Aerial craft oil mass measurement error correcting method

A measurement error, aircraft technology, applied in the aviation field, can solve the problems of measurement result jump, engine working state test, measurement result error, etc., achieve the effect of accurate measurement of remaining fuel, avoid accidental measurement error, and eliminate cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

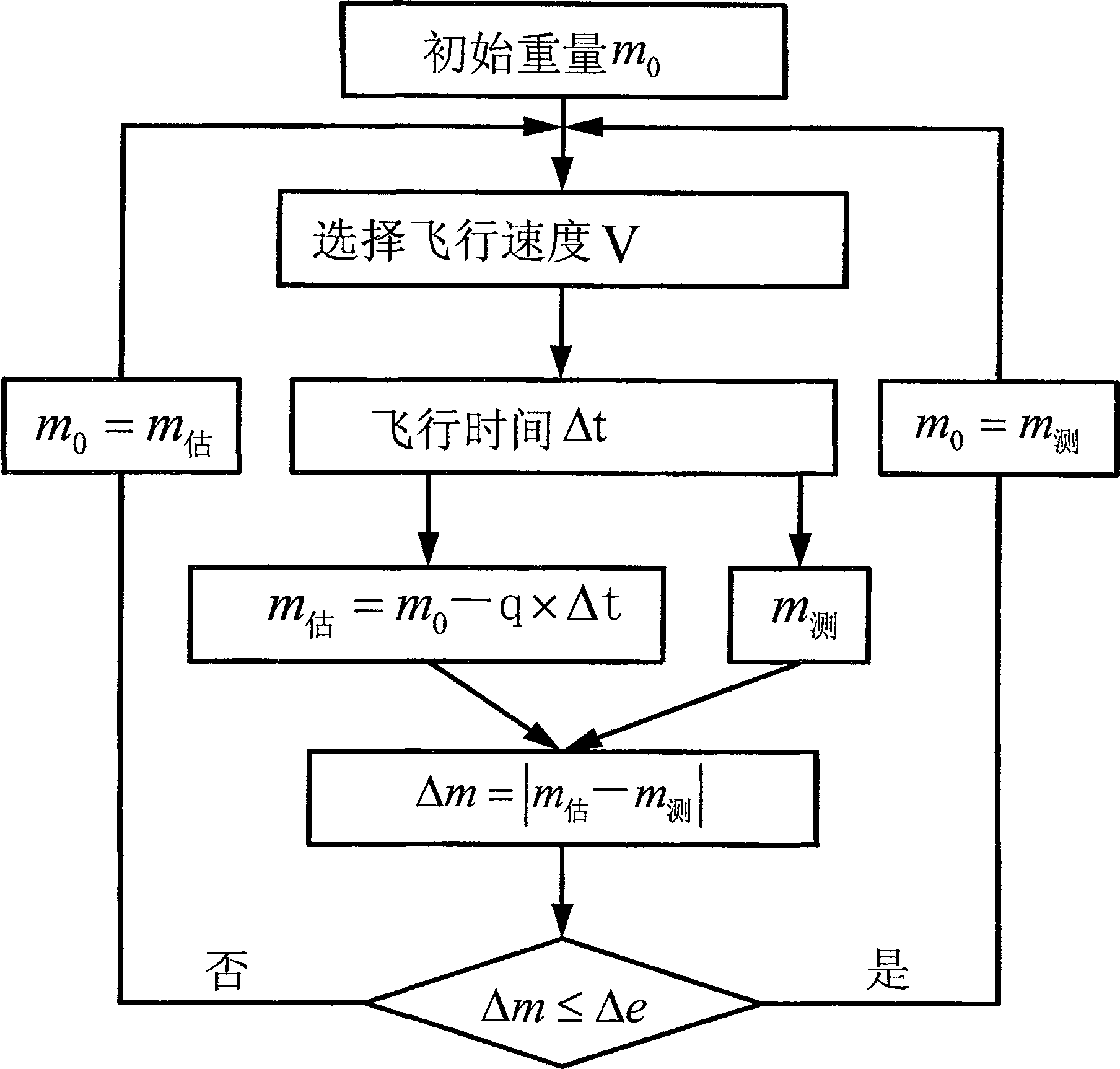

Method used

Image

Examples

Embodiment

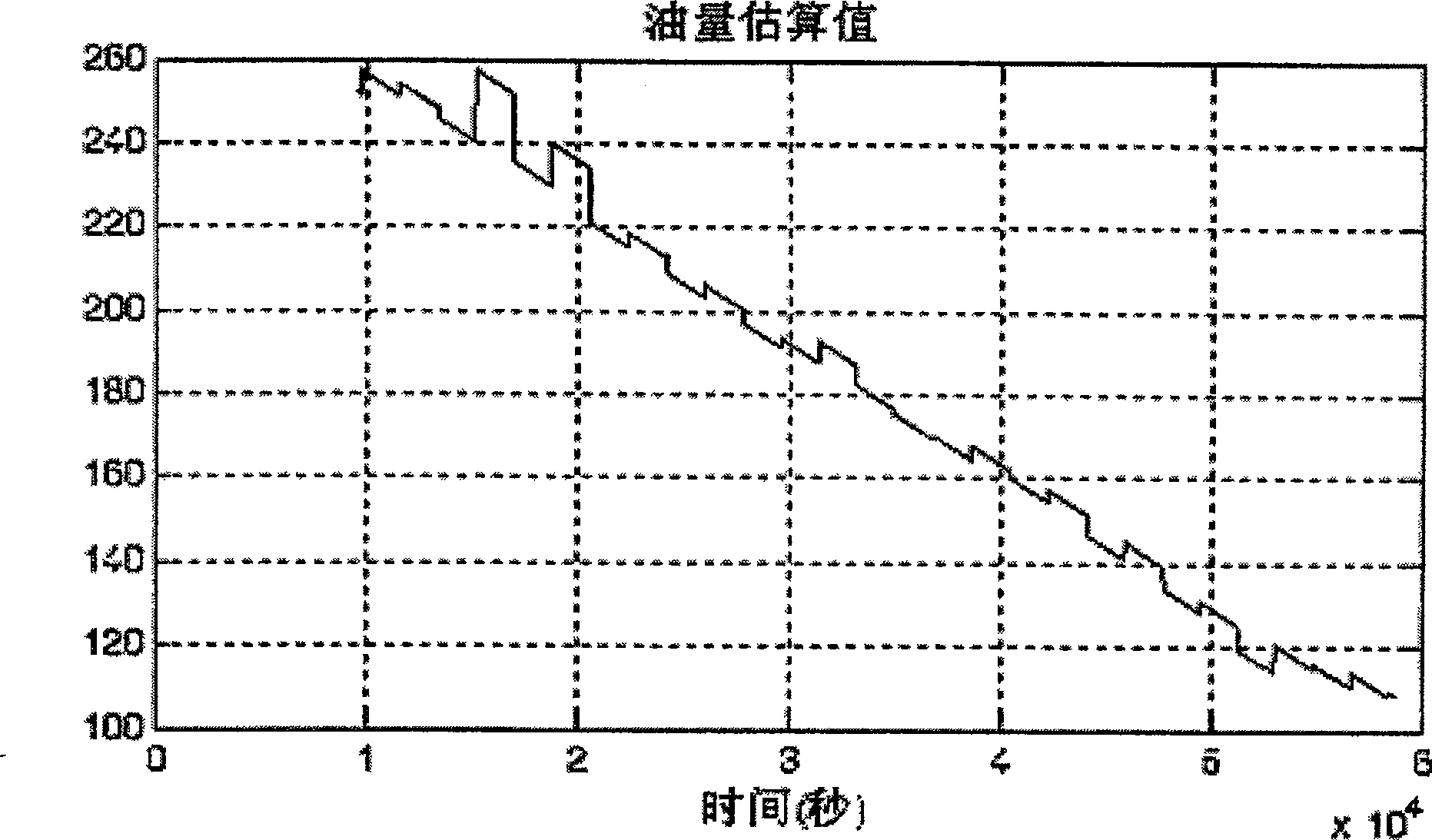

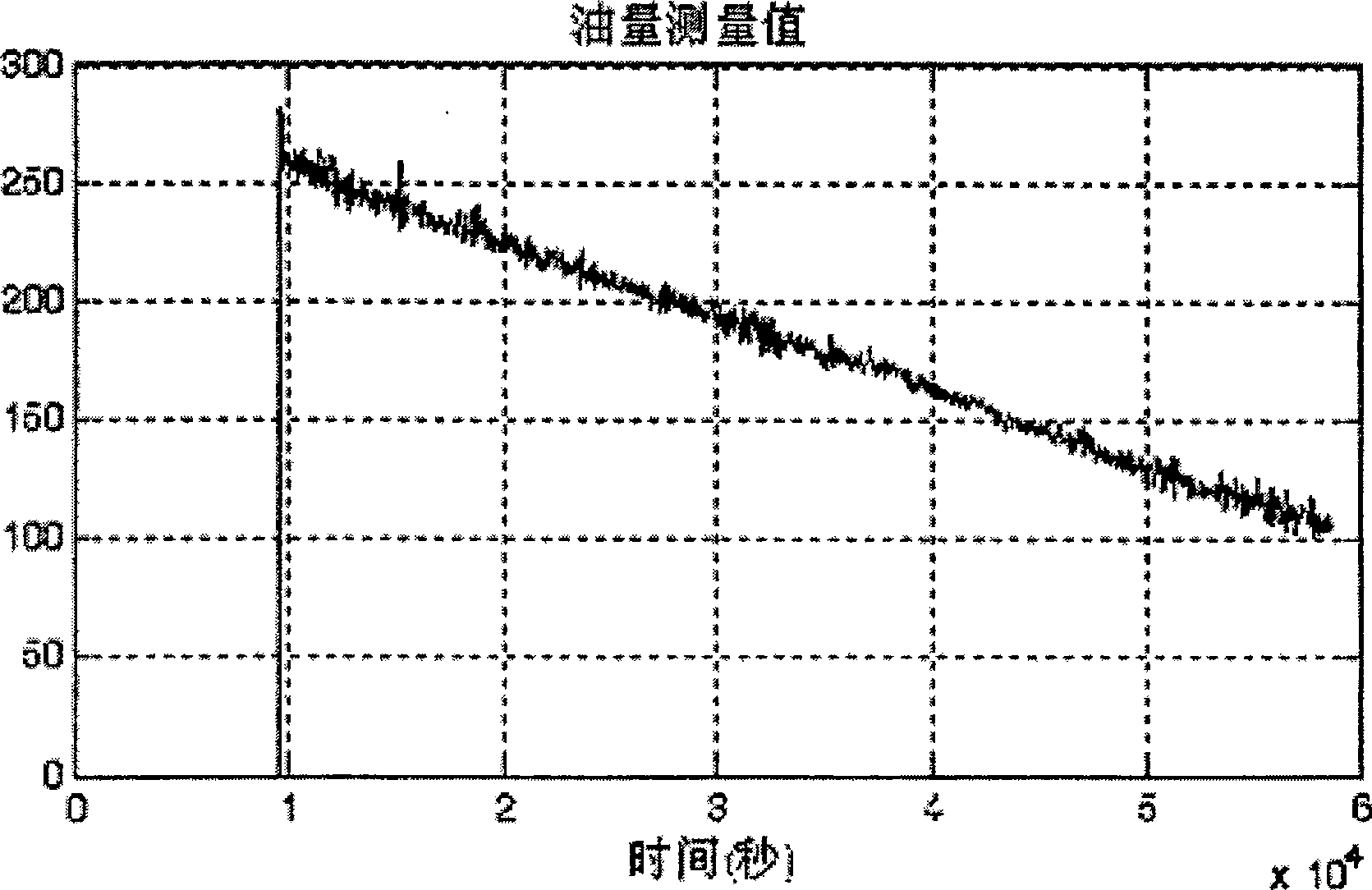

[0037] Example: The method for measuring and correcting oil quantity provided by the present invention will be further described below through the data of specific examples, such as figure 2 and image 3 Shown is a graph of the estimated and measured values of the remaining fuel quantity of the aircraft during a certain flight, using two fuel quantity sensors (models GUC-61 / 1 and GUC-61 / 2 respectively) For real-time monitoring, the specific steps are:

[0038]Step 1: Calculation and correction of engine fuel consumption rate, select several working conditions, and use theoretical analysis method to calculate the fuel consumption rate of the aircraft in these working conditions; oil rate; compare the theoretical analysis and calculation with the ground bench test results, and correct the theoretical calculation method. The corrected theoretical calculation method is obtained, and the corrected theoretical calculation method is bound to the flight control computer for use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com