A compound addictive for lowering CO content in cigarette smoke and application thereof

A compound additive and carbon monoxide technology, which is applied in the fields of application, tobacco, and tobacco treatment, can solve the problems of rising manufacturing and use costs, human hazards, etc., and achieve the effects of convenient production, low cost, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Dissolve 0.5kg of sodium carbonate, 0.3kg of sodium lactate and 0.2kg of sodium acetate in 1.940kg of distilled water, heat and stir at a temperature range of 40-60°C, add 60g of flue-cured tobacco extract, stir and dissolve. Then add 1 kg of freshly prepared organic acid solution of copper hydroxide, and mix evenly to obtain composite additive A.

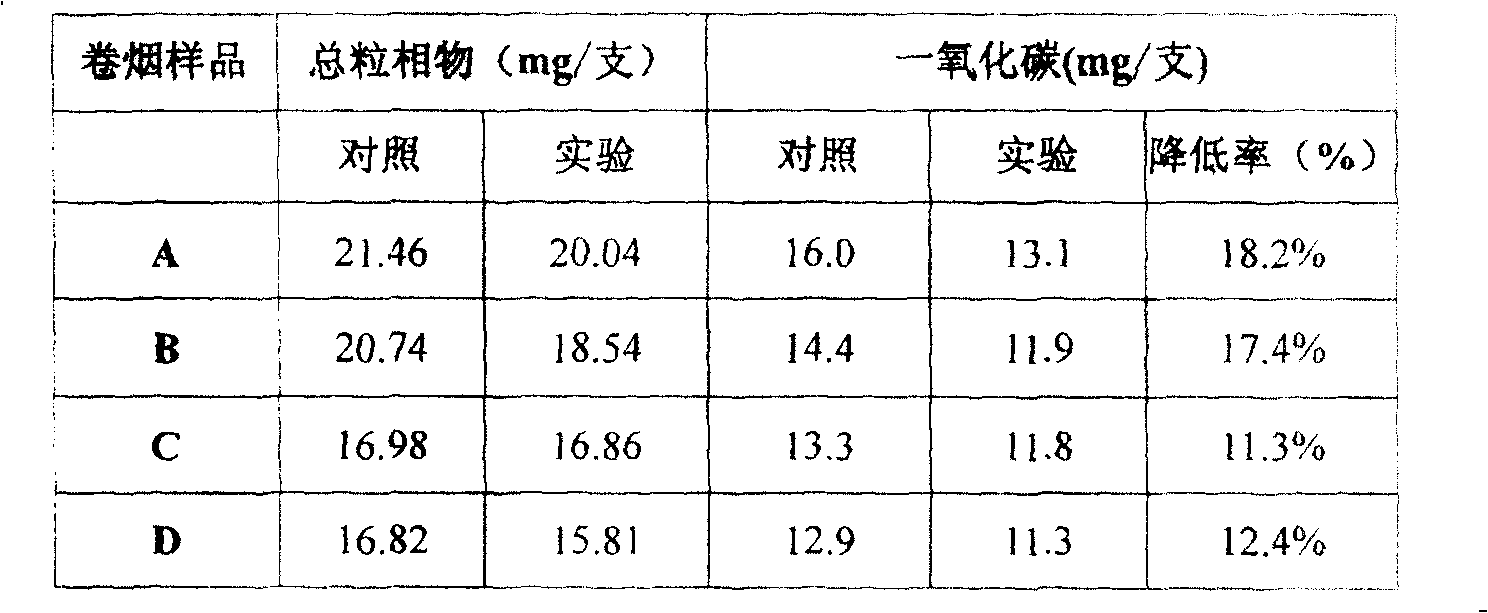

[0043] Take 2kg of compound additive A prepared and spray evenly on 100kg of tobacco leaves with a high-pressure nozzle. The spraying process is carried out during the super-return feeding process of the leaf group, and then according to the conventional cigarette process, it is shredded, flavored, and wrapped. The craft rolls into cigarettes. On the same production line, the control cigarettes were rolled according to the same cigarette technology. Cigarette mainstream smoke analysis and cigarette sensory quality evaluation were carried out according to standard methods. The results showed that the amount of carbon monoxi...

Embodiment 2

[0045] Dissolve 0.2kg of sodium carbonate, 0.1kg of sodium lactate and 0.2kg of sodium acetate in 1.940kg of distilled water, heat and stir at a temperature range of 40-60°C, add 60g of flue-cured tobacco extract, stir and dissolve. Then add 1.0 kg of freshly prepared organic acid solution of copper hydroxide, and mix evenly to obtain composite additive B.

[0046] Take 1.5 kg of the prepared composite additive B solution, and carry out the addition experiment in the same way as in Example 1. The results showed that the amount of carbon monoxide in cigarette smoke was reduced from 16.2mg / cigarette to 14.0mg / cigarette, and the reduction rate was 13.6%. The original style of the cigarette remains unchanged, and the quality of smoking is improved to a certain extent.

Embodiment 3

[0048] Dissolve 0.5kg of sodium carbonate, 0.5kg of sodium lactate and 0.5kg of sodium acetate in 2.940kg of distilled water, heat and stir at a temperature range of 40-60°C, add 60g of flue-cured tobacco extract, stir and dissolve. Then add 1 kg of freshly prepared organic acid solution of copper hydroxide, and mix evenly to obtain composite additive C.

[0049] Take 2 kg of the prepared composite additive C solution, and carry out the addition experiment in the same way as in Example 1. The results showed that the amount of carbon monoxide in cigarette smoke was reduced from 16.2mg / stick to 13.2mg / stick, and the reduction rate was 18.5%. Moreover, the original style of the cigarette can be kept unchanged, and it has a certain effect on enriching the aroma of the cigarette, softening the smoke, and reducing stimulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com