Frame structure of two-wheels motorcycle

A frame structure and motorcycle technology, which is applied in the frame structure field of two-wheeled motorcycles, can solve the problems of the pivot plate 17 becoming larger, and achieve the effects of shortening front and rear width, improving rigidity, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The best mode for carrying out the present invention will be described below with reference to the accompanying drawings. The figure takes the direction of the symbol as the viewing direction.

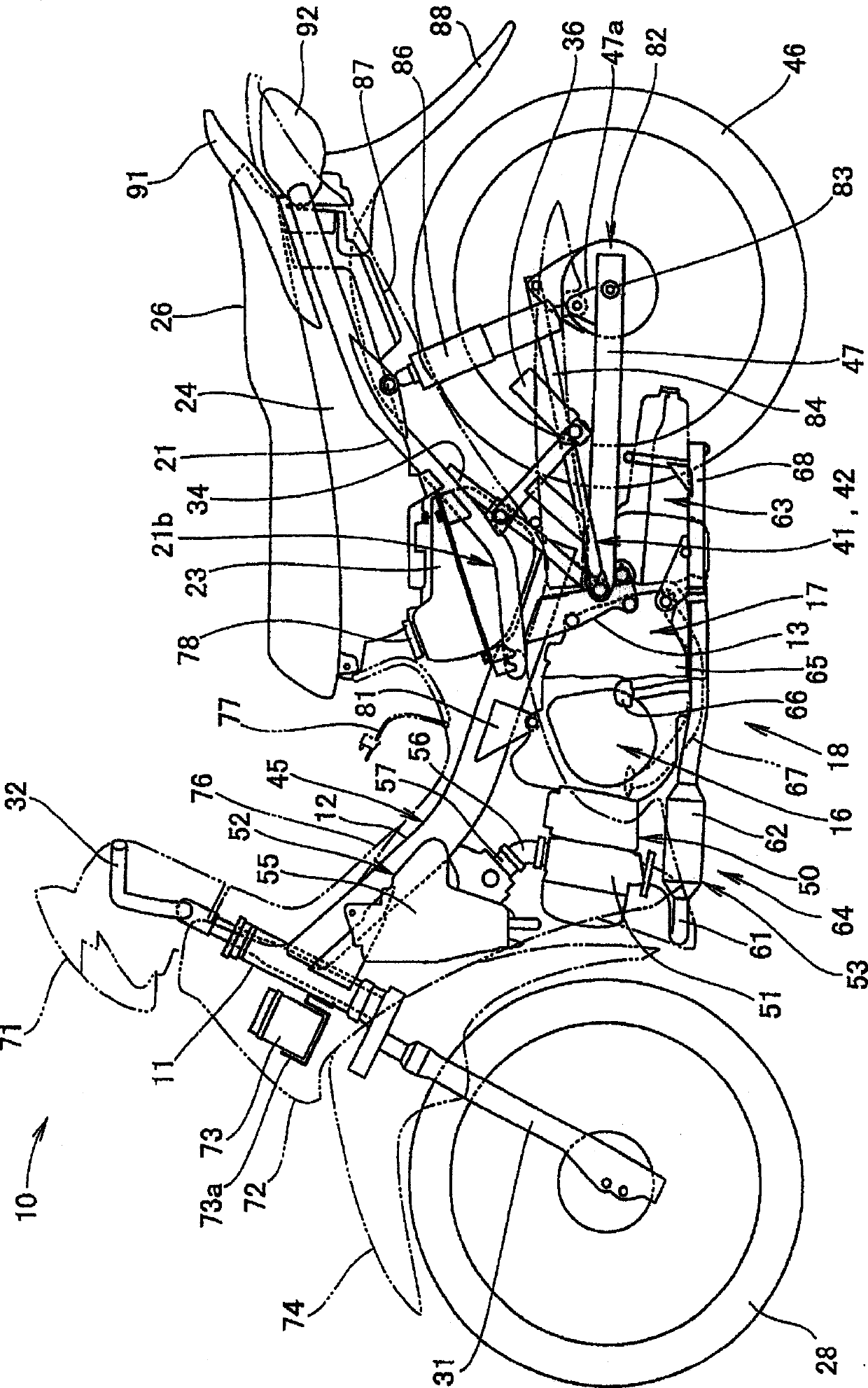

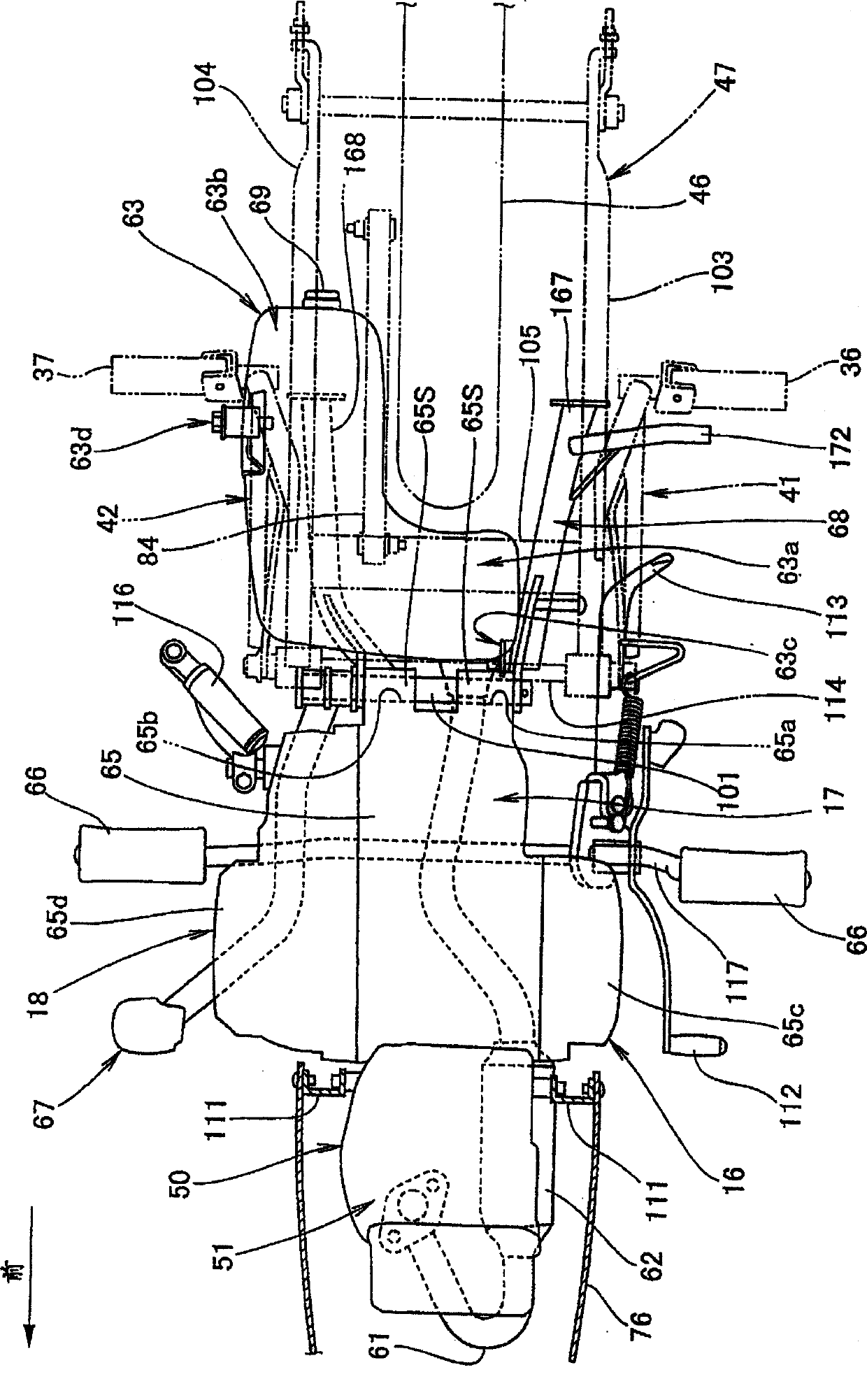

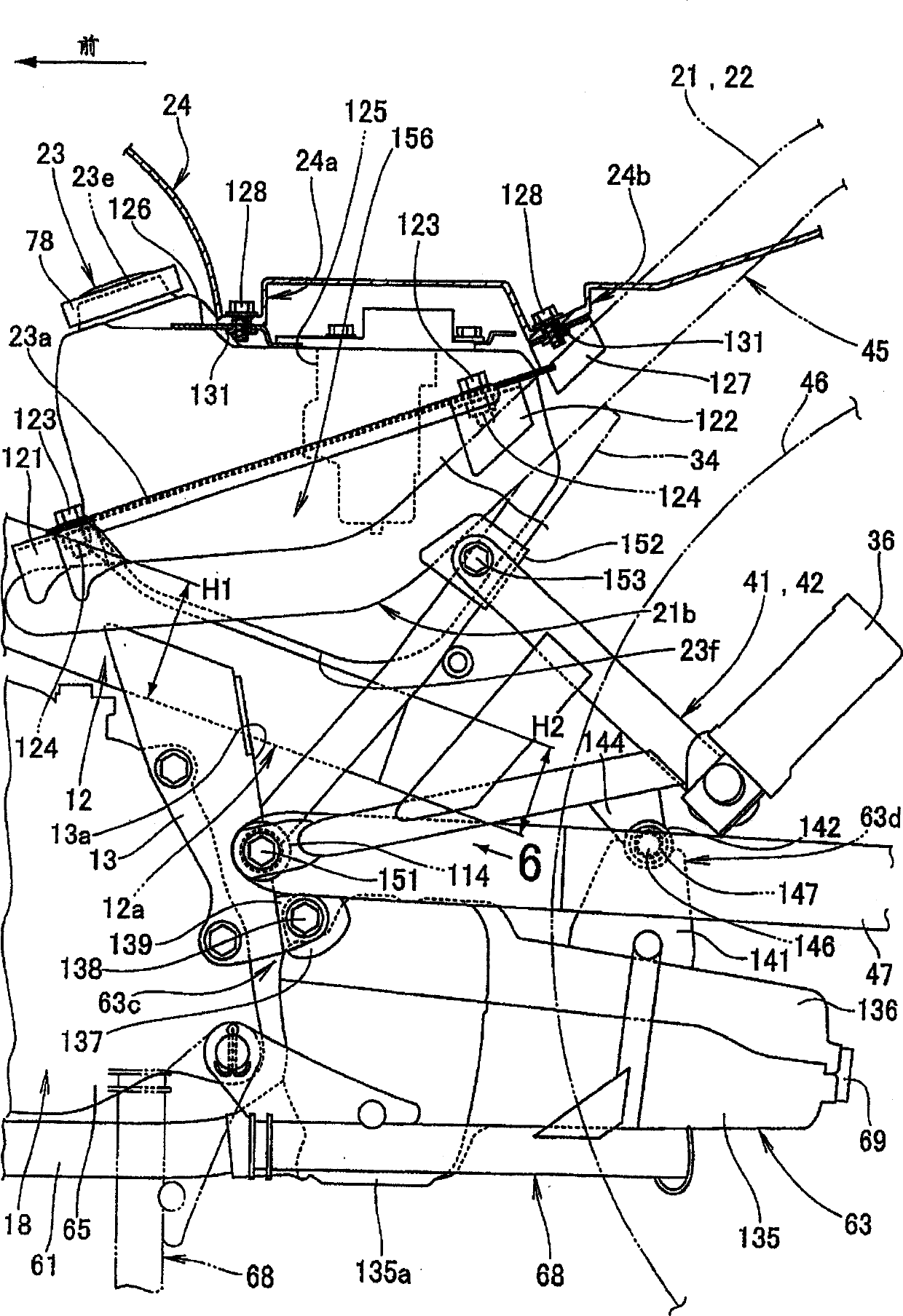

[0051] figure 1 It is a side view of a two-wheeled motorcycle equipped with the frame structure of the present invention. The two-wheeled motorcycle 10 is a vehicle that passes through a main frame 12 extending obliquely rearward and downward from a top tube 11 and downwards. The pivot plate 13 installed on the rear end of the main frame 12 in an extended manner supports the power unit 18. The power unit 18 is composed of the engine 16 and the transmission 17. The oil tank 23 is installed on the rear of the main frame 12. On the left and right paired rear frames 21, 22 (only the symbol 21 on the front side is shown.) extending obliquely upward, the trunk 24 is installed on the fuel tank 23 and the rear frames 21, 22, A tandem seat 26 is attached to the trunk 24 in a freely op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com