Semiconductor device having a frontside contact and vertical trench isolation and method of fabricating same

A semiconductor and trench technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as interfering with the performance of adjacent devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

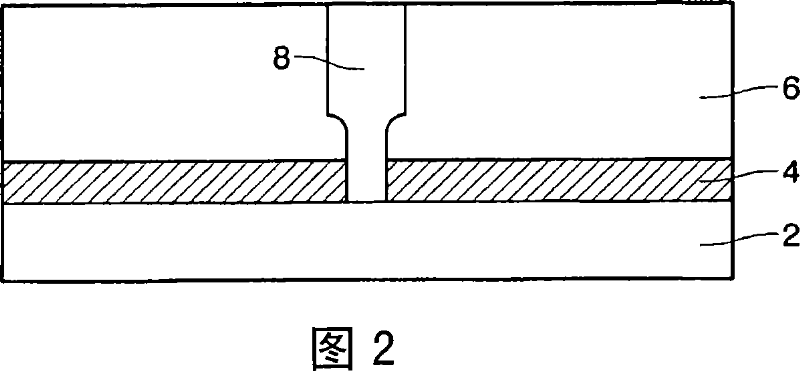

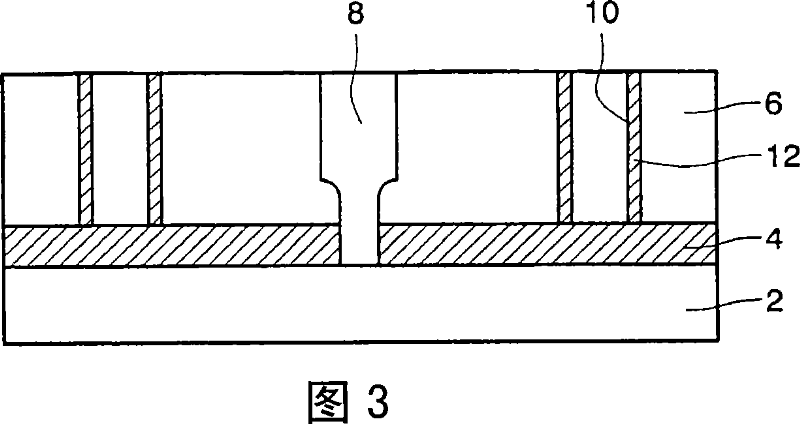

[0035] Referring to FIG. 4 , FIGS. 4 a - 4 f and FIG. 5 , the method for fabricating a device according to an exemplary embodiment of the present invention will be described in detail below.

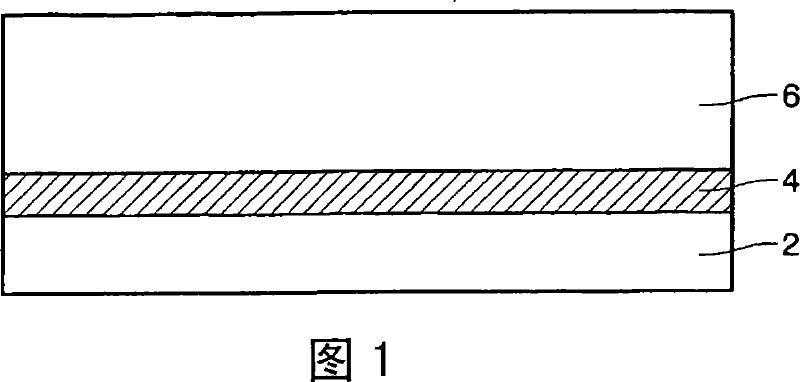

[0036] step 100

[0037] Consider a silicon-on-insulator substrate 20 as shown in FIG. 4, wherein the bottom substrate layer 2 is composed of silicon, and the insulating layer 4 is composed of silicon dioxide (SiO 2 ) composition, and the active semiconductor layer 6 is composed of silicon. In the first step, a field-induced oxide layer is grown on the exposed surface of the active semiconductor layer 6 of the substrate 20 by an oxidation process, the layer comprising silicon dioxide (SiO 2) layer 22, the oxidation process is well known to those of ordinary skill in the art. The purpose of the field oxide layer is to protect the active layer 6 of the substrate 20 and to form doped carriers. A subsequent nitridation step may also be performed to form a nitride (Si 3 N 4 ) layer 24. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com