Semiconductor device having a frontside contact and vertical trench isolation and method of fabricating same

A trench isolation and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as interfering with the performance of adjacent devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

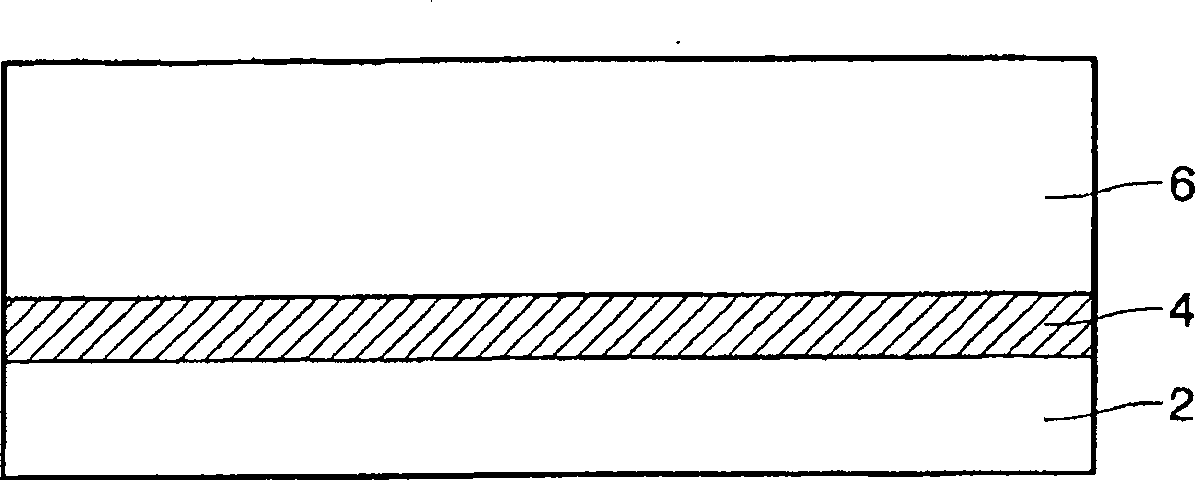

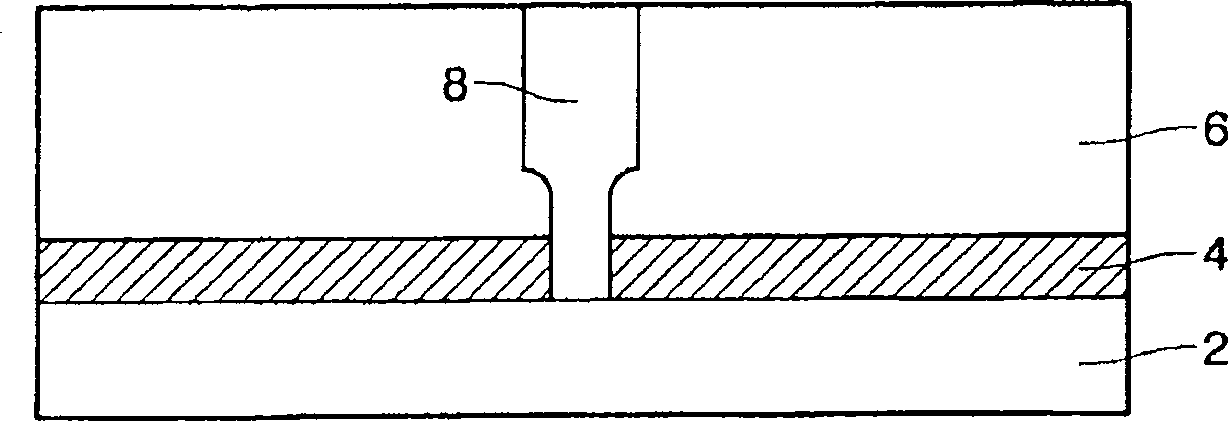

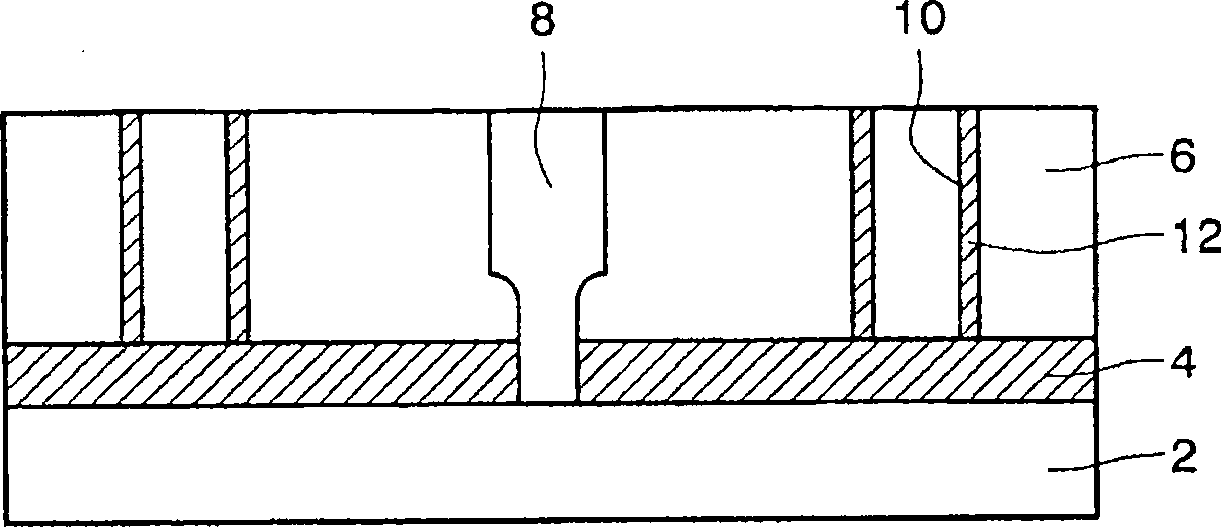

[0035] The following reference Figure 4 , Figures 4a-4f and Figure 5 , to describe in detail the fabrication method of the device according to the exemplary embodiment of the present invention.

[0036] step 100

[0037] consider as Figure 4 A silicon-on-insulator substrate 20 is shown, wherein the bottom substrate layer 2 is composed of silicon, and the insulating layer 4 is composed of silicon dioxide (SiO 2 ) composition, and the active semiconductor layer 6 is composed of silicon. In the first step, a field-induced oxide layer is grown on the exposed surface of the active semiconductor layer 6 of the substrate 20 by an oxidation process, the layer comprising silicon dioxide (SiO 2 ) layer 22, the oxidation process is well known to those of ordinary skill in the art. The purpose of the field oxide layer is to protect the active layer 6 of the substrate 20 and to form doped carriers. A subsequent nitridation step may also be performed to form a nitride (Si 3 N 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com