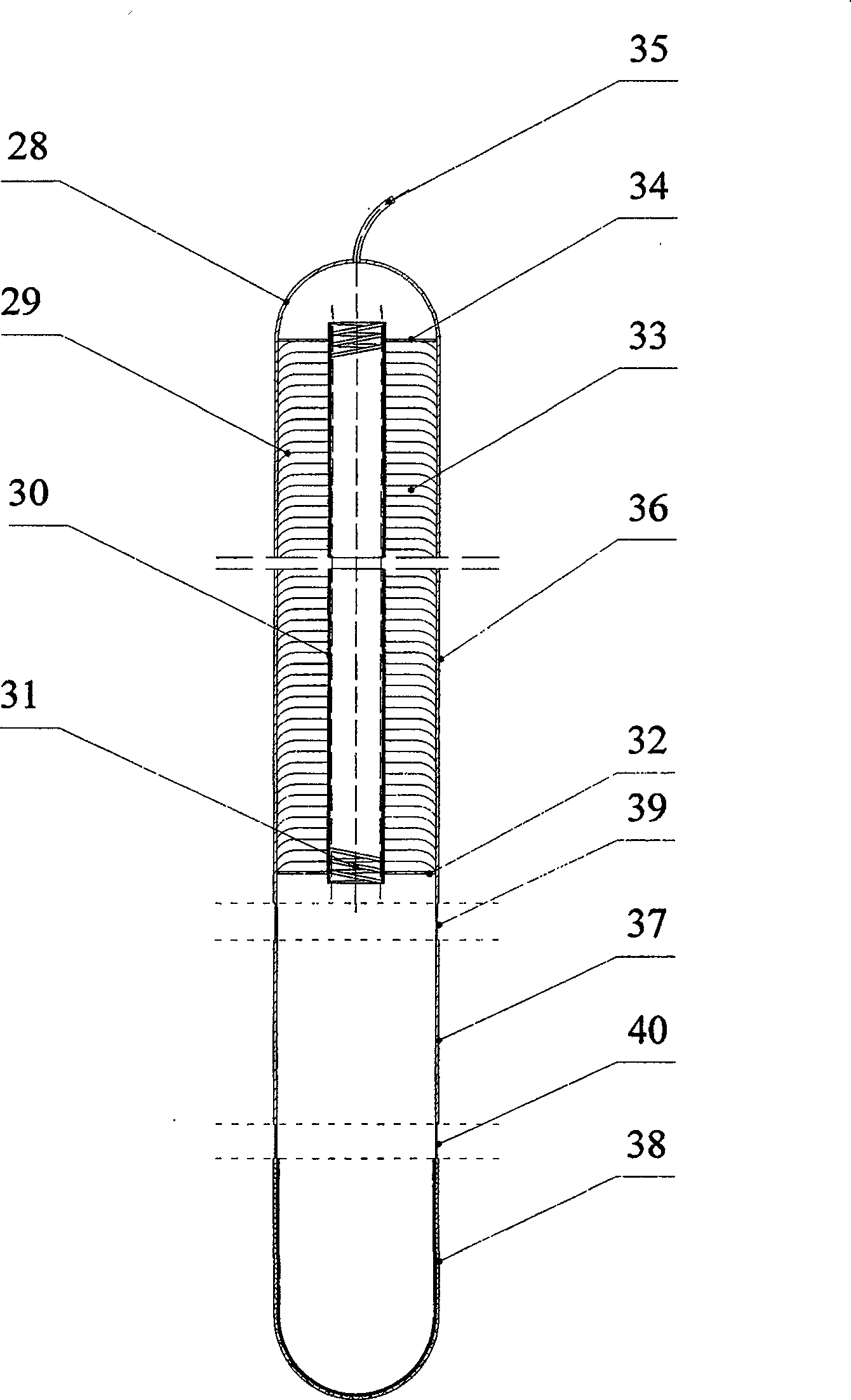

[0020] key reference figure 2 and combine figure 1 , a solid adsorption unit tube 24, which is divided into five parts: an adsorption generation section, a condensation section, an evaporation section and two heat insulation sections. A condensation section 37 is in the middle, and a thermal insulation section 39, 40 is provided between the adsorption generation section 36 and the condensation section 37 and between the condensation section and the evaporation section. The thermal insulation section 39, 40 can increase the heat transfer resistance by reducing the small wall thickness or increasing the length. The shell 28 is a circular metal tube. The adsorption generating section is surrounded by an upper sealing plate 34, a lower sealing plate 32, a casing 28 and a cylindrical metal mesh screen 30, and the adsorbent 33 is filled therein, and there are fins 29 in it to enhance heat transfer, and the fins 29 are circular, It is connected with the shell 28 by brazing proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com