Simulation method of offshore boundary conditions for flng unit liquefaction process

A technology of boundary conditions and simulation methods, applied in the field of offshore petroleum engineering, can solve the problems of large process design margin, high economic cost, and time-consuming, and achieve the effect of improving calculation reliability, shortening calculation time, and solving practical problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

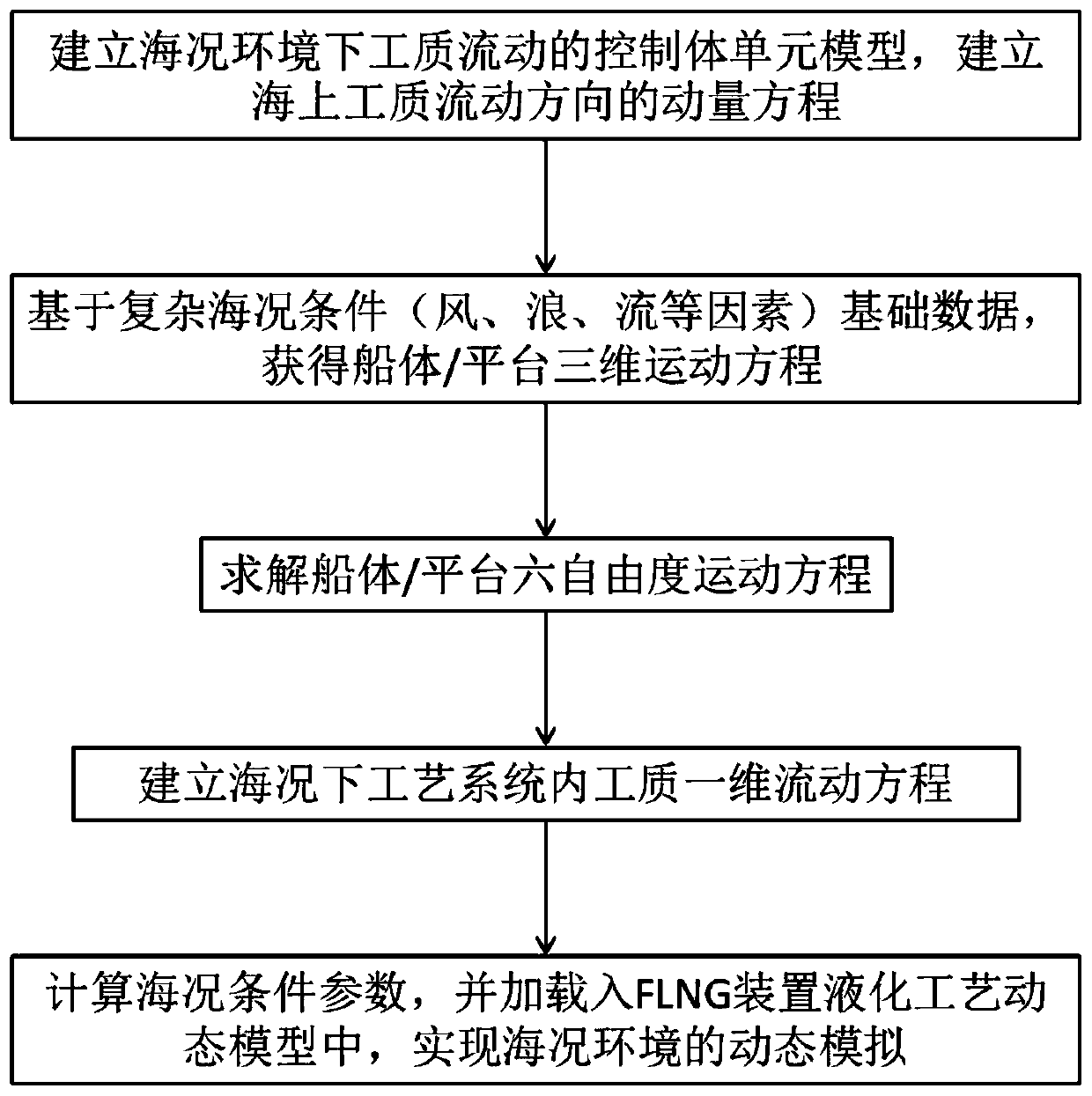

[0035] Such as figure 1 As shown, a kind of offshore boundary condition simulation method for FLNG unit liquefaction process provided by the present invention comprises the following steps:

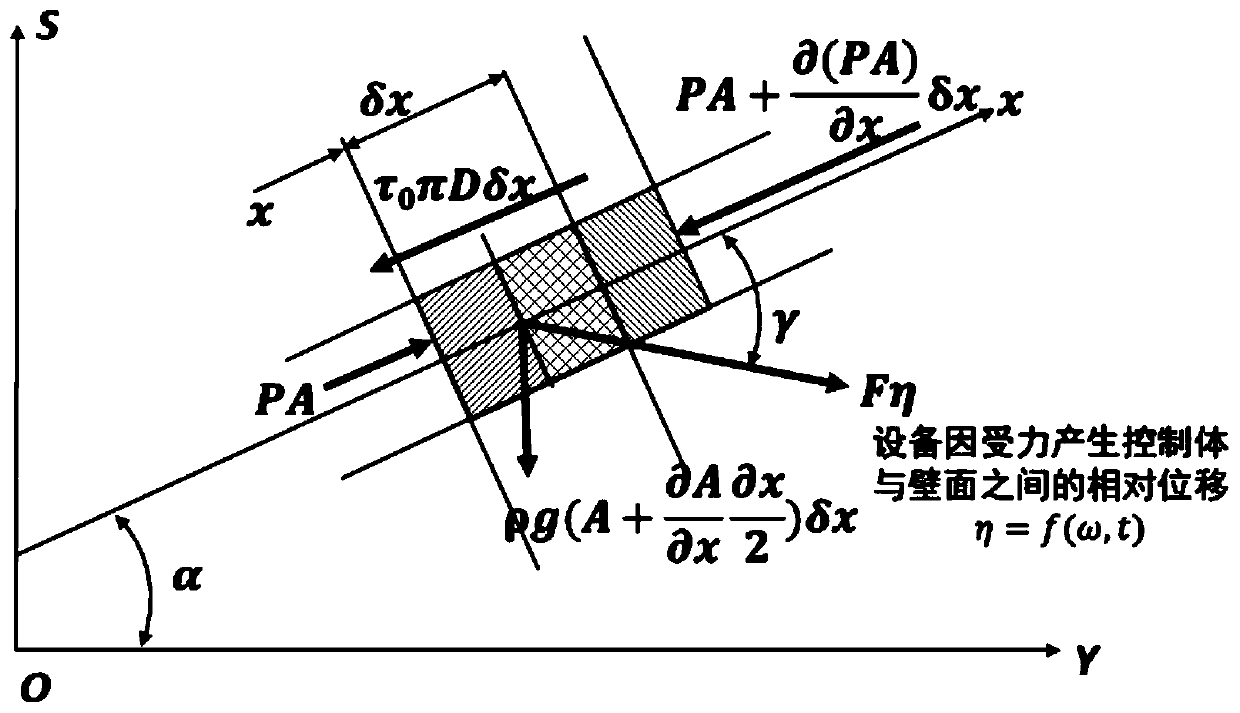

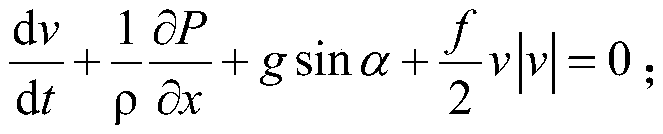

[0036] (1) Establish a three-dimensional control volume unit model for the flow of working fluid in the FLNG liquefaction process system under sea conditions, analyze the action mode of sea conditions in the process of working medium flow, and obtain the flow of working medium under the conditions of sea conditions and hull or platform motion The momentum equation for the direction;

[0037] (2) Based on the basic data of complex sea conditions in the actual operating sea area (such as wind, wave, current and other factors), obtain the three-dimensional motion of the hull or platform, and obtain the three-dimensional motion equation of the hull or platform;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com