Screw-type waveform jacket condensator

A spiral and condenser technology, which is applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of fruit juice losing its original taste, unfavorable market competition, and inability to guarantee product quality. Reasonable design and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

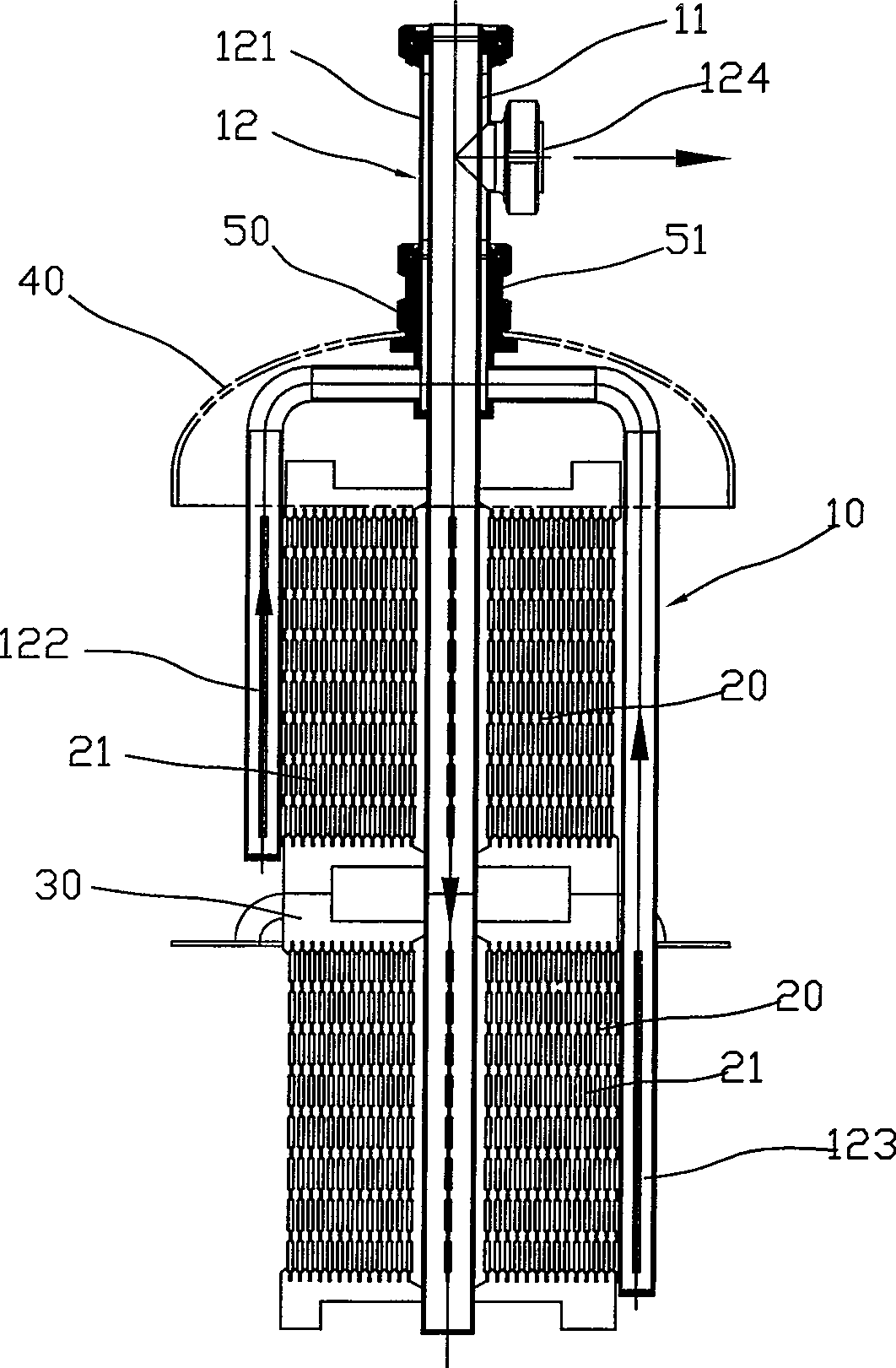

[0021] Such as figure 1 As shown, a spiral corrugated jacket condenser includes a refrigerant inlet and outlet bracket (10) and two sets of spiral corrugated jackets (20), wherein:

[0022] The refrigerant inlet and outlet bracket (10) is composed of a refrigerant inlet pipe (11) and a refrigerant outlet pipe (12). The refrigerant outlet pipe (12) includes a base pipe (121) and extends along both sides of the base pipe (121) and communicates with it. The upper and lower refrigerant outlet pipes (122, 123); the base pipe (121) covers the upper end of the refrigerant inlet pipe (11), and a refrigerant outlet (124) is arranged on the base pipe (121).

[0023] Two sets of spiral corrugated jackets (20), which are arranged vertically up and down, and are located between the upper and lower refrigerant outlet pipes (122, 123), and the refrigerant inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com