Upper and lower prefastening parallel connection structure six-dimensional force sensor

A six-dimensional force sensor and preloading technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve the problems of large stress coupling and inter-dimensional coupling, poor zero-crossing of force on the force measuring platform, and complex calibration methods. Achieve the effects of reduced stress coupling, increased stiffness, and simplified calibration algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

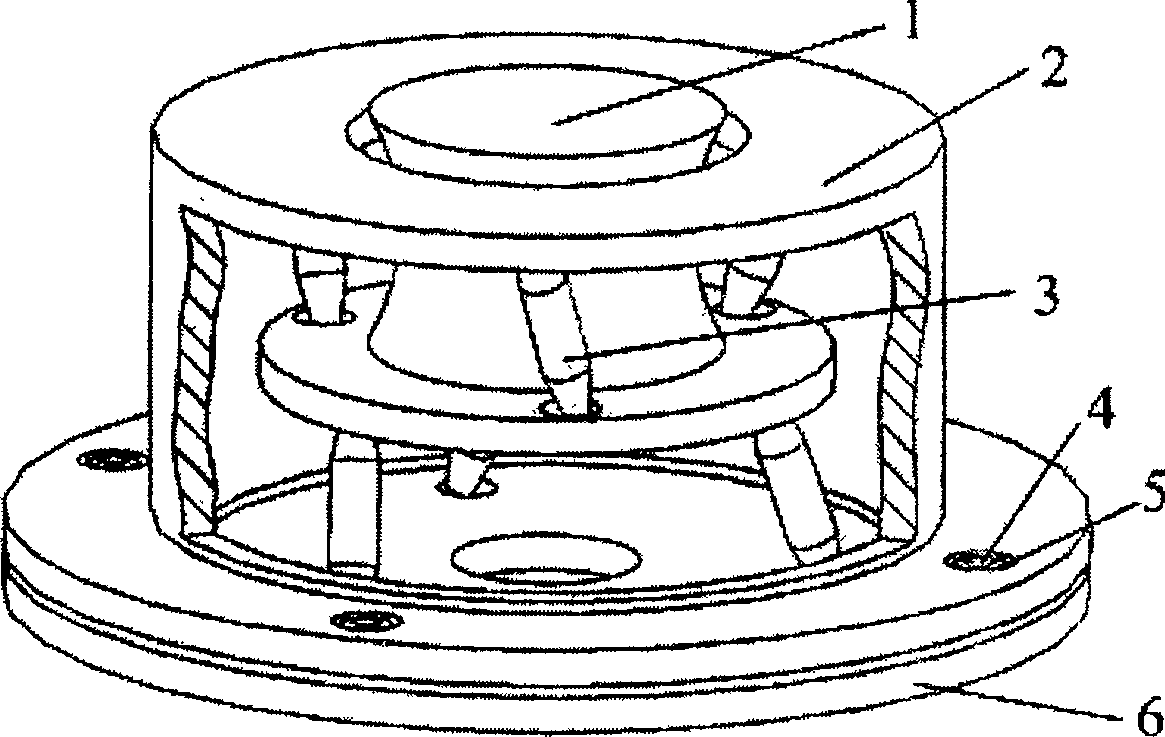

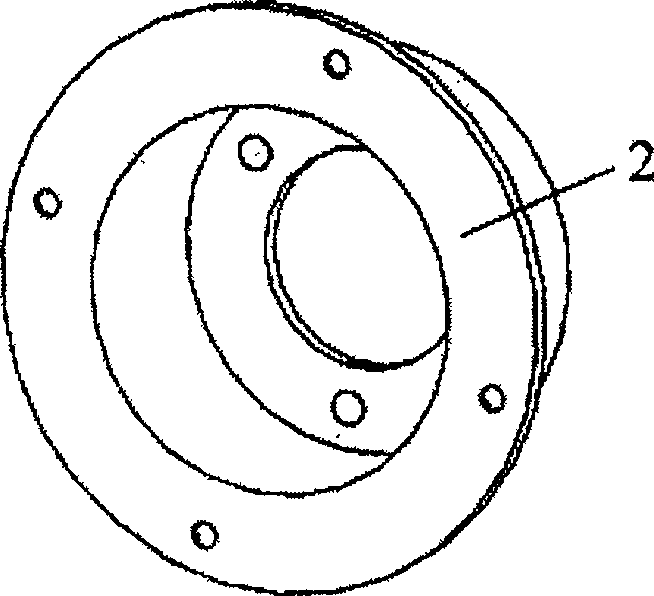

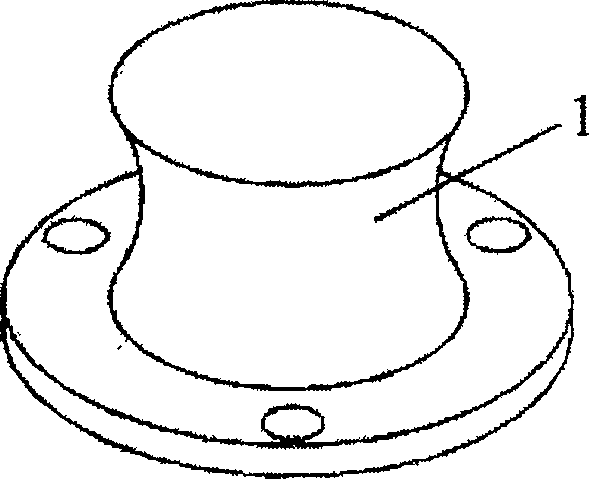

[0013] The upper and lower pre-tightening parallel structure six-dimensional force sensor consists of a pre-tightening platform 2, a force-measuring platform 1, a base 6, six detection components 3, and pre-tightening bolts 4 and nuts 5 (see figure 1 ), the force-measuring platform 1 is fixedly connected by a chassis with coincident axes and a load-bearing disc, three ball sockets are distributed on the upper and lower sides of the chassis edge of the force-measuring platform 1, and the three ball sockets are evenly distributed on the same circumference; The tight platform 2 is a shell member, and there is a round hole on the top of the shell. The load-bearing disk of the force measuring platform 1 protrudes from the round hole. There are three ball sockets distributed on the inner ring surface of the top of the shell, and the three ball sockets are evenly distributed. On the same circumference, evenly distributed bolt holes are opened on the connecting flange at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com