Welding joint for fuel tank

一种熔接接头、燃料箱的技术,应用在树脂熔接接头领域,能够解决熔接强度降低、防燃料渗透性和熔接强度劣化、熔接部防燃料渗透性劣化等问题,达到熔接强度保持、优良防水性、提高计算可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

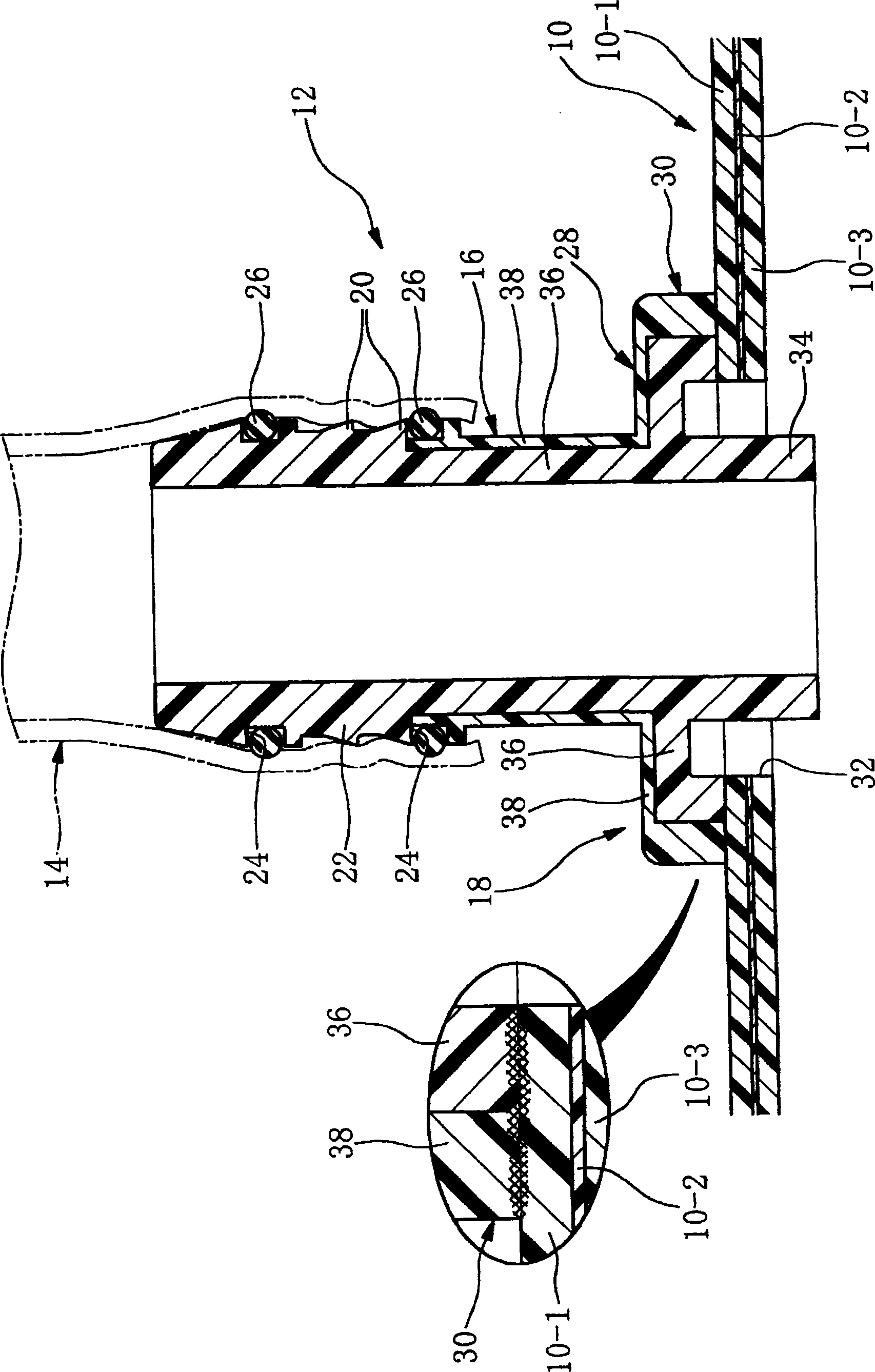

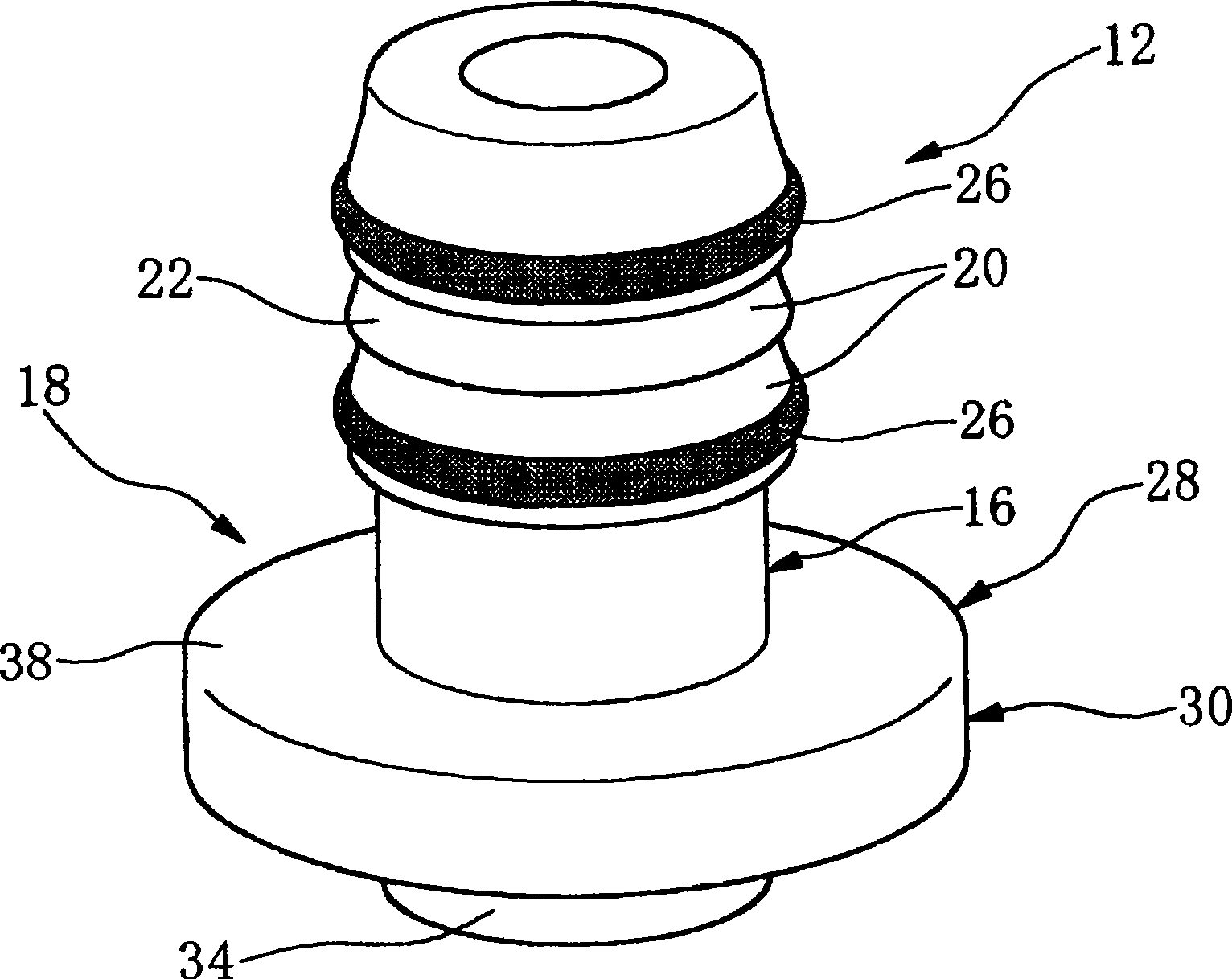

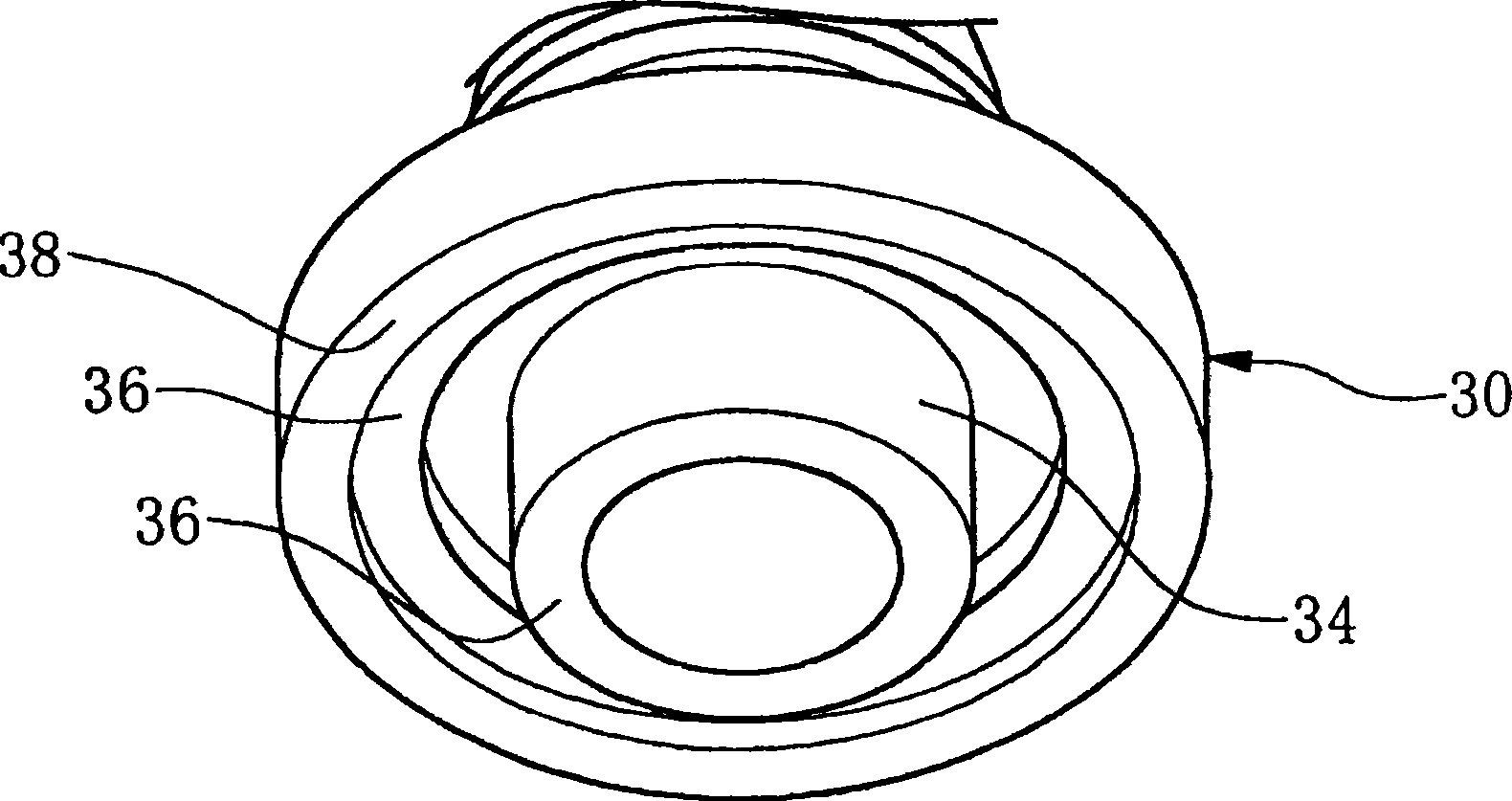

[0075] exist figure 1 In , reference numeral 10 denotes a resin fuel tank. In this embodiment, a resin fuel tank 10 has an outer layer member 10-1 and an inner layer member 10-3 made of HDEP resin. Further, the fuel tank 10 has a cross-sectional structure in which a thin barrier member 10-2 is sandwiched by an outer layer member 10-1 and an inner layer member 10-3.

[0076] Incidentally, the barrier member 10-2 also constitutes an inner layer with respect to the outer layer 10-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com