Sensor for metal liquid comprehensive performance on-line detection

A technology of comprehensive performance and molten metal, applied in the field of sensors for on-line detection of comprehensive performance of molten metal, can solve the problems of large thermal inertia, poor thermal analysis platform ability, strong hygroscopicity, etc., and achieves high reproducibility and reliability. Wide measuring range and low thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

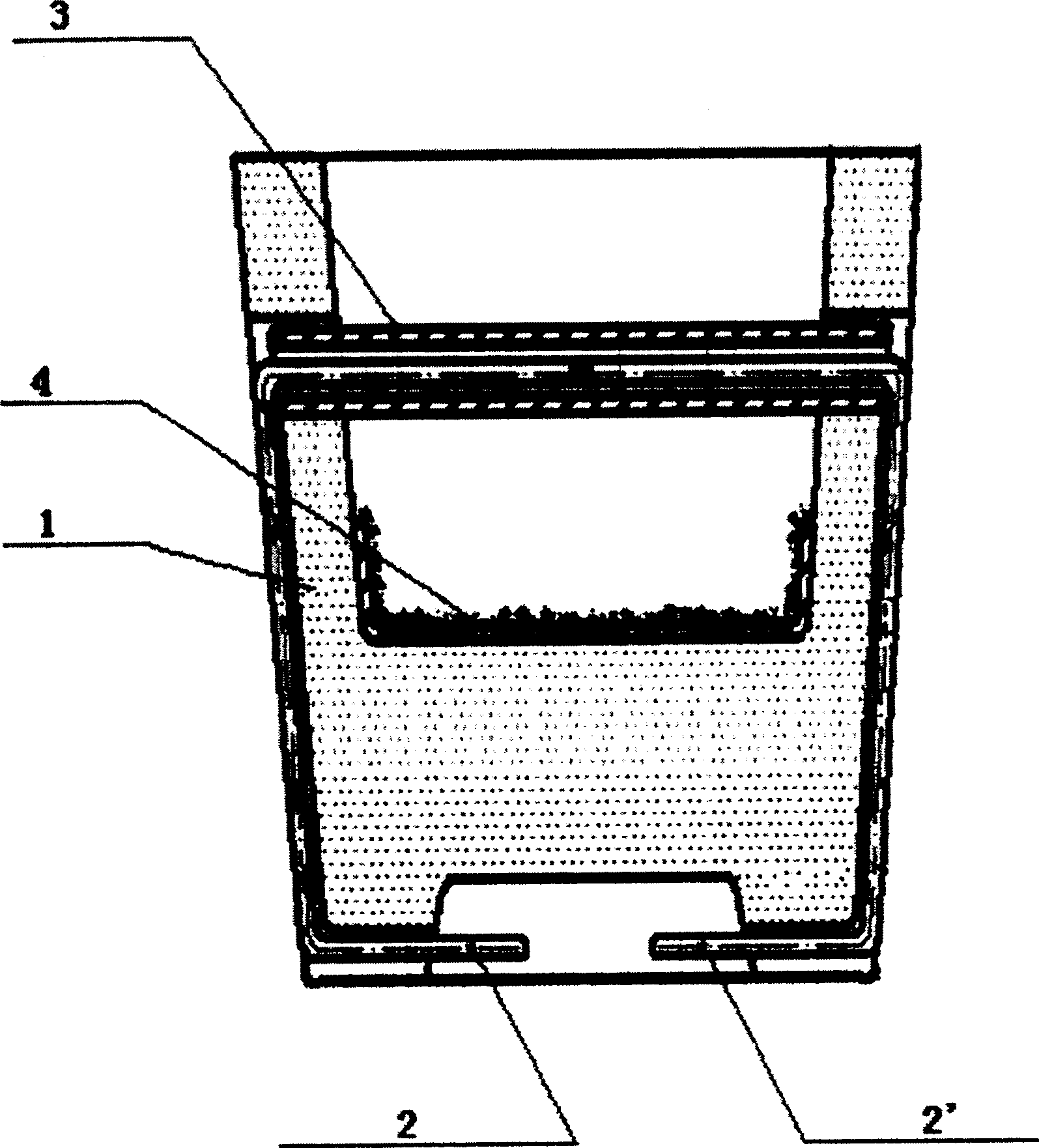

[0012] Such as figure 1 As shown in , the sensor for online detection of comprehensive properties of molten metal of the present invention includes a cup body 1 and a thermocouple. The cup body is in the shape of a square cup and is used for pouring the molten metal to be tested. The thermocouples traverse the cup horizontally so as to be surrounded by the molten metal in the cup, thereby generating an electrical signal related to the temperature change of the molten metal. The thermocouple is connected by K-type precision thermocouple wires 2 and 2' through high-temperature spot welding. The thermocouple wires 2 and 2' are Ni-Cr and Ni-Si respectively, and their free ends are drawn out through the positioning groove at the bottom of the cup body. . The thermocouple is surrounded by a high temperature resistant protective sleeve 3. In one test example, the diameter of the thermocouple wire is less than 0.5mm, the inner diameter of the protective sleeve is not greater than 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com