Additive for reducing cigarette smoke carbon monoxide (CO) and preparation method and application thereof

A technology of cigarette smoke and additives, applied in the fields of application, chemical instruments and methods, tobacco, etc., can solve the problems of high cost of carbon monoxide technology, affecting the quality of smoking, etc., achieve significant industrial application value and social benefits, and improve safety and comfort The effect of improving the quality of sex and inhalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

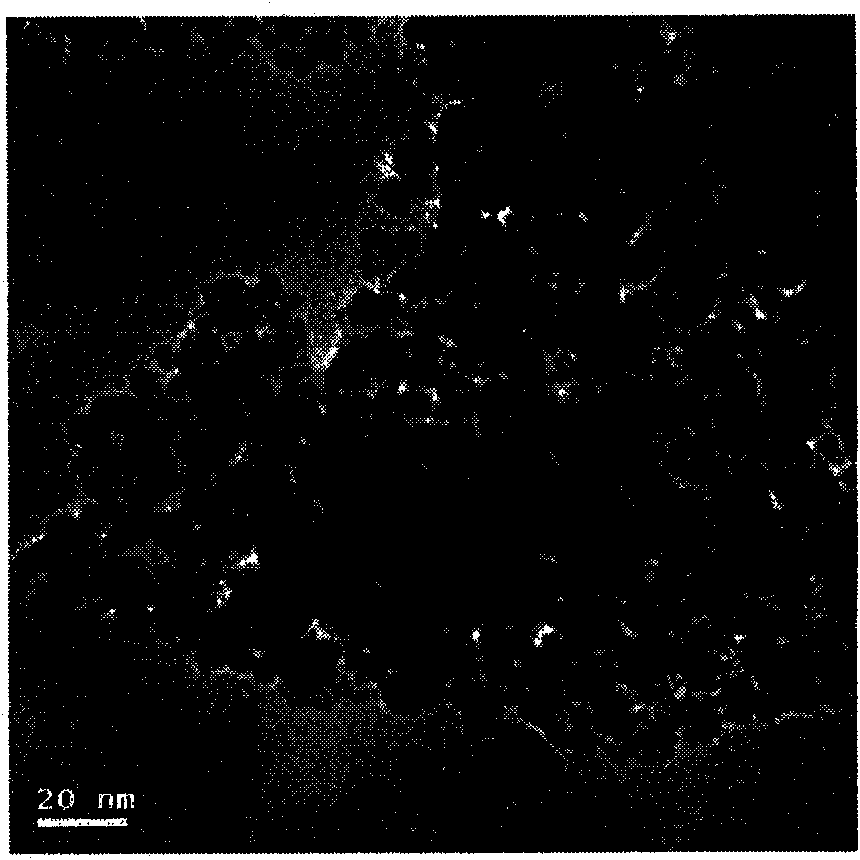

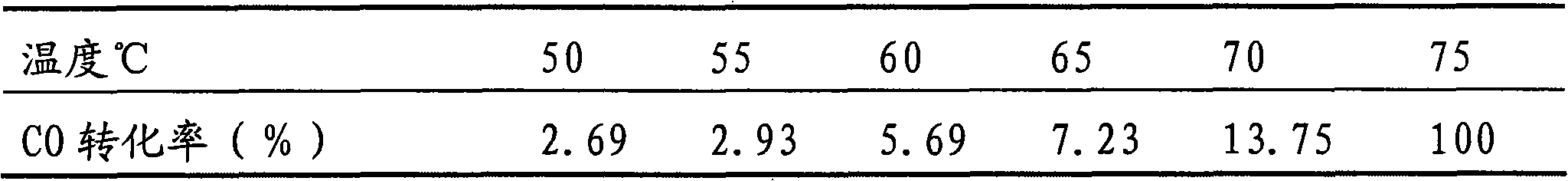

[0034] Take 0.25 g Ni(NO 3 ) 2 ·6H 2 O, 0.5 g Co(NO 3 ) 2 ·6H 2 O, 50 g Cu(NO 3 ) 2 ·3H 2 O, 0.5 g C 16 h 36 o 4 Ti, 0.1 g YCl 3 ·6H 2 O, 4.6 g ZrClO 2 ·8H 2 O, 5.0 g Mn(NO 3 ) 2 ·6H 2 O and 60 g CeCl 3 ·7H 2 Dissolve O in deionized water, heat up to 30°C after complete dissolution, adjust the pH value to 9 with ammonia water, and after the reaction is stable, add 4A molecular sieve carrier that is 1 times the weight of the active component that has been dissolved in deionized water, and continue stirring. Stand still, filter, wash with deionized water and alcohol, age and dry at 120°C for 12 hours, then bake at 500°C for 10 hours, cool to room temperature and pulverize to 360 mesh. The above additives are analyzed by transmission electron microscopy, and the active catalytic components and additives are dispersed on the carrier in nanometer size, and the particle size is between 5-10nm, see figure 1 .

[0035] Take 200mg of additives and put them into the...

Embodiment 2

[0044] Take 0.25 g Ni(NO 3 ) 2 ·6H 2 O, 0.5 g Fe(NO 3 ) 3 9H 2 O, 50 g Cu(NO 3 ) 2 ·3H 2 O, 0.5 g C 16 h 36 o 4 Ti, 0.1 g YCl 3 ·6H 2 O, 4.6 g ZrClO 2 ·8H 2 O, 5.0 g Mn(NO 3 ) 2 ·6H 2 O and 50 g CeCl 3 ·7H 2 O was dissolved in deionized water. After the dissolution was complete, the temperature was raised to 40°C, and the pH value was adjusted to 11 with KOH. After the reaction was stable, the insoluble matter in the solution was filtered out, washed with deionized water and alcohol, and aged and dried at 120°C. After 10 hours, it was calcined at 450° C. for 6 hours, cooled to room temperature, and pulverized to 400 mesh.

[0045] Dissolve and dilute the above-mentioned additives with ethanol, add 58.5 g of diluent (11.7 g of the additive) to 1170 g of shredded tobacco, and evenly add it to the shredded tobacco after dilution, place it at room temperature for 12 hours for absorption, and make cigarettes according to the conventional process.

[0046] Carbon...

Embodiment 3

[0050] Take 0.25g Ni(NO 3 ) 2 ·6H 2 O, 0.5 g Co(NO 3 ) 2 ·6H 2 O, 50 g Cu(NO 3 ) 2 ·3H 2 O, 0.8 g Zn(NO 3 ) 2 ·6H 2 O, 0.4 g C 16 h 36 o 4 Ti, 0.1 g YCl 3 ·6H 2 O, 4.6 g ZrClO 2 ·8H 2 O, 4.0 g Mn(NO 3 ) 2 ·6H 2 O and 65 g CeCl 3 ·7H 2 O was dissolved in deionized water. After the dissolution was complete, the temperature was raised to 30°C, and the pH value was adjusted to 9 with ammonia water. After the reaction was stable, a porous alumina carrier that was 0.5 times the weight of the active component that had been dissolved in deionized water was added, and continued Stir, stand still, filter, wash with deionized water and alcohol, age and dry at 90°C for 10 hours, then roast at 650°C for 4 hours, cool to room temperature and pulverize to 300 mesh.

[0051] Dissolve and dilute the above-mentioned additives with ethanol, add 29.2 g of diluent (5.85 g of the additive) to 1170 g of shredded tobacco, and evenly add it to the shredded tobacco after dilution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com